After being bombarded by continuous SMS, phone calls, and pop-up notifications from new energy vehicle companies, we have finally welcomed the moment when the subsidy officially declines. Starting on June 26, we will officially enter the 2019 new energy vehicle subsidy policy, and this will have a huge impact on the entire automotive industry.

More Than 50% Subsidy Decline

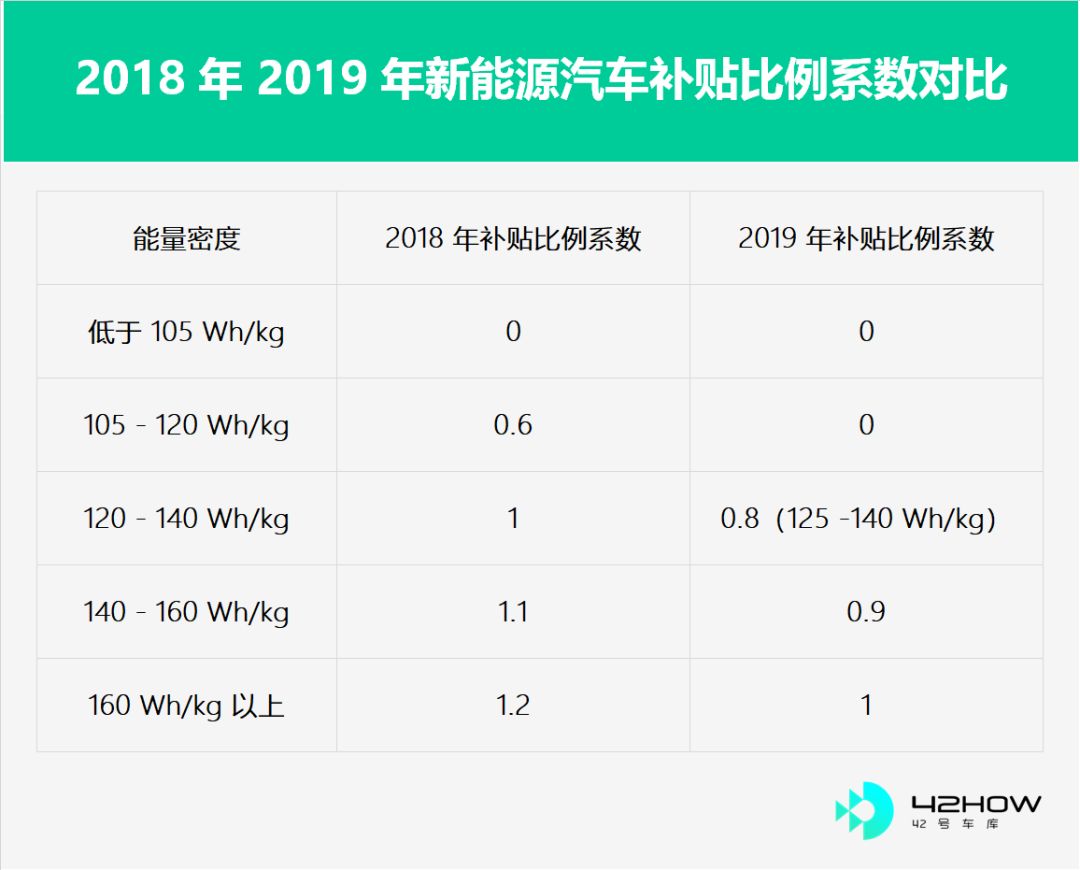

On March 26, the Ministry of Finance, the Ministry of Industry and Information Technology, the Ministry of Science and Technology, and the National Development and Reform Commission jointly released the 2019 new energy subsidy policy. Let’s review the subsidy policies of 2019 and 2018, as well as the differences between the two.

Compared with 2018, the subsidy policy of 2019 has raised the minimum driving range threshold from 150 km to 250 km while reducing the subsidy amount by half. The subsidy for plug-in hybrid vehicles has been reduced from 22,000 yuan to 10,000 yuan. In addition, regional subsidies have been canceled, and local governments are required to invest subsidies in strengthening local new energy vehicle infrastructure.

Furthermore, the energy density threshold of power batteries has been continuously increasing. In 2019, vehicles with an energy density of less than 125 Wh/kg cannot receive subsidies, and vehicles with an energy density of less than 160 Wh/kg cannot receive full subsidies.

Overall, the subsidy decline this time far exceeds 50%. What does such a significant subsidy decline mean for new players in the automotive industry?

New Forces in Car Manufacturing Facing Challenges

The biggest impact of the subsidy decline must be on the automakers. But automakers can be divided into two categories: new forces in car manufacturing and traditional automakers.

- New Forces in Car Manufacturing:

New forces in car manufacturing can be further divided into two groups. The first group includes NIO, XPENG, and WM Motors, which have already produced and delivered a certain number of vehicles. The second group includes Aiways, Horizon, BYTON, and other brands still in the process of vehicle production.

The players in the second group will be hit the hardest, especially those who have invested heavily in technology research and development, qualification acquisition, and construction of their own factories.

“`

“`

The subsidy is drastically reduced and their products will not start mass production until Q4, so they will barely benefit from the new energy vehicle subsidy. However, the cost of power batteries has not reached an ideal level, so the price of pure electric vehicles will definitely be slightly higher than that of the same level of fuel vehicles. As for the extra cost, should car companies choose to bear it themselves or accept lower sales and let consumers bear it?

Regardless of which option is chosen, companies will find it difficult to be profitable in the early stage. Even if they finally achieve mass production of their products, the process is far from over. Making cars is an industry that requires long-term investment of a large amount of funds. Founders of NIO, WM Motor and XPeng Motors have all stated that it costs at least 20 billion yuan to make cars.

At present, NIO has raised more than 27 billion yuan, WM Motor has raised over 23 billion yuan in Series C financing, and XPeng Motors has a total funding of over 25 billion yuan after Series B+. Obviously, these three companies are aiming at 30 billion yuan. After losing the subsidy bonus, new forces in the auto industry will need to spend even more money from their own pockets. They have no other choice but to continue to invest heavily to progress and hope to see the future.

As for the top players, they all achieved their target of 10,000 vehicles before the subsidy policy in 2019 and generated revenue, which is a good start. However, the road ahead is not easy, especially for WM Motor and XPeng Motors. Both of their products are priced around CNY 200,000, and the subsidy accounts for 20% of the car price. The reduction of the subsidy will lead to a significant increase in car prices, which may make consumers give up their choice. Fortunately, WM Motor and XPeng Motors have stated that the EX5 and G3 will maintain their current subsidies, so their prices will not be affected by the subsidy policy. Nevertheless, car companies will find it difficult to maintain their gross profit margin in the short term.

- Traditional Car Companies:

Traditional car companies can also be divided into two categories: domestic brands and joint venture brands.

There are many domestic brands involved in the production of new energy vehicles, and many of them started producing new energy models from the beginning of the policy. After 5 years of development, they have accumulated rich technical experience, obtained good sales, and generated significant profits. Domestic brands have seized this policy trend and utilized it to develop their new energy vehicles, just like BYD. Therefore, domestic brand car companies have less financial pressure and will stay composed when the subsidy is reduced.

In contrast, joint venture brands have few forays into the pure electric field, so the subsidy reduction has no impact on them.

“`

The impact exists, although the main development products of joint venture brands are not pure electric vehicles, almost every joint venture brand has more or less some pure electric vehicle models. Although the parameters of these models are not outstanding and car manufacturers do not expect to rely on these models to make a lot of profit, producing and selling these models can help joint venture brand automakers gain valuable points.

With the decline of subsidies, the cost of each point for joint venture brands has also increased, so the impact is still there.

Although major foreign car giants have publicly stated that China is one of their most important markets, compared with independent brand automakers, there is still a certain gap in attention and sensitivity to policies.

- Battery Manufacturers:

Subsidy decline not only affects automakers, but also affects domestic battery manufacturers. In the early years, in order to support the domestic power battery manufacturers, the government set a policy that only new energy vehicles using domestic brand power batteries can get subsidies. Those who cannot get subsidies have no advantage in price, so everyone began to choose domestic power batteries.

In the past 5 years, the technology level of domestic power battery manufacturers has made a leap, especially Ningde Times. In addition to winning orders from many domestic car companies, Ningde Times has also received many large orders from foreign car companies, including Volkswagen and Mercedes-Benz.

Now the impact of subsidies on car prices is getting smaller and smaller. Many foreign power battery giants have turned their attention back to China’s new energy vehicle market. For automakers, the range of battery choices will become larger as subsidies decline. For powerful power battery manufacturers like Ningde Times, who hold large orders, the impact will not be too great, but for second-tier power battery manufacturers, the challenge has come.

Policies will ultimately guide, but the market is the real operator

It is not difficult to see that subsidy policies have been guiding new energy vehicle companies to produce and manufacture electric vehicles with comprehensive endurance. Earlier, the way to increase endurance was to increase battery capacity. However, there is limited space in the vehicle, and it is difficult for automakers to put more battery packs in limited space. Therefore, in 2017, the subsidy standard was revised to include the energy density of the battery pack as an indicator. The policy began to guide power battery manufacturers to develop higher-energy-density batteries, thereby increasing battery capacity and improving vehicle endurance.Byd abandoned the lithium iron phosphate battery, which had low energy density but cost advantage, and turned to the embrace of ternary lithium. Major battery manufacturers have also continuously developed high-energy density batteries. In 2017, 140 Wh/kg was an excellent level, and 160 Wh/kg was only considered excellent in 2018. This year, to achieve outstanding energy density, it needs to be up to 180 Wh/kg. (The issue of battery safety after increasing energy density will not be discussed here. Interested friends can read this article: “Tesla’s ‘New Challenges’ under the shadow of spontaneous combustion.” (http://mp.weixin.qq.com/s? biz=MjM5NTIyMjA2MQ==&mid=2656750743&idx=1&sn=09837e4ceed36b239b7682edb8599a7c&chksm=bd55abd58a2222c3c2d9b460952f4dd0d81654d64baf0cf8126a77254e8e1c256d6086758e6e&scene=21#wechat_redirect))

The market and development path of new energy vehicles have gradually been established.

Under the protection of the invisible hand of the national subsidy policy, the new energy-related industries have grown for nearly 10 years without worries. As they gradually establish themselves, the invisible hand gradually loosens its grip. Although the constraints are getting less and less, they will have to bear it if there are any storms.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.

*

*