June 27th, NIO released the “Statement about the Partial Recall of ES8”. Huang Chendong, the Vice President of NIO Electric Power Engineering, made a statement on the NIO App called “Clarification on Battery Recall”, and then NIO’s power battery supplier CATL also released the “Statement about NIO’s Partial Recall of ES8”. The intensive information and seemingly conflicting statements from all parties have aroused widespread discussions, but NIO’s original intention of transparency and openness could not be achieved.

Many users left messages on the NIO App and raised many new questions. We have organized the background and details of the recall, and presented them in a question-and-answer format as follows.

Q1: How to understand the differentiated statements in the two parties’ announcements?

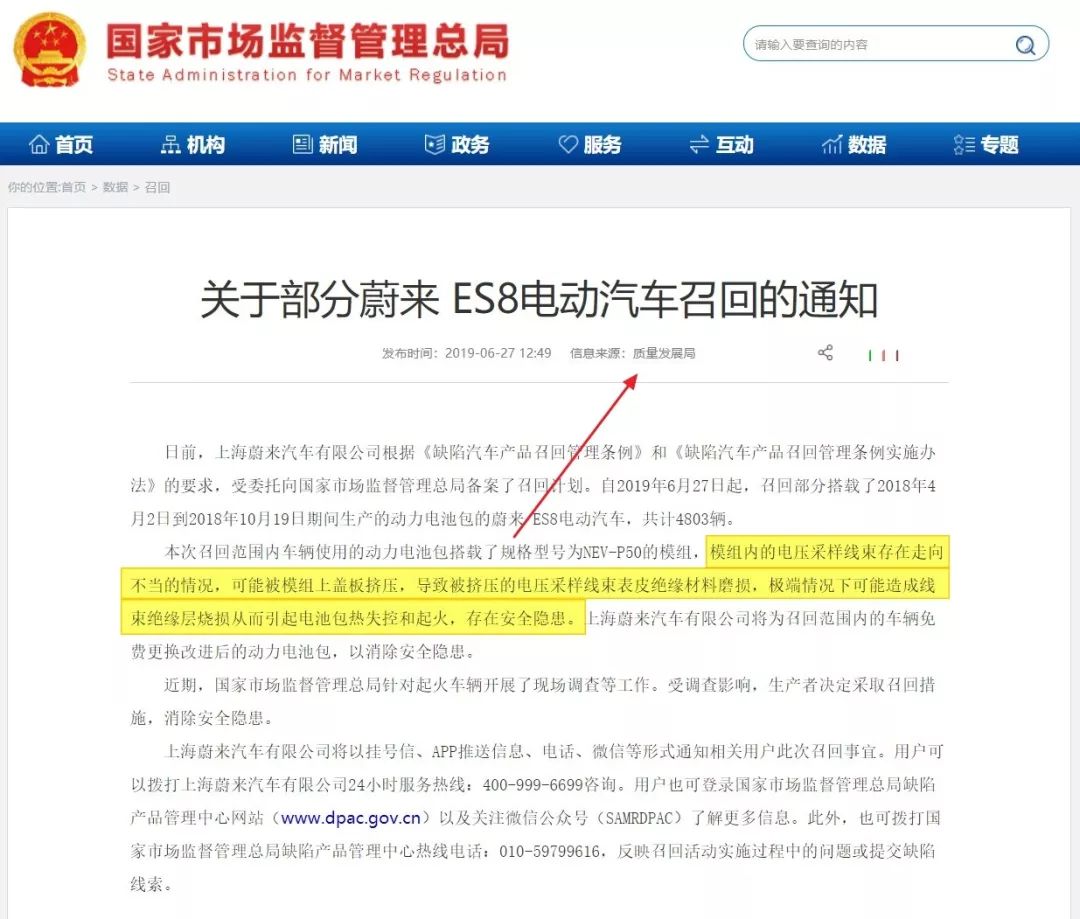

A1: In the NIO statement, we saw that the safety hazard lies in the “possible squeezing of the sampling harness in the module due to individual wire routing errors and the cover plate of the module”, while CATL’s description of the safety hazard is that “the battery pack box body and the structure of the module supplied by our company (CATL) interfere with each other and may cause a risk of short circuit of the low voltage sampling harness under certain extreme conditions”.

Regarding this issue, we directly posted the notice of the State Administration for Market Regulation on the recall of some NIO ES8 electric vehicles, and we can see that the description of the safety hazard is exactly the same as that of NIO, but the information source is not NIO, but the Quality Development Bureau.

In the statement below, we see that “the investigation agency for the vehicle fire is the State Administration for Market Regulation”, and NIO’s statement also mentioned that “industry technical experts, battery pack module suppliers, and other parties participated in the accident investigation jointly with NIO’s investigation team”.

In the communication between Garage 42 and CATL, CATL also replied that “CATL and NIO have reached a consensus on the investigation conclusion of this matter, and both parties have identified that there is a risk of wire harness being squeezed in the module. CATL further explained that the reason for squeezing is interference”.

At this point, we can confirm that according to the investigation report issued by the regulatory authorities and recognized by all parties, the safety hazard comes from the improper routing of the voltage sampling harness inside the battery module provided by CATL, and CATL needs to bear the main responsibility. As the integrator of the whole vehicle, NIO did not detect the safety hazard in the process of integrating safety verification in a timely manner and should bear joint liability.

Q2: Will the cost of this recall and full replacement of battery packs be borne by NIO?A2: According to industry insiders, in general, for defective products, OEMs will first complete the recall and then trace back to the supplier. As long as the vehicle is within the warranty period, related suppliers must bear any vehicle failure caused by component quality issues. Regarding the recall costs, NIO and CATL will negotiate and decide. According to the report from the General Administration of Quality Supervision, Inspection and Quarantine, unless a special agreement is signed, the materials, labor and subsidies invested in the recall by NIO must be traced back.

Q3: Will NIO make any other investment regarding the recall incident?

A3: Yes, NIO mentioned that a cross-departmental action team has been established to continuously optimize the quality management system of products in collaboration with related supply chain partners.

What is more serious than the recall itself is the series of spontaneous combustion-recall, which greatly impacts the brand value of NIO. Since 2015, NIO has invested comprehensively in brand building, creating the first luxury brand with an average product price of around 400,000 yuan in China. The series of spontaneous combustion incidents now has a serious negative impact on NIO’s brand image among potential consumer groups.

Consumer confidence is more important than gold.

Q4: What is NIO’s comment on the ES8 smoking incident in Shijiazhuang on June 27?

A4: After preliminary investigation, the battery modules of both the accident in Shijiazhuang and Wuhan belong to the P50 module specifications. Whether the cause of spontaneous combustion comes from the safety hazards of the P50 module is still under investigation. Zhu Jiang, Vice President of User Development of NIO, said, “The investigation that should be done will be conducted step by step rigorously and will not be omitted due to the recall.”

Q5: What does it mean by “customized design” mentioned in CATL’s statement?

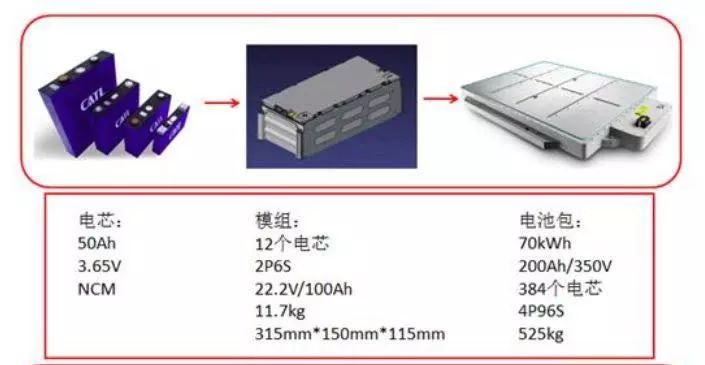

A5: P50 is a power battery module developed by CATL in the early days. NIO undertakes all investment costs for development, mold, and production line equipment, so besides NIO, no other brands use the P50 battery.

(Answers below come from NIO’s official reply)

Q6: Some users have received four notices – recall, no recall, recall, and no recall – and feel that NIO has been flip-flopping in the process of confirming the P50 battery. Could you provide more details on how to trace this batch of batteries to ensure that all P50 batteries are recalled?

A6: NIO records every battery in the battery swap system and keeps precise traceability.After the preliminary conclusion of the accident in Shanghai, before the national official recall approval, for safety reasons, we isolated the battery pack carrying the NEV-P50 module in the battery swapping system. At the same time as the declaration was sent, we have notified users through APP push and SMS that each user within the scope of the recall will receive one-to-one communication subsequently.

Q7: Some users reported that the ES8 manufactured in September is equipped with a 102 Ah version of the battery pack, while the app of NIO said that 102 Ah was not launched until October 20. How does NIO explain this issue?

A7: Since October 2018, our supply chain partner’s NEV-P50 module has been switched to NEV-P102 module. We have announced the reason for the switch on the NIO app on October 20, 2018. Based on NIO’s unique battery swapping system, replacement is possible during our users’ energy supplement, maintenance, and overhaul processes.

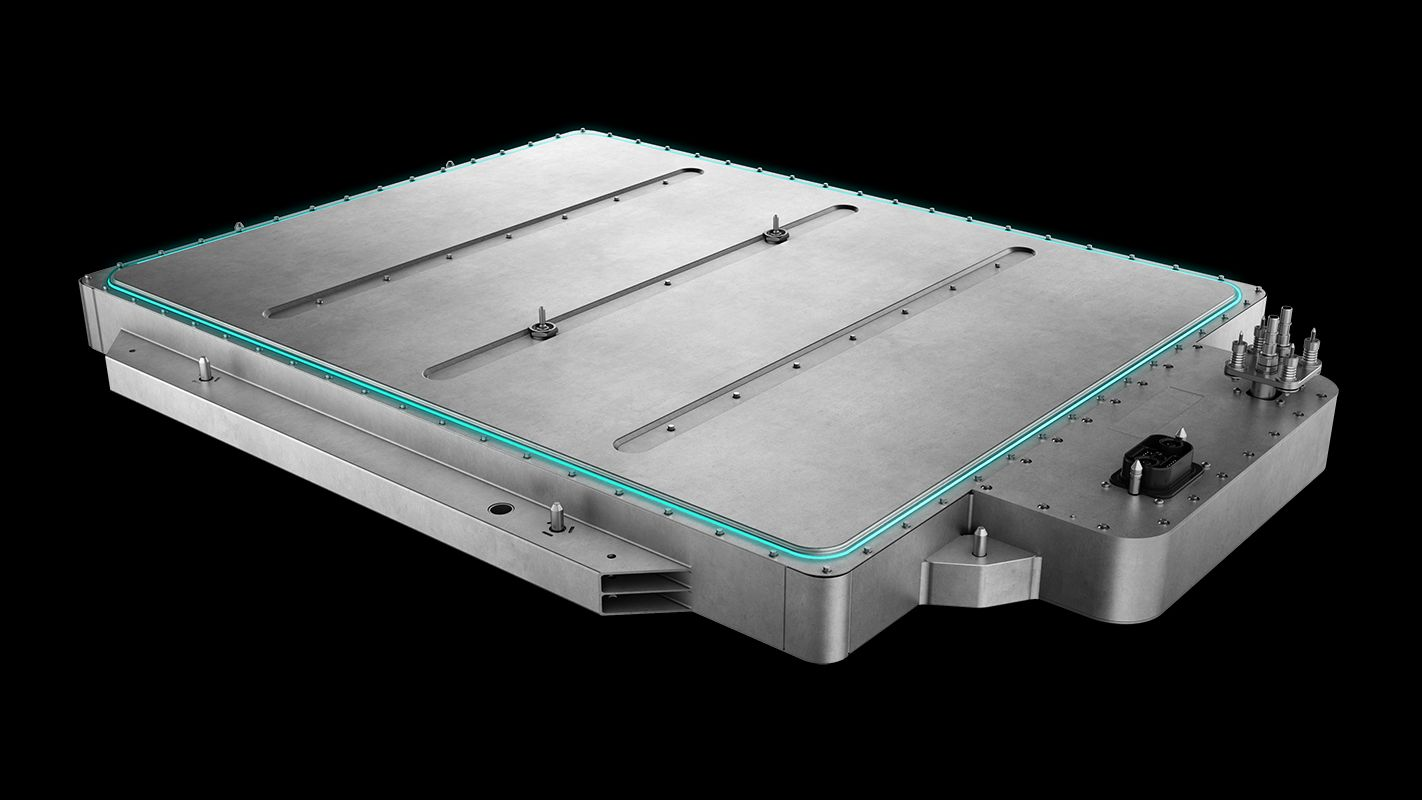

Q8: Can you give a more detailed introduction to the structural differences between 102 Ah at the module and Pack levels?

A8: Compared with the 50 Ah specification battery cell equipped in the NEV-P50 module, the 102 Ah specification battery cell has double the volume and slightly more than double the capacity. When the number of modules is the same and the size of the battery pack is the same, the total energy of the battery pack equipped with the 102 Ah specification will increase by about 2.8 kWh compared to that equipped with the 50 Ah specification, and the actual available mileage will slightly increase.

As the battery technology evolves, our partner provided us with different solutions. After joint research between both parties, the battery module was switched from NEV-P50 to NEV-P102. We made an announcement on the NIO app on October 2018 regarding the adjustment of the ES8 battery pack specification.

The internal structure of the NEV-P102 module adopts a different design, and there is no risk of voltage sampling harness being squeezed and worn.

Q9: “Compensation shall be made according to the law for all user property losses caused by battery quality and safety accidents.” Can you explain the “compensation plan?”

A9: The specific compensation plan will be customized according to specific cases.

Q10: Are batteries that are not within the scope of the recall safe to use?

A10: Those not within the scope of the recall can be used with peace of mind.- The voltage sampling harness in the 50 Ah module is not completely restrained and may be squeezed by the module cover, which may cause insulation layer wear and short circuit, posing a safety hazard.

- The 102 Ah module uses a flexible circuit board for sampling without a harness and is well fixed. The design is completely different, so there is no such risk.

42HOW Review

Brand building requires continuous efforts, but destroying a brand can happen in an instant. What NIO has lost in this series of accidents is the trust of consumers in NIO’s technology control capabilities.

NIO mentioned that there is no risk of voltage sampling harness being squeezed and worn on the P102 module and explicitly stated that they did not know about the safety hazard of the P50 module during the initial switch.

So, does the P102, which eliminates the above risks and uses a different process design for its internal structure, imply potential new risks?

According to industry insiders, the reason for the risk of harness wear and tear due to squeezing is that the pack structure design is too compact, and there is not enough space for battery expansion. So, does the 84 kWh battery pack of NCM 811 with higher energy density, stronger activity and updated structure design, imply new risks?

This is not just NIO’s problem. Tesla, BYD, GAC new energy, XPeng, Ai Chi, Skyline, Hezhong, Jinkang… all have already/are about to launch large battery specifications and high-energy-density pure electric vehicle enterprises. Have they done sufficient validation testing for vehicle integration?

In fact, before the recall announcement, concerns about the high energy density of the battery, which was strongly tied to subsidy policies, and the resulting reduction in pack structure weight (reduced safety), had already raised concerns among many commentators. In the discussion of the spread of thermal runaway incidents, senior practitioners, such as President Zhu, pointed out that (globally) many places have done well in proposing battery safety standards and thermal runaway experiments. Why is there still a series of fire incidents? We must have made a wrong choice at a key point.

Of course, the premise for us to analyze the NIO recall problem in detail here today is that, NIO has fully disclosed the details of the investigation and subsequent solutions. After the recall statement was issued, NIO’s automotive chairman Li Bin, User Development Vice President Zhu Jiang, Electric Powertrain Engineering Vice President Huang Chendong, Power Management Vice President Shen Fei, and Senior Director Liu Haisong of the After-Sales Quality Department stationed themselves in the NIO App to answer user’s questions.

The first step in eliminating consumer concerns and rebuilding consumer confidence is to have an open and honest dialogue with users. This sentence is not for NIO only.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.