On July 24, 2019, Tesla CEO Elon Musk announced during the Q2 financial report conference that Tesla co-founder and Chief Technical Officer (CTO) JB Straubel will transition to the role of senior advisor, and Tesla Vice President of Technology, Drew Baglino, will take over as CTO.

This announcement has caused quite a stir.

JB Straubel’s departure means that Tesla is entering a new era. This impact will be even more far-reaching than when Tesla released the Model S in 2012 or when they acquired energy company SolarCity in 2016.

Becoming Tesla’s CTO

Tesla was registered on July 1, 2003, by Martin Eberhard and Marc Tarpenning. However, JB and Elon’s story predates Tesla’s founding.

In early 2003, at McCormick & Schmick’s Seafood Restaurant in El Segundo, Los Angeles, on one side of the table were the co-founders of electric aircraft start-up company Volacom, CEO Harold Rosen, and CTO JB Straubel. On the opposite side was billionaire and CEO of space exploration technology start-up company SpaceX, who had just sold Paypal for a fortune, Elon Musk.

Rosen and JB spent a lunch persuading Elon to recognize that electric airplanes were a great product with enormous potential. However, it seems Elon doesn’t have an interest in all flying tools. The lunch is over quickly, and Elon seems unlikely to invest.

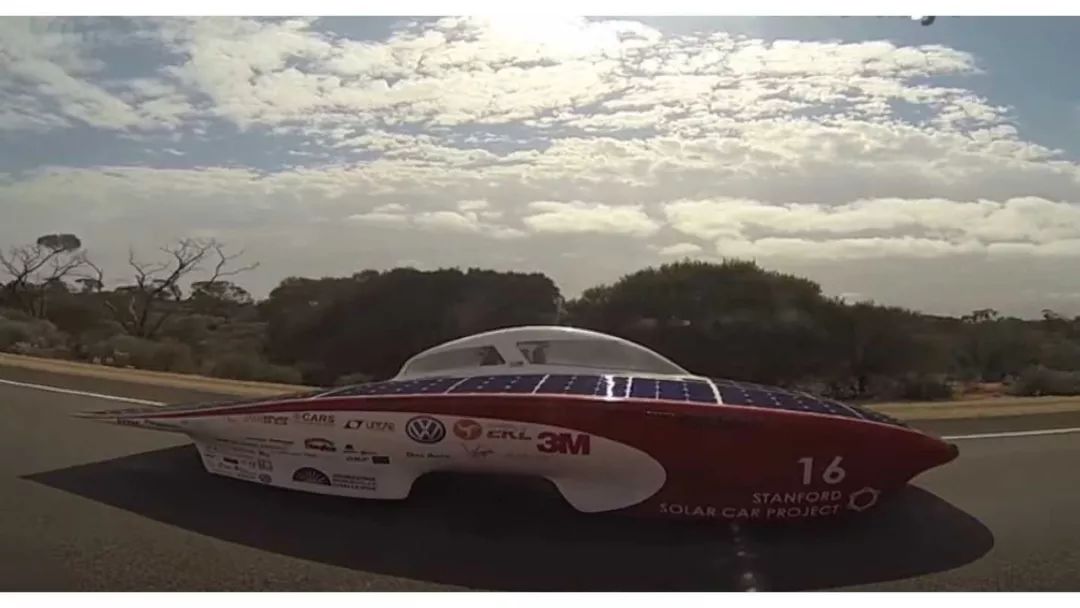

JB mentioned his new discovery: In 2002, he and friends from his Stanford University solar car team researched lithium-ion batteries that were used in laptops and other consumer electronic products. They were convinced that the development potential of lithium-ion battery technology was enough to improve the manufacturing of electric cars. This idea immediately hit Elon, who had been thinking about the commercial feasibility of using supercapacitors in electric vehicles during the few years from dropping out of Stanford to selling Paypal.JB later recalled that in the year or so when he realized that lithium batteries were feasible, he searched for entrepreneurs in Stanford University and Silicon Valley, sending out flyers, writing emails… but everyone told him that the idea was too crazy and this was a bad idea. Only Elon showed great surprise and excitement after hearing the introduction: Sure, I will give you some money.

Meanwhile, in Woodside, North California, Martin Eberhard and Marc Tarpenning were also seeking funding for Tesla. In February 2004, Elon decided to invest $6.5 million in Tesla. In May, Elon introduced JB and the Tesla team (actually Martin, Marc, and employee No. 001 Ian Wright) to each other. In 2008, the aforementioned three people, along with Elon and JB, were all recognized as co-founders of Tesla.

Tesla decided to hire JB with an annual salary of $95,000 and be appointed as Tesla’s CTO at the age of 29.

Roadster’s First Victory

On October 18, 2004, Tesla launched the development of the Roadster prototype based on the Lotus Elise body and chassis, based on the AC Tzero powertrain. On January 27, 2015, the first Roadster built by an 18-member engineering team led by JB rolled off the production line.

JB set two performance parameters for the Roadster: a range of 250 miles and acceleration from 0-96 km/h in under 4 seconds. The real challenge began.

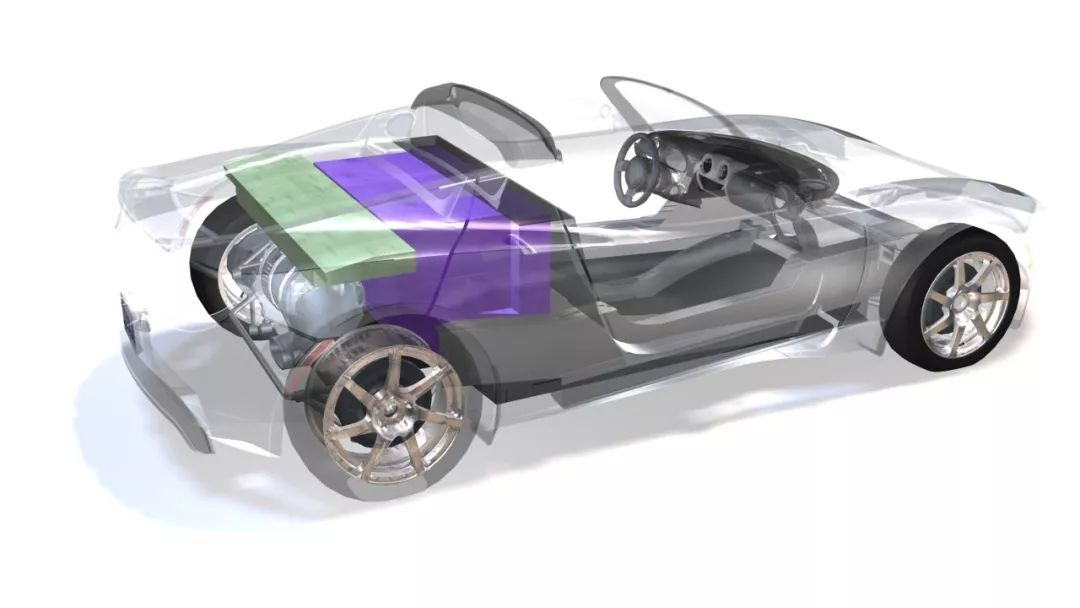

High performance and long range. This is the part that Roadster never compromises. “We want a range of 250 miles, which is the target we set on the first day of the project.” JB’s purpose was clear: Roadster must have performance qualities completely different from low-speed electric vehicles with weak performance and limited range in the public’s understanding.However, the chemical properties of 18650 batteries, which it mainly deals with, are completely different from those of lead-acid batteries it has previously encountered. 6831 batteries with a diameter of 18 mm and a length of 65 mm are spliced together, and their 27 square meters of heat dissipation surface area is 7 times larger than that of 20 lead-acid batteries of the same size.

JB pointed out that the core of the problem is: “As the energy density and quantity of battery cells increase, the problems of the battery pack and thermal management system also increase exponentially.” The result of integrating higher energy density batteries into compact spaces is that instantaneous heat dissipation becomes a big problem. The natural cooling solution originally formulated at the beginning of the project is unsustainable.

JB led the engineering team to develop a complex liquid-cooled battery thermal management system, adding a 50:50 mixture of water and ethylene glycol in the liquid cooling pipeline, allowing the liquid cooling network to pass through almost every battery cell, taking away heat from the rapidly heating batteries. But this leads to a new problem: the increase in the weight of the battery pack reduces the original range of the Roadster to only 170 miles, and worse, there is no obvious culprit for the decline in range.

“This is a typical complex problem without a main solution. You must understand that the ultimate improvement is a systemic improvement brought about by small improvements in various details. By finding 10 or 15 areas for improvement, you can eventually achieve good results.” JB said.

Therefore, the range of the Roadster is gradually improved by tweaking the aerodynamic performance of the vehicle, tire rolling resistance, brake calipers, tire pressure, gearbox…and so on, finally settling at an EPA range of 245 miles, or about 394 km.

Power is another core challenge. Marc, the former vice president of electrical engineering, said, “Most existing electric cars have failed to fully utilize the advantage of the motor’s starting torque over the internal combustion engine, and JB is determined to change that with the Roadster.” However, achieving 0-60 mph in under 4 seconds was underestimated. AC Tzero’s powertrain itself could achieve a time of 4.9 seconds, but the Tesla engineering team overlooked one thing: this was achieved based on a significantly reduced weight thanks to the fiberglass body and structure.

JB was more enthusiastic about promoting the acceleration of Roadster than anyone else in the team. The result was that Tesla acquired a large number of technology licenses from AC Propulsion for a fee, which turned out to be of little significance because AC’s components were expensive and underpowered. In the end, “there is no component similar to AC Propulsion,” says Marc, as JB almost redesigned every powertrain component.

In addition, JB also led the promotion of many major improvements of Roadster, such as carbon fiber body, aluminum frame, single-speed gearbox, and digital controller.

“In February 2008, Tesla co-founder, chairman, and product architect Elon Musk received the first Roadster,” which was a resounding success. At the same time, Elon announced that Tesla’s next sedan, codenamed WhiteStar, would be available at the end of 2009. The new sedan will have two powertrains, a pure electric version with a range of 150-200 miles and an extended-range electric version with a range of 400 miles, of which 50 miles are pure electric. It will be priced between $50,000 and $70,000.

In September 2008, Tesla announced that it had discontinued the extended-range electric version and was fully committed to developing the pure electric version in order to unify the power battery route and reduce the complexity of the powertrain. However, even so, the overall innovation of Model S has greatly delayed the project cycle. These innovations include but are not limited to the industry’s first integrated 17-inch central control touch screen, dual Linux systems, the lightest and most robust white body among peer cars, and over-the-air updates, all of which were promoted by JB’s team.

In August 2009, Tesla announced the 7-seat sedan named Model S, which was delayed until the end of 2011. The first two versions had a range of 160 and 230 miles respectively, while the third version in 2012 reached an unprecedented range of 300 miles.

In August 2009, Tesla announced the 7-seat sedan named Model S, which was delayed until the end of 2011. The first two versions had a range of 160 and 230 miles respectively, while the third version in 2012 reached an unprecedented range of 300 miles.

During an interview, JB stated that the battery spec for the 2012 version could reach 85-90 kWh. “I don’t want to give a definite specification, but it will definitely be the largest battery pack on the market. We are designing and manufacturing it ourselves.“

From the beginning, the 17-inch touchscreen was a key design point. “At Tesla, the human-computer engineering usability, entertainment technology, powertrain, and acceleration performance are equally important. We have a strong team of software engineers to achieve this.” JB said.

According to JB, Tesla has put a lot of effort into software engineering, which is reflected not only in the smoothness of the central touch screen but also in the fast and smooth response of the accelerator pedal. “Tesla has written most of the Model S software system code and completely separated the central entertainment system and dashboard driving control system.” “You can turn off the large central screen if you want, but it won’t affect the driving of the vehicle at all, just the display of the map.“

In terms of manufacturing, the Model S factory changed from the New Mexico Albuquerque factory and California San Jose factory in April 2007 to the Fremont factory acquired in May 2010.

On January 1, 2012, the world’s first Model S drove out of the Fremont factory and was delivered to former Tesla director and investor Steve Jurvetson. All members of the White Star team made a gesture “1” together.One year later, the Model S won the World Green Car, Motor Trend, Automobile of the Year, and was named one of Time’s 25 Best Inventions of the year, with Consumer Reports giving it their highest score ever…

The Model S was a success.

Gigafactory 1 & Supercharging stations

When asked what Tesla’s top priority was, JB blurted out: “Batteries.” The Model S was a truly transformative product and Tesla had reached a critical point. On the one hand, it had a range of 300 miles, but on the other hand, battery energy density was improving rapidly at a rate of 7% to 8% per year.

“In ten years, the weight of a battery pack with the same specs will only be half of what it is today,” said JB.

After a year of ramping up production capacity, by early 2013, Model S production had reached 550 vehicles/week. Elon and JB did a simple calculation of how many kWh of batteries one car needed and how many GWh of batteries were needed to sell 500,000 cars a year.

The simple math stunned Elon and JB. Demand for 35 GWh/year would exceed the total demand of all batteries in the global markets for cellphones, laptops, and electric cars combined.

“No one can solve this problem unless we build an entirely new facility ourselves,” said Elon.

In November 2013, Elon told analysts that in order to ensure a stable supply of batteries for the Model S, the forthcoming SUV Model X, and the third generation of Tesla vehicles (Model 3/Y), he was envisioning “a truly giant facility, a factory that is as large as the current worldwide production of lithium-ion batteries.”

Tesla’s execution is not to be doubted. In May 2014, JB revealed that Gigafactory 1 had been finalized and Tesla would break ground in the coming weeks. Giga 1 “will double the worldwide production capacity and reshape the supply chain through a single factory.”JB mentioned his obsession with batteries: in the 1990s, lead-acid batteries were the most advanced technology for electric cars. “Lithium-ion batteries changed the game in terms of range, energy density, and cycle life. This is a key factor for Tesla’s success. The improvements in battery technology over the past decade have been amazing.“

In 2018, Model 3 production was in hell, and automotive media around the world knew that Elon was living in the Giga 1 factory to improve production capacity. But what is unknown is that “Shortly after the groundbreaking of Giga 1, JB moved directly into a trailer among the rocks, soil, and building materials until the end of 2016, when Giga 1 was officially put into production.“

During his time away from Giga 1, JB allocated most of his time to the Fremont factory and California office. He had been obsessed with lowering equipment capital expenditures and battery manufacturing costs per GWh and kWh.

When it comes to the differentiation advantages of Model S compared to other electric vehicles, JB mentioned the Supercharger station. Even the first-generation 90 kW Supercharger was more than twice as fast as the charging speed of electric vehicles at that time. If any part of the battery thermal management system, charging pile independent protocol, and grid connection was not adapted, Supercharger could not be implemented.

In June 2013, Tesla showcased the technology of changing batteries in 90 seconds. But in June 2015, Tesla announced that the expansion of battery swapping stations would not continue. “Behind this decision was JB stopping the battery swapping line and pushing the Supercharger line.” His software team reserved fast charging capacity before expanding the Supercharger network. With the construction of charging stations, the long-distance travel experience of Model S/X has gradually improved.

Under this guiding concept, today, ten years later, Model S/X has upgraded supercharging power to 200kW under the third-generation Supercharger.

Elon Musk & JB Straubel

There would be no Tesla as it is today without JB.

没有 JB 就没有特斯拉的今天。# This is what Tesla employee Gene Berdichevsky says about JB #007. How does Elon evaluate JB’s work? “Without that lunch in 2003, Tesla wouldn’t exist.”

At least three employees expressed similar views: Elon and JB are two extremes. Elon is imaginative and resolute, and most of the time he is the star of the Tesla stage.

JB recalls that Elon is a very tough guy, and he is an incredible combination of challenges and difficulties. He is deeply committed to our mission, whether it is Space X, Solarcity or Tesla.

“He has a drive and passion that I have never seen before. He is competitive and leads by example, working harder than anyone else and expecting everyone in the company, wherever they are, to work as hard as he does. “

He is a perfectionist, so it is difficult for you to work with him if you are his employee, but this will make you better. I’ve seen it for almost 12 years and the results are self-evident.

“He drives himself forward with blood, sweat and tears, facing higher risks than anyone else, I have great respect for everything he has done. Without Elon, nothing can move forward. “

JB is the opposite of Elon, he is passionate but gentle, and most of the time he is happy to let Elon take the stage. Unlike Elon, who crossed the smart electric car industry from the internet/aviation space, JB’s lifelong passion was dedicated to electrification.

“Before the world started paying attention, JB has always been a missionary and visionary of electric cars.” Berdichevsky said.

JB is a natural engineer, and most of his energy is spent solving engineering problems. There is no music on his iPhone, and he can even drive for eight hours without listening to a song. On the contrary, he believes that “silence is great, electric cars have no big noise, and you can think and solve some problems while driving.”

Former Tesla Chief Battery Scientist Kurt Kelty said that when a solution does not work, JB can stop and think, and change the direction of his efforts. “Not only can he change direction himself, he can also unite everyone around him to support the new direction.”# Tesla’s R&D Process and Post-JB Era

Tesla’s R&D process is not always smooth. On the contrary, there are often stumbling blocks along the way. This is where JB’s leadership skills proved invaluable.

Elon and JB’s personalities complement each other so well. This is the fundamental reason why they have worked together perfectly for the past 16 years and led Tesla to where it is today.

Post-JB Straubel Era at Tesla

In May 2014, JB publicly commented that the most advanced power battery in the 1990s was the lead-acid battery. He had the right to speak in the battery field because he had built two lead-acid battery electric vehicles before joining Tesla.

This Schwinn electric mountain bike has a curb weight of 31 kg and a system voltage of 24 V, powered by two 17.2 Ah lead-acid batteries. It can reach a top speed of 51 km/h and has a range of 48 km (assisted by pedaling).

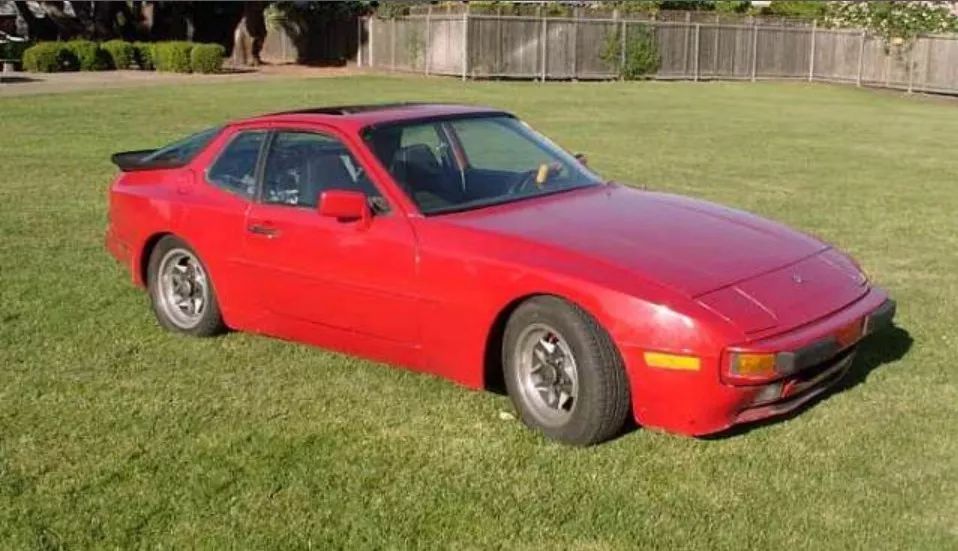

After trying his hand at the bicycle, he spent $1600 on a second-hand 1984 Porsche 944.

This electric sports car has a curb weight of 1409 kg, a system voltage of 240 V, and a top speed of 176 km/h. It has a pure electric range of 48 km. This car broke the world record for electric car acceleration with a time of 17.28 seconds in the 1/4 mile acceleration race held by the American Electric Car Racing Association.

You may think that JB was able to become Tesla’s CTO at the age of 29 because of his innate engineering talent. But what I want to say is that this also foreshadowed his eventual departure from Tesla.

During his studies at Stanford, JB created a major called “Energy Systems and Engineering”, which “allowed me to combine computer science with power electronics. This was all the field that I was interested in.”

Therefore, for the past 16 years, Tesla’s CTO was an executive with zero vehicle engineering background.JB, who did not have a background in vehicle engineering and had no experience in the automotive industry before joining Tesla, is that a problem? Apple co-founder Steve Wozniak also had no experience in developing computers before creating the Apple I and Apple II, but that did not affect Steve Jobs’ leadership in making Apple a benchmark in the consumer electronics industry and the world’s most valuable company.

However, JB and Wozniak’s circumstances are quite different. Apple was to a large extent one of the pioneers in the PC industry, while by the time Tesla was founded in 2003, the automotive industry had been developing for more than 100 years, accumulating a lot of technical knowledge.

JB’s lack of professional understanding of vehicle engineering is one of the reasons why Tesla did not achieve a high-quality driving experience in terms of chassis quality, NVH, and handling until the delivery of Model 3 and the 2019 Raven version of Model S/X.

At the same time, Tesla’s growth and challenges outside of technology have made it increasingly difficult for JB to adapt. “Tesla has evolved. What we need now is a focus on sales, delivery, and manufacturing. I have been helping to solve these problems for the past few years, but this is not what I am best at. There are many people in the world who are better at these issues and enjoy the process more.”

For most larger automakers, there is no CTO position that combines multiple roles and oversees all technologies. As the automotive industry continues to transform, the management difficulties of all automakers are increasing and the complexity of technology is constantly rising. A CTO of a powerful automaker needs a profound understanding of power electronics, vehicle engineering, energy management, software engineering, and autonomous driving–Tesla’s new CTO Drew Baglino is just that.

Drew has been working at Tesla for 14 years, and when he first joined, JB’s technical team had only 5-10 people. JB referred to Drew as his “Right-hand Person,” the man who “participated in the development of every key strategy at Tesla.”# Drew leads all subdivision technical fields of energy products engineering, three-electricity, powertrain, power electronics, high voltage and battery safety in Tesla. Given Tesla’s vertically integrated development strategy and business complexity, such a technical all-rounder is obviously appreciated by Elon. Elon’s own evaluation is that Drew’s team has played a key role in power system innovation, factory innovation, solar roofs and many other areas.

In the latest personnel adjustment, Drew began to concurrently serve as the head of Autopilot’s path planning. All subdivision technical fields in Tesla have two figures, one is Elon, and the other is Drew.

“If there is anyone among the early employees who can take over JB’s mission and lead the technical team forward, it is Drew.” Berdichevsky said.

As for JB, he has already created history—the Roadster he handed over to Elon in February 2008, ten years later, broke free from Earth’s gravity with the Falcon Heavy and forever shuttle in space.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.