On October 14, 2019, according to online “sources,” the first domestically produced Model 3 from Tesla was expected to roll off the line. However, judging from the dynamic updates on Tesla’s official Weibo and WeChat accounts, this momentous event was delayed.

We decided to wait for another day, as our informant indicated that the start of production from Tesla’s Shanghai factory was scheduled for October 15th. However, as you have seen, today is already October 16th, and Tesla China still has the “no more information to share” look.

Although Tesla’s delays are already a tradition, this latest event is sure to rattle the nerves of impatient local Tesla customers. There’s nothing to be done, though, as the only constant at Tesla is change.

We have decided to talk about domestic Tesla today.

Domestic Tesla surpasses imported models in workmanship?

Tesla’s poor workmanship is notorious:)

Many people have vivid impressions of poor workmanship on the Model 3, which was introduced to China early in 2019, such as uneven seams, paint defects, part errors, and even leaking water. However, according to a recent survey by the veteran British auto media “What’s Car?”, Tesla’s reliability ranks fourth among all automobile brands, with only Lexus, Toyota, and Suzuki in front of it.

“What’s Car?” claims that the survey involved 31 brands, 218 models, and 18,119 car owners. However, this is strange. Did “What’s Car?” receive payment, or did the 18,119 car owners?

The truth is that the quality of the Model 3’s workmanship is directly related to whether the production line is in its initial phase or has undergone any engineering changes. The Model 3 models produced by lines that are running in stable conditions are not as bad, at least not as bad as the batch of cars that caused so many problems early this year.

Let’s not talk about the initial production, what is engineering change? Tesla initially produced the Model 3 long-range rear-wheel-drive version, followed by the Standard Range, Standard Range Plus, Mid Range, Long Range all-wheel-drive, Performance, European models, Asia-Pacific models, right-hand drive models, etc…. for the production line, the production of these new models belongs to engineering changes, and the first batch of models will encounter various strange small problems.

It can be said that the first 2000 vehicles (VINs) in Tesla’s global markets are considered to be “unstable” models in terms of workmanship. However, once the production line is operating smoothly and the production capacity reaches 2,500 vehicles per week, the workmanship of the vehicles will gradually improve and become more consistent.

You may ask, why don’t Volkswagen, Toyota, and General Motors have this problem? Moreover, it is widely recognized that the workmanship of American cars is inferior. This is a problem with the enthusiasm and attitude of American workers. The Shanghai factory will definitely not have this problem.

This brings us to the two key factors of vehicle reliability: systematic processes and talent quality.

First of all, truly century-old stores such as Volkswagen, Ford, and Toyota have accumulated complete processes and rich experience in the long-term development process on how to manufacture high-reliability vehicles, which Tesla does not have.

What is a “complete process and rich experience”?

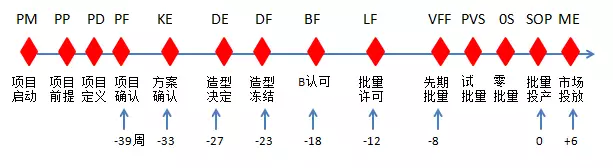

Taking Ford as an example, from the project’s proposal to the production, Ford’s Global Product Development System (GPDS) will go through 6 major stages and 51 nodes. These include 14 project review nodes, 8 appearance review nodes, 13 engine development review nodes, 8 engineering review nodes, 6 vehicle loading nodes, and 2 engine installation verification nodes.

Among the top automotive giants with annual production of over ten million vehicles, the competition is about project management capability, which directly reflects the quality of the entire vehicle. Quality can reflect a car company’s design capability, research and development (many quality problems are planted during the R&D phase) capability, manufacturing capability, and management capability.

In addition, automakers use tools such as FMEA (Failure Mode and Effects Analysis) to conduct systematic analysis on the subsystems, parts, and processes that make up the product during the product design and process design stage to avoid problems in advance and improve the quality and reliability of the product.

So, what about Tesla?Undoubtedly, after nearly a decade of developing three car models, Tesla has also established a systematic process and method for product development, but Tesla’s project management methods cannot be generalized with traditional automotive giants.

First of all, the three elements of project management are quality, time, and cost, which are interdependent and conflicting. For example, to produce a car with excellent workmanship and strict quality control, a lengthy and complete project cycle test and slow production ramp-up are unavoidable.

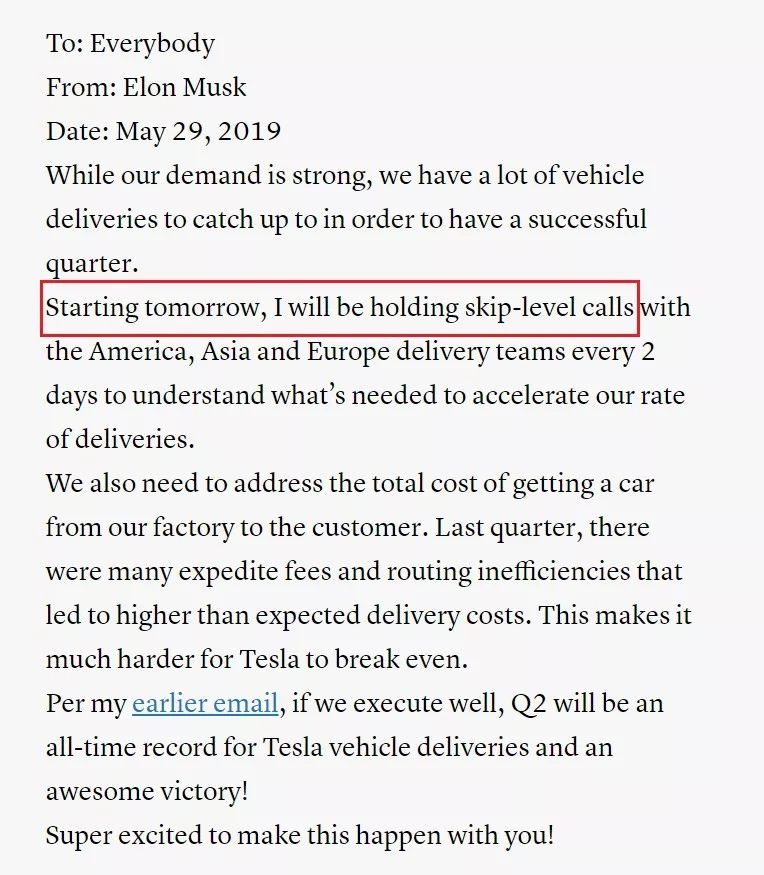

In this regard, we can see that Tesla advocates the Silicon Valley style of “moving fast and breaking things,” i.e., “small steps, quick iterations.” Elon Musk promotes a flat organizational structure, prohibits unnecessary meetings, and encourages cross-level communication. Everything he does explains one thing: Tesla can make concessions for efficiency.

To move faster, higher, and stronger, a limited amount of workmanship can be overlooked. From software to hardware, from initial negative comments to ultimate praises, such reversals are widespread in Tesla car models.

Secondly, talent quality is indispensable. This is the difference between American and Chinese workers mentioned earlier. The same GPDS, whether it is implemented by a negligent or responsible worker, will result in vehicles with completely different reliability.

In this issue, we have reason to believe that Tesla China’s workers will eventually catch up with California’s workers in terms of workmanship. However, on the day when the Shanghai factory just started construction, everything is still unknown.

In summary, relying on Tesla’s genes and culture, placing hope on Shanghai factory vehicles with flawless workmanship is an unrealistic luxury. As for the comparison between the Shanghai factory and the California factory, it is a comparison between 70 and 75 points. Time will give us the answer to which side has better workmanship.

However, when it comes to the first batch of cars released by the factory, the promotion of “beating imported Tesla” is a superficial assumption.

Is the domestic Model 3 with long-lasting power good?

On January 7, when Elon visited China for a media interview, he stated that the Shanghai factory would not produce high-performance cars, only upgraded standard-range and mid-range versions.Many friends have bet that Tesla’s Shanghai factory will eventually achieve full production of Model 3, based on the design capacity of 150,000 units per year for Phase 1 and the competitiveness of the base Model 3.

Taking into account the uncertainty of the workmanship of the initial models mentioned earlier, I am waiting for the domestic long-range version. How long will it take?

Tesla’s California factory is a good reference. Do you know how many vehicles were delivered in the year after the production of Tesla Model 3 started? Let me tell you, 28,395. As of now, Tesla has delivered 23,865 imported Model 3s in China, which means that the annual delivery of over 30,000 vehicles is a foregone conclusion.

Note that over 75% of these 30,000 vehicles are long-range, all-wheel drive, and high-performance models with an average price of over RMB 400,000. What is the potential market capacity for the Shanghai factory’s locally-produced base Model 3, which is positioned lower (with a possible price drop to under RMB 300,000)? How long will it take to digest the orders?

When will it be your turn to have a domestic long-range model?

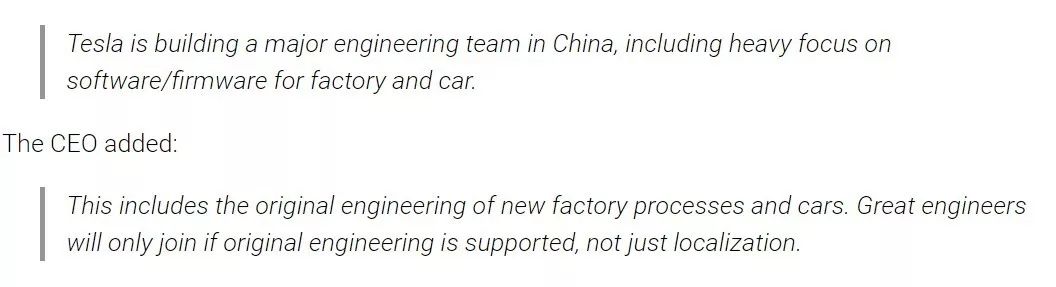

In addition, another piece of news must be mentioned. On September 24th, Elon tweeted that Tesla is establishing an important engineering team in China, dedicated to software/firmware development for the factory and vehicles. The Chinese engineering team will be responsible for prototype engineering work for the Shanghai factory and vehicles. Great engineers will only join when (headquarters) support prototype engineering development, not just some localization work.

Apart from the Shanghai factory, the first project of Tesla’s Chinese engineering team is the domestic long-range version of Model 3 that Tesla’s Chinese management revealed at the owners’ club.

The “wait-and-see” crowd may think that it might be better to wait for the domestic long-range version of the Model 3 stretch version. Maybe the longer wheelbase could accommodate a larger battery pack?

But don’t forget that while the Chinese engineering team is stretching the Model 3, the Tesla headquarters engineering team is vigorously pushing out the Model Y, with limited performance but significantly increased space. You might think that it is still early for Model Y production ramp-up. But don’t forget that the Model 3 stretch version is also part of the “engineering change” mentioned earlier.## What is the best time to buy a Tesla?

We always joke that “Tesla owners who bought early are worse off than dogs” and “buy early and enjoy, buy later and get a discount” is the self-consolation of Tesla owners. However, the fact remains that by introducing the highly efficient development process of the Internet industry and a flat organizational structure into the automotive industry, Elon Musk has achieved a major update for Tesla cars every 12 to 18 months.

So, will the ultimate winner be those who wait? No, those who wait will never have a purchase day because they have lost since the moment they paid.

Speaking of which, are the 28,395 owners who paid for and got their cars this year “fools with money”?

Many people, from Munro & Associates to various technical experts on YouTube, have dismantled Tesla cars, revealing that although the workmanship of every aspect of the Model 3 exceeds the lower limit of the automotive industry, the motor, battery, high-voltage electronic components, and driving-related parts of the Model 3 are all exquisitely made, forming a huge contrast with the appearance and interior that consumers can perceive.

This is very important because it directly reflects whether Tesla’s attitude towards car making is to ignore safety and reliability or to balance efficiency and perfection.

Secondly, and also very importantly: despite all the controversies, at least these owners are driving the world’s most advanced smart electric cars.

Therefore, whether it is domestic or imported is a matter of willing to bear the consequences. For me, the best time to buy a Tesla is June 22, 2012, followed by now.

* Tesla acquires DeepScale, a big player in front-end perception fusion

* Tesla acquires DeepScale, a big player in front-end perception fusion

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.