How powerful is the 150 kW fast charging for Audi e-tron?

In 2019, Audi e-tron and Porsche Taycan constantly make headlines, breaking the monopoly of Tesla. We’ve talked about Taycan several times, but have yet to delve into e-tron. Today, we’ll emphasize on the e-tron battery.

Why talk about the battery? Firstly, e-tron adopts a relatively uncommon route, the “soft package.” Secondly, the impressive battery performance and production issues of e-tron that have been unveiled so far are directly related to the soft package route.

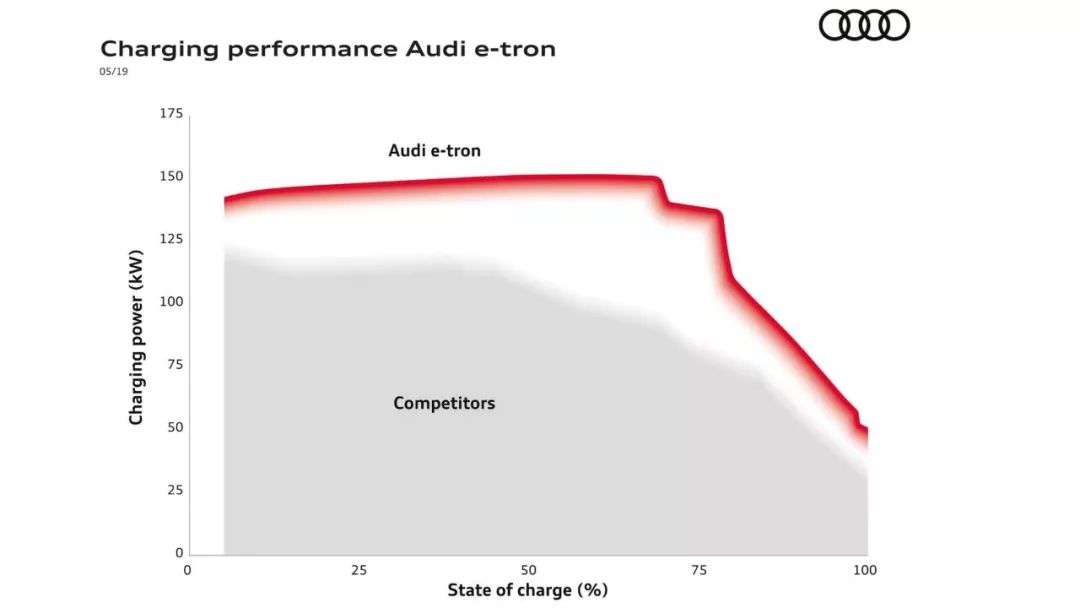

e-tron supports 150 kW DC fast charging, which can accomplish 0-80% charging in 30 minutes. This is the official charging curve given by Audi:

The horizontal axis represents the battery capacity, and the vertical axis represents the charging power. All competitors’ lines are below the e-tron. That means, given the same charging time, the e-tron charges more; for batteries of the same specifications, the e-tron charges faster.

Furthermore, we can see that when the battery reaches 75%, e-tron’s charging power remains above 125 kW, and when it’s at 100%, there is still around 50 kW of charging power.

German electric car media, next move, conducted a 0-100% charging and discharging test for e-tron, and we can see that the initial charging power of e-tron has peaked above 125 kW. It took 32 minutes to charge 80%, and 47 minutes to charge 100%, while the charging power remained high at 50 kW.

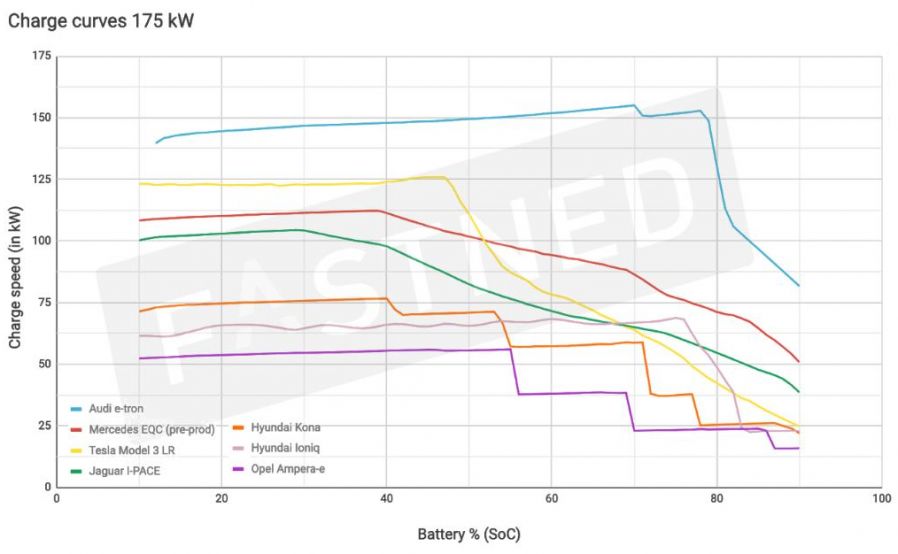

If we compare this with other competitors, third-party charging operator Fastned conducted a charging test for electric vehicles using a 175 kW DC fast charging pile.

From this graph, we can see that e-tron’s initial charging exceeded 135 kW, reached above 150 kW when the battery level was over 60% and started to decrease near 80%, but compared to all competitors including Model 3, charging power starts to decrease at less than 50%.

Of course, Tesla is an exception, and the focus of Model 3’s charging adaptation and optimization is always on its own Supercharger network.

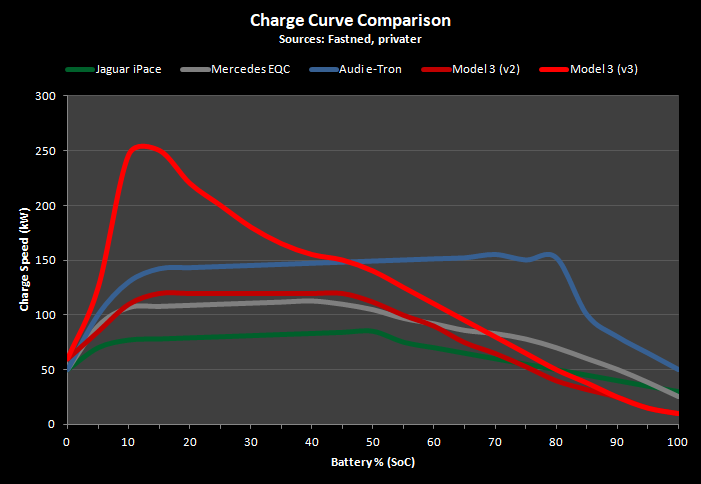

The following data includes the charging curves of Model 3 under the second and third generation Superchargers. If it is the latest 250 kW third-generation Supercharger, Model 3 is superior to e-tron in the first half of 0-50%, but the power drop in the latter half is faster than e-tron. However, if it is the second-generation Supercharger, e-tron is basically leading throughout the process.

Based on a large number of practical test data, we extract the key information:

-

47 minutes to charge from 0-100%, the fastest in the industry.

-

Even when fully charged, it can still reach 50 kW, the fastest “trickle charging” speed in the industry.

-

0-80% is basically stable around 150 kW, the only one in the industry.

In fact, the first and second items can be combined to discuss. Based on the chemical properties of battery materials, the charging speed of batteries will decrease as the battery level rises. Therefore, the charging time for most electric vehicles from 0-80% and 80%-100% is comparable. That is also why Tesla’s official website does not recommend using Superchargers to charge above 80% for long-distance travel.

However, the e-tron only takes 47 minutes to charge from 0-100%, and still has a power of 50 kW at 100%. As can be seen from the previous chart, most electric vehicles have a power close to or below 50 kW at 80%. What is this black technology?

A critical design is that the e-tron’s total capacity of 95 kWh restricts the available capacity to 83.6 kWh. Its 0-100% charging curve is not 0-95 kWh, but 0-84 kWh. This ensures that there is still a relatively fast charging speed when approaching 100%.

Some people may say, what’s so advanced about this?First, it is an industry-wide practice that available capacity is less than rated capacity, such as the Model 3 Long Range version with a rated capacity of 80.5 kWh, but only 75 kWh is available. Second, a simple calculation shows that filling up to 84 kWh is approximately 88% of the total battery capacity of 95 kWh. If you look at the competitors, they can achieve 50 kW power at around 90%, which is almost non-existent.

So, what is the advanced technology behind the e-tron battery pack?

What makes the soft pack line great?

As previously mentioned, the e-tron battery pack uses the soft pack line. So before we discuss the e-tron battery pack, let’s first talk about why the e-tron chooses the soft pack line.

First, it has a higher energy density. The soft pack battery is arranged in a stacked format of the cell and the heat sink. This arrangement allows for more efficient utilization of the limited space inside the car. Compared to the steel and aluminum housings of the square and cylindrical battery, the aluminum-plastic film packaging structure of the soft pack battery is significantly lighter. Whether it is specific energy or volumetric energy density, the soft pack battery has exhibited excellent performance.

For example, the General Motors Chevrolet Bolt, which also uses the soft pack line, is set up with a 60 kWh battery pack under a wheelbase of 2,601 mm.

Second, it has good electrochemical structure and long cycle life. In terms of structure, the soft pack battery has a lower internal resistance, which greatly reduces the battery’s energy consumption. At the same time, the soft pack battery has a higher cycle life than the cylindrical battery.

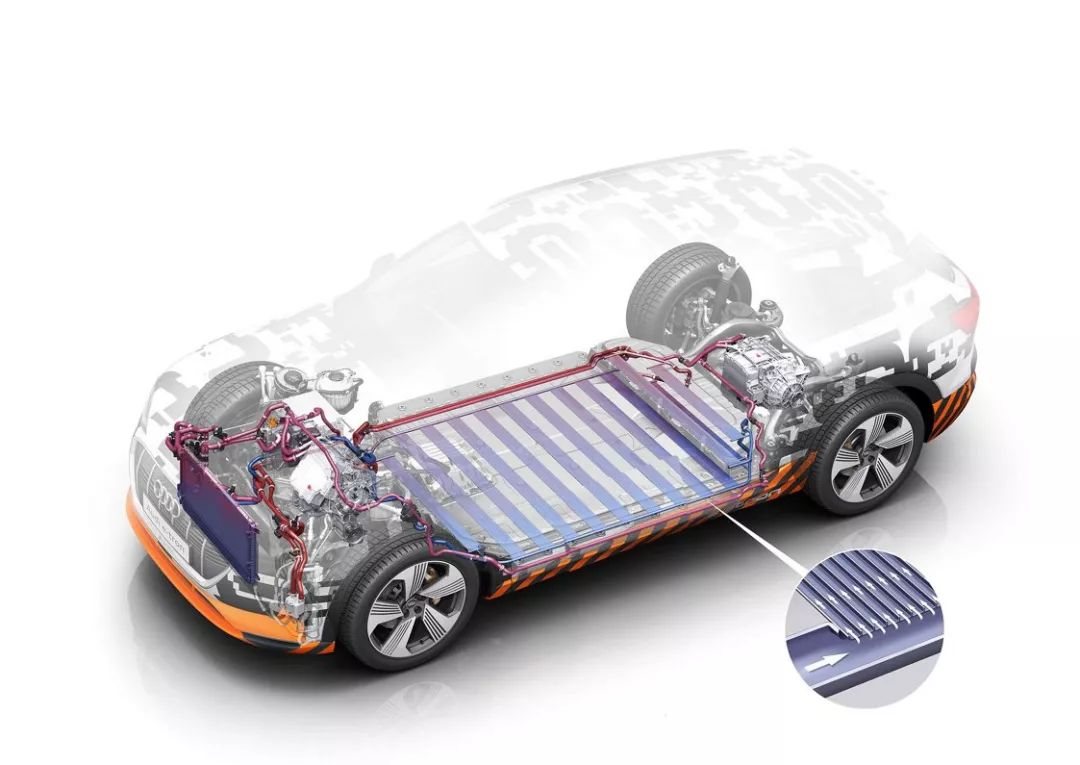

Finally, it is non-standardized and flexible in design. The size and specifications of the soft pack battery can be customized according to the needs of different OEMs, and develop new battery types for mass production. Below is the battery pack layout of the e-tron. You can see that the entire pack has an irregular shape with five modules arranged under the rear seats, stacked in two layers. These are LG Chem’s specifications customized for Audi.

After saying so much, does the soft pack line have no disadvantages? Of course, it does. For example, automated production of custom-made cells with non-standardized specifications has low automation rates, and stability and consistency are poor. In fact, the disadvantages of the soft pack line are fully demonstrated in the e-tron vehicle. Let’s discuss it in detail with the specific design.

Details of the e-tron battery pack

The e-tron is developed based on the Audi MLB modular longitudinal platform, and the battery pack design requires three things: specifications, durability, and safety.The e-tron is equipped with soft-pack battery cells from LG Chem, with a battery pack specification of 95 kWh and usable capacity of 83.6 kWh. The entire pack consists of 36 modules, with 5 of them located under the rear seats. Each module consists of 12 pouch-style lithium battery cells. In total, the pack holds 432 cells. The e-tron battery pack and electrical system operate at a voltage of 396 V. Everything from the modules to the pack, except for the cells, is independently designed and developed by Audi.

Below is the internal design of a single e-tron module, with a compact arrangement of the cells. Combined with the high energy density of soft-pack cells that we mentioned earlier, the e-tron should have a very competitive energy density. However, its actual pack weight is 715 kg, resulting in an energy density of 133 Wh/kg, which is not superior to certain parameters of Tesla and domestically manufactured electric vehicles.

In other words, although soft-pack cell structures and theoretical grouping efficiency are very high, Audi did not strive to maximize the energy density of the pack due to certain considerations. Below are some design details of the pack structure.

On the upper left is the battery junction box, followed by the upper layer of the aluminum housing of the battery pack, and then 31 modules arranged side by side. The black square box in the corner is the battery management control unit.

On the upper right is the aluminum impact structure, followed by the lower layer of the battery pack’s aluminum housing, and then the battery pack’s external aluminum frame. Below that is a liquid cooling system with dense piping layout, consisting of 40 meters of cooling pipes and a fill of 22 liters of coolant. Finally, there is a bottom protection plate to prevent the battery pack from being damaged by rocks and sharp objects.

The battery pack and all key parameters, such as charging status, power output, and thermal management, are managed by an external battery management controller (BMC). The BMC is located in the front luggage compartment on the A-pillar of the e-tron’s right side.BMC communicates with both motor controller and battery module controller (CMC), each controller monitors the current, voltage, and temperature of the module. The Battery Junction Box (BJB) is encapsulated in a die-cast aluminum casing and located at the front of the battery system, which integrates high-voltage relays and fuses, serving as the vehicle’s electrical interface. The data exchange between BMC, CMC, and BJB is carried out via a separate bus system.

Overall, the e-tron battery pack prioritizes heat dissipation and safety. Paul Schneider, the technical director of the e-tron project, explains that choosing a soft pack battery instead of a cylindrical or square one is because soft packs are easier to manage heat-wise. However, the e-tron’s heat management system is not simple by any means.

First of all, implementing a basic stable input of 0-80% at the 150kW level is a significant challenge for the battery’s thermal management system. Secondly, because the soft pack battery’s consistency is rather poor (one soft pack is equivalent to 4-5 cylindrical cells), controlling heat runaway is incredibly vital. Any slight deformation to the soft pack battery can result in a disaster.

Therefore, it is vital to securely control the battery pack in a safe temperature and volume range through a well-designed heat management system.

How did Audi do it? The e-tron battery module got rid of the conventional design of liquid cooling pipes intercrossing between the battery modules. All modules were compactly arranged together, and the entire liquid cooling pipeline was fixed under the module via thermal adhesive. Thermal conductive gel was then injected between the modules as a buffer. When heat is produced, the thermal conductive gel would uniformly transfer the heat to the liquid cooling system, ensuring that the entire pack’s temperature is within the safe range.

You may be questioning whether this design increases the heat dissipation efficiency. On the contrary, doesn’t the compact modules increase the risk of heat runaway?

Please note the aluminum alloy crash structure mentioned earlier. After moving the cooling pipeline to beneath the modules, the extra space that was not filled up by the modules was occupied by extravagant aluminum alloy frames. When a collision occurs, the aluminum alloy frame will crush and absorb energy, ensuring that the deformation only affects a minimal number of modules, thereby reducing the risk of heat runaway.

This design is indeed killing three birds with one stone.First of all, the shortcomings of soft pack batteries have been avoided by physically isolating each module using aluminum alloy, thermal conductive gel, and a liquid cooling system. This significantly reduces the low consistency and potential safety hazards of soft pack batteries after use.

Secondly, in theory, safety has been improved. Another benefit of the physical isolation is that it can theoretically reduce the probability of thermal runaway when the battery pack experiences unexpected deformation. Although it has not been verified in practice, the e-tron’s safety protection is well-designed.

Thirdly, an efficient thermal management system is the foundation of fast charging. Thermal conductive gel and dense liquid cooling pipelines control the temperature fluctuation of the e-tron battery pack within the optimal temperature range of 25-35 degrees Celsius, ensuring that 0-80% charging remains stable at around 150 kW.

Of course, this design also comes with some sacrifices. First of all, the advantage of high energy density of soft pack batteries no longer exists. After installing the bottom protective plate, the entire pack reaches 715 kg, and the energy density drops to around 133 Wh/kg, which is roughly comparable to the energy density of the 70 kWh version of the NIO ES8.

As we mentioned at the beginning of the article, “the impressive battery performance and production capacity issues exposed by the e-tron are directly related to the soft pack battery technology.” The performance is the 150 kW fast charging, but what about the production capacity? Faced with more than 20,000 backlogged orders, the e-tron manufacturing plant in Brussels has reduced its operating time to 6 hours/day and its workweek from 5 days to 4 days.

This is because LG Chem’s factory in Poland is also supplying batteries to Mercedes-Benz EQC, Jaguar I-PACE, and Audi e-tron. Due to the low automation rate of soft pack battery production and the imperfect technology of high-end aluminum-plastic films, the production capacity for large-scale production has presented significant challenges. Jaguar Land Rover CEO Ralf Speth previously publicly stated that the limit on I-PACE sales is not due to production capacity, but to how many batteries Jaguar can purchase.

Similarly, LG Chem’s insufficient battery production capacity directly limits the production capacity of the e-tron.

Finally, let’s summarize. When I saw the impressive fast charging and the battery pack mass of up to 715 kg, and the production capacity challenges of the e-tron, I immediately thought of a quote from Konstantinos Laskaris, Tesla’s chief motor designer.

“In vehicle design, the conflict between performance and constraints on performance always exists. These parameters are related to performance, energy consumption, body design, quality, and cost. All these indicators conflict with each other to some extent. Ideally, you want them to coexist, but considering cost constraints, compromises need to be made.”# Audi e-tron: A Classic Electric Vehicle Worth Praising

Audi has addressed the pain point of fast charging for its users, but has made sacrifices in terms of build quality and energy consumption. However, regardless of these shortcomings, the performance of the e-tron is still superior to that of most pure electric vehicles in the traditional camp. Therefore, we will continue to pay attention to Audi’s next pure electric vehicle.

42 Garage is recruiting 1-2 automotive interns as editors, located in Xuhui District, Shanghai. If interested, please send your resume and past works to d@42how.com.

Link to Audi e-tron: A Classic Electric Vehicle Worth Praising

Link to Tesla’s Handsome Challenger: Audi e-tron GT

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.