On October 15th, 2018, Tesla CEO Elon Musk retweeted a tweet from Tesla’s official Twitter account, which stated that the design and validation of the Model 3’s drive system had surpassed one million miles (1.6 million kilometers) – this is what the gear looks like after 1.6 million kilometers of testing. Elon’s retweet comment was: “The Model 3’s motor and gearbox are still in good condition after running for 1 million miles, designed specifically for high endurance.”

This is a microcosm of Tesla’s continued investment in the three electric fields of pure electric vehicles.

Tesla Motor’s Past

Before Tesla, most electric vehicles in the world used various specifications of permanent magnet motors, which made Tesla’s induction motor particularly attractive in the Model S/X. Many analysts believe that Tesla chose the induction motor because its structure has higher strength and performs better in high-speed scenarios, and the lack of permanent magnet materials also makes manufacturing costs relatively lower.

Of course, this is one of the considerations, but the main reason is that Tesla developed the induction motor by inheriting the technical route from AC Propulsion.

AC Propulsion is a company that cannot be bypassed when it comes to writing the history of electric vehicles in the United States. The company was co-founded by Alan Cocconi, Wally Rippel, and Paul Carosa in 1992. Alan is a very important expert who designed and manufactured the electric motor and control system of the GM Impact, which is the prototype of the famous General Motors EV1. In other words, Alan was deeply involved in the development of the EV1.

AC Propulsion is committed to producing high-performance, long-range, and high-efficiency induction motor drive systems. Does that sound familiar? The “high-performance, long-range, and high-efficiency” here is exactly the same as Tesla’s goal in building the Roadster. Tesla acquired AC Propulsion’s induction motor and electric drive system design and charging patent license. AC Propulsion co-founder Wally Rippel also joined Tesla as the chief power electronics engineer.Is it true that the core technology of Tesla Roadster is “reverse engineering”?

In fact, after Wally Rippel joined Tesla, due to the huge difference in product positioning between Roadster and EV1, Tesla had to redesign the induction motor powertrain comprehensively. According to Marc Tarpenning, “many things have fundamentally changed in terms of materials and technology” when comparing the induction motor with the initial engineering test prototype one year before Roadster went into production.

To sum up, from the establishment of the entire vehicle engineering and three-electric research and development team by Wally Rippel in 2006 to the start of Model S production in 2012, Tesla was in a rapid iteration and learn-by-doing phase. This was the first stage of Tesla’s three-electric development.

In 2012, Konstantinos Laskaris joined Tesla. Like Tesla CTO, JB Straubel, he is also a man who firmly believes that electrification will sweep across all industries from an early age, and has devoted his life to it. At that time, Tesla’s Model S electric drive system R&D testing had come to an end, and the pre-research of Model 3 electric drive system was about to begin.

Laskaris’ task was to continue the technology accumulation of induction motor route, and to constantly explore the balance between performance and efficiency. On the other hand, he had to reset the team completely and start the research and development of next-generation motor technology.

Today, it seems that Laskaris has done an excellent job in connecting the past and the future of the work. 16 different models of power performance, including Model S/X 40/60/60D/70/70D/75/75D/85/P85/P85+/85D/P85D/90D/P90D/100D/P100D, were achieved by only using three types of induction motors.

At Tesla’s Fremont factory, Tesla completely designed, developed, and manufactured motors from scratch (Model 3 motors are produced at Gigafactory 1 in Nevada). Therefore, Tesla can optimize every detail of motor manufacturing and control product quality. According to Laskaris, the motor team will simulate the testing process through mathematical modeling and computer clusters, and then implement improvements very quickly in production.

As Laskaris mentioned in the interview, mathematical modeling techniques have a huge impact on the success of electric vehicles. Here, “modeling” refers to understanding the mathematical principles behind the system, and then creating software tools to accurately simulate its operation in the real world.

As Laskaris mentioned in the interview, mathematical modeling techniques have a huge impact on the success of electric vehicles. Here, “modeling” refers to understanding the mathematical principles behind the system, and then creating software tools to accurately simulate its operation in the real world.

On the other hand, this means that the Tesla Motor team needs strong software programming skills to implement power constraints or adjustments, and the discharge output and energy consumption control of high-performance models in rapid acceleration and extreme operating conditions are also very critical.

During Laskaris’ academic career, he received a bachelor, master, and doctoral degree in electrical and computer engineering, communication and signal processing, motor and gearbox design, and geometric optimization fields, with a very profound and interdisciplinary theoretical background in motor design. In addition to his job, he believes that motor engineers should also understand software engineering and be able to write code.

“If you know how to turn your ideas as an engineer into code, you will do well. Once you start having your own imagination and ideas, this will be a huge advantage. I would say that having some programming skills is absolutely crucial.”

The permanent magnet motor on Model 3 is the latest work of Laskaris’ team, with a new motor, a new technological route, and a new record of energy efficiency and performance products. Tesla has invested heavily in it. In addition to Model 3, Model Y, the new Model S/X, and Tesla Semi Truck also use this motor, which means that there is a significant research and development investment amortization and economy of scale effect on the product matrix level, resulting in cost reduction.

Furthermore, the impressive comprehensive input-output ratio is also one of the aspects that Laskaris considers. Laskaris mentioned in the interview that in some cases, manufacturing a high-efficiency motor at a higher cost can save more costs in battery packs or other aspects of car manufacturing. Therefore, if you can accurately simulate motor efficiency and cost, you can directly compare the incremental manufacturing cost with the cost savings from the battery.

In fact, the best motor for minimizing comprehensive costs is often different from the cheapest motor.

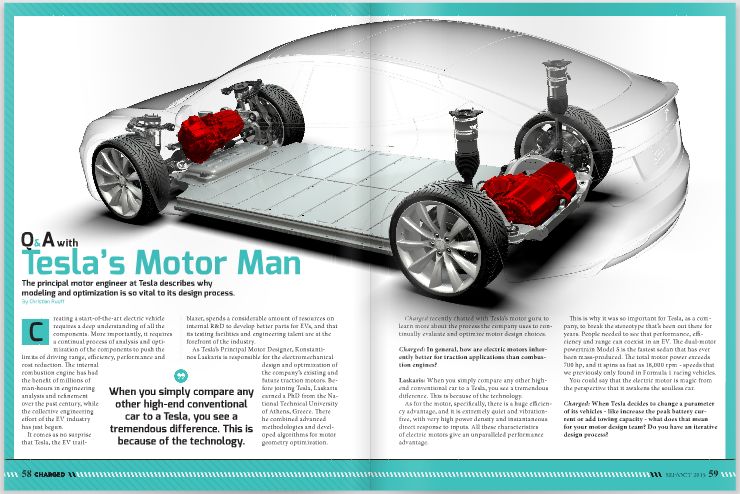

To build an advanced electric vehicle, it is necessary to have a deep understanding of all components. More importantly, this requires continuous analysis and optimization of components to push the limit of the balance between range, performance, efficiency, and cost. In the past century, incremental technological advances in engineering analysis and improvement have been made in gasoline powertrains for millions of working hours, while the collective engineering efforts of the electric vehicle industry have just begun.Over the past decade, Tesla has invested heavily in the development of better electric powertrain components, including talented personnel for designing and testing components as well as state-of-the-art equipment.

After working at Tesla for seven years, the handsome young man Laskaris has also become a middle-aged man. We look forward to Laskaris’ team bringing the next surprise to the electric vehicle market consumers.

CHARGED has interviewed Laskaris twice. Through these interviews, we gained a deeper understanding of Tesla’s strategy and perspective on the electric powertrain industry. We decided to share the interview with you. Enjoy.

Q: Are electric motors better suited to drive cars than traditional engines?

A: Simply comparing any other traditional luxury car to Tesla, you will find a huge difference, and that is because of the electric motor.

Specifically, electric motors have huge efficiency advantages, they are very quiet and vibration-free, and have very high power density and instantaneous response to torque. All of these characteristics contribute to the unparalleled performance advantages of electric vehicles.

This is why the electric motor is so important to Tesla, breaking long-standing stereotypes of electric vehicles. Consumers have discovered that performance, efficiency, and range can coexist in EVs. The Model S Performance is the fastest accelerating production sedan to date, with total power exceeding 700 horsepower and a maximum RPM of 18,000, a parameter typically seen only in Formula 1 racing.

You could say the electric motor is a mystical presence.

Q: What does it mean for your motor design team when Tesla decides to increase peak current output or peak motor power? Do you have an iterative design process?

A: At the Tesla Fremont factory, we manufacture virtually all of our own car components. We have motor winding and manufacturing lines, so we can optimize every detail of motor manufacturing and control the quality of our products. Additionally, we can make improvements in production very quickly, making us a highly agile company.

We can quickly generate the geometric structure of the motor and analyze it through finite element analysis. We have a large computer cluster with over 500 processor cores to perform finite element analysis. –– A PC has two or four cores. This means that we can parallelize the creation of many virtual models and perform a large number of calculations. It allows us to solve the balance between loss and efficiency quickly and see how well any motor design matches the application we are designing based on any metric we create.

Q: The topology, architecture, and configuration of motors seem to have endless options. How do you start evaluating and comparing all possible motor options?

A: Understanding exactly what you want a motor to do accurately is the primary task of optimization. You need to know the exact constraints – exactly what you are optimizing for. Once that is understood, you can use advanced computer models to evaluate all motor options with the same goals. This will give you an understanding of the performance of each motor technology. Then you go pick the best one.

Often, in vehicle design, there is always a conflict between performance and performance constraints. These parameters are related to performance, energy consumption, body design, quality, and cost. All of these metrics conflict to some extent. Ideally, you want them to coexist, but some compromises need to be made considering cost constraints. Electric vehicles have additional challenges because energy efficiency is a critical consideration.

Every company has a different view on what trade-offs should be made. For example, how much range are you willing to sacrifice for faster acceleration? Once these parameters are set, you can start evaluating options and optimizing.

Q: You have a background in algorithm development. How do these algorithms allow computers to simulate how motors operate in the real world and how does this drive the creation of better vehicles?

A: The mathematical modeling techniques or methods you use are critical to the success of electric vehicles. When I say “modeling,” I mean understanding the mathematical principles behind the system and then creating software tools to accurately simulate its operation in the real world.

Accurate motor modeling is essential, and through it, we can evaluate a hypothetical motor before production – loss, performance, torque fluctuation, thermal management, and any metric we are interested in to confirm whether the simulated motor is good or bad. This way, we avoid unnecessary prototypes and unpleasant surprises.

In addition, with good motor modeling, we can achieve the best optimization. We can achieve amazing performance without using special materials and challenging manufacturing methods.Optimization is an art that allows understanding of different candidate motors, what is good, what is bad, and how good or bad they are. When you start optimizing, you realize that optimization is meaningless without good modeling. This is because the entire optimization process will be based on incorrect motor performance and the optimized motor will not be the one with the best actual performance.

Q: Can you provide some examples of using modeling to balance optimization?

A: Sure. Most of the time people drive on highways with low torque demands. There are many motors that can provide ultimate zero-to-sixty acceleration, but their efficiency is very low under the low torque demands of highway conditions. So the problem is, can you have both high efficiency and high performance? Unfortunately, the answer is no. But you can make wise trade-offs between conflicting indicators.

This is the beauty of optimization. You can choose from all available options to get the best motor with the given constraints. If we have done the proper modeling, you can find the motor that has both high performance in zero-to-sixty and high efficiency on highways.

Another example is balancing the efficiency of the vehicle as a whole with the cost of the motor. In some cases, manufacturing a highly efficient motor at a higher cost can save more costs in other aspects of battery or car manufacturing. So if you can accurately model motor efficiency and cost, you can directly compare the incremental manufacturing cost with the battery cost savings. In fact, the best motor for minimizing total cost and the cheapest motor are often different.

All of these come together to form the performance metrics you want to build for your car. This is the general approach we take from parameter design to final configuration.

Q: When do we conduct physical prototype testing to verify virtual modeling results?

A: Before we have a prototype specific to a particular application, we conduct multiple rounds of validation testing. We call them characterization experiments. They allow us to obtain known reference points and see if the isolated modeling tools are in sync with reality. So it is a back-to-back comparison between simulation prediction and actual testing. It may not even be a motor, it could be just a rotor.

Then we build and test a complete prototype motor.

Q: Can you talk about the trend in electric vehicle costs?

A: When it comes to permanent magnet motors, the fluctuation of magnet prices in the past has been too great to represent a general discussion on motor costs.

However, the more we optimize, the lower the motor cost, and as the power density of the motor increases, the motor becomes smaller. If you don’t use a motor with miniaturization and higher power density, the motor cost will gradually decrease. Other than magnets, the material prices in the motor are stable.Therefore, we see a trend that due to the technological improvements we have made over the years, motors are gradually becoming cheaper. There are also better manufacturing methods, and we are reducing manufacturing costs. If we had tried to manufacture the motors we use now 20 years ago, the cost would obviously have been much higher. There are many types of technology that will come into play here, making motors cheaper.

It is an evolution combining material technology and design technology. For example, achieving higher slot fill on the winding will effectively make the electric motor smaller and cheaper. Using thinner steel can allow the motor to achieve higher frequencies, making it smaller and cheaper.

Understanding the electric drive system as a whole system is a very important thing and will also reduce costs. And it’s not just about cost, it will become a better product because of the rich design experience and more advanced simulation techniques that allow you to optimize the operating conditions you want, or quickly understand the system and design systems that take full advantage of material performance without being over-designed.

Optimization is an important part of making economical cars, which can also have amazing performance and range as well as all the necessary specifications.

Q: Where do you think the potential in the optimization field lies? Does it depend on software?

A: It is a combination of software functionalities. For example, modeling the motor precisely and simulating the motor you don’t want to manufacture through more advanced modeling tools, so that you don’t make design errors. Then understand what you want to optimize. This comes from experience, how do cars drive? What do users want? All of this helps to understand what kind of motor we should design and finally simulate to present the motor that we have finally designed.

Q: Is there such thing as black technology in motor design? Similar to the discussion of lithium-air battery technology (low cost, long life, high energy density)?

A: The improvement of motors depends on motor technology and motor materials, which will determine the ultimate traction motor. In terms of materials, the core of what I want to say is plastic – non-conductive and with huge magnetic permeability, which can be excited by very low current. (Maybe) this is impossible to commercialize, but we are trying to move in this direction. The materials we can use now have conductivity limitations. Therefore, these materials will allow us to obtain better performance, and from the material’s point of view, we know where the ideal position is.

However, from a design perspective, I want to say that I can give an example, but don’t get too caught up in it. For example, a synchronized separately excited machine with full flux regulation capability is like an ideal control motor and performance motor. But it has great manufacturing challenges.

Therefore, motor designers create all kinds of motors for manufacturability and feasibility, but there are also some motors that make no compromises but are difficult to manufacture. That’s why you see so many motors.Q: The working principle of the induction motor is like nature’s gift – as its way of generating eddy currents beautifully twists the magnetic field and produces torque unlike any other. You have no brushes or conductors, and the motor has excellent characteristics. It has been around for over a century and has hardly changed. Of course, our use of it has greatly changed with the advent of computers. This is a steadier motor. This is a motor with high torque density.

A: Reducing copper losses in windings is something almost everyone is striving for. It is so dominant and obvious that if we can achieve a conductivity greater than that of copper, it will be groundbreaking and significant not just for Tesla but for everyone involved in manufacturing motors. If it happens, we will know about it soon enough and it will be adopted. But so far, there are very few materials that can do it. Silver is the most conductive material you can find, but it is much more expensive than copper. That is why copper dominates in most cases. But I’d love to see evolution there.

I see some companies working on this, but at the same time they are also working on improving their mechanical properties. I have not seen anything directly commercializable in the foreseeable future.

Q: Electrical steel with 6.5% silicon added has been shown to reduce core losses without sacrificing saturation magnetization. What do you think of silicon steel manufacturing?

A: Gradually lowering the losses in the steel allows you to change the design considerations, go to higher frequencies, and make the motor smaller. For example, if you have an eight-pole machine of a certain frequency, if you have low-loss steel, you can choose a ten-pole machine, and then you gain more torque density. So, you can trade off iron loss for torque density. That is, you can make all these design adjustments across the board and redesign the motor to ultimately offer a better product.

Some companies have high silicon content (in their motors), but it requires a lot of energy and it’s hard to bring down the cost because energy has a given cost. But we will keep an eye on it and we are very interested in technological evolution.

Q: The breakthrough in high-temperature superconductors makes it possible to reduce rotor resistive losses and increase magnetic flux density. What do you think of superconductive wire manufacturing?

A: There is still a long way to go for the automotive industry because the cooling costs have to outweigh the efficiency or compression benefits. So, at least for now, the traction application of electric vehicles may not be the right scenario for it. It would be more suitable for applications that require higher continuous power density.

Q: What is your opinion on the current state of low-loss and high-speed bearing technology?A: Increasing speed is one of the two ways to improve power density. One is torque density and the other is speed. High speed is limited by factors such as mechanical structure, bearings and gears. Therefore, bearings are sometimes one of the limiting factors for the highest speed we want. Obtaining low-cost bearings that can withstand higher speeds is absolutely what we expect, especially for traction applications.

If you look at the bearing manufacturer’s catalog, you will find bearings that can withstand high speed and high efficiency, but they are expensive, so they are trying to reduce costs. We are happy to see the results and evaluate whether some better bearings are attractive drive unit solutions.

Q: What is your opinion on using soft magnetic materials to manufacture motor cores – for example, amorphous, nanocrystalline, and soft magnetic composite (SMC)?

A: Amorphous provides a very good balance between saturation and loss, but there are limitations in manufacturing. We have not yet seen widely used commercial motors although I know some companies have made prototypes with amorphous steel.

Silicon steel is currently a very good material, also between loss and saturation. This may be the direction for radial magnetic machines.

When there is a three-dimensional magnetic field change in the magnetic core, SMC allows the magnetic field change to reduce iron loss, for example, when you use a transverse magnetic machine or axial magnetic machine. Similarly, there may be a better balance between saturation and iron loss. So I think the development of silicon steel is what the automotive industry expects.

Q: What is your opinion on new technology to reduce active torque ripple?

A: I prefer to optimize the geometric structure to avoid torque ripple from the beginning, rather than trying to alleviate torque ripple through control. I think you can do a lot to optimize the geometric structure without generating torque ripple. This is something that can be easily captured with finite elements. If you need to actively reduce it, you will be subject to bandwidth constraints, as the frequency will increase. So I think torque ripple should be addressed through hardware adjustments.

Q: There is a lot of discussion about the switched reluctance motor (SRM) as a possible next-generation electric vehicle traction motor. What do you think of SRM?

A: SRM is a very special machine. Its manufacturing is very simple, but it is difficult to control. It has some challenges with noise and vibration. By design, you can make it better, and you can control it by mitigating all of these issues.The torque density is not bad, but establishing constant power is a challenge, and constant power is required in traction applications. So, once again, I always hope to see new ideas, and because it is a very simple rotor structure, it is really attractive. It may be applicable to solve this class of problems.

Q: For young engineers who want to make an impact on the electric vehicle industry, what specific areas of technology do you think they should focus on? What do you think is the most influential technical challenge?

A: I would say first of all, do not underestimate classical science – a good mathematical background, a good physical background. This is always a trend. You will always benefit from your understanding. If you learn how to use commercial tools for design, you will be prepared for this industry, but having a good theoretical background is much better.

Secondly, motor control is a subject with broad prospects. But I would say that in order to design good motor control in the future, you also need to have a good understanding of motors. Some people want to do motor control before they start studying motors, which is not recommended.

Energy storage systems are also exciting. This is a field with a lot of research opportunities.

Of course, software engineering and writing code. If you know how to turn your ideas as an engineer into code, you will do well. Once you start having your own imagination and ideas, this will be a huge advantage. I would say that having some programming skills is absolutely essential.

42 Garage is recruiting 1-2 automotive editorial interns in Shanghai Xuhui District. If you are interested, please send your resume and past work to the email d@42how.com.

- Tesla’s Automated Driving Chip Mass Production: A Long-planned Attack* How is the battery of Tesla Model 3 made?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.