March 15, 2019, 11:00 AM PST, at the Tesla Design Center in Hawthorne, California, USA, Tesla CEO Elon Musk unveiled the new generation electric SUV: Tesla Model Y, to the world.

Model Y is the last piece of the Tesla SEXY product series puzzle and the latest masterpiece that collects cutting-edge technologies from safety, design, intelligence, three-electric systems, engineering, and manufacturing, over the 15 years since Tesla’s establishment.

After a heartfelt speech (for more than 30 minutes), Elon talked about all the product information about Model Y within five minutes. Will this be the most mediocre car model in Tesla’s history?

The first car to beat the Model 3; The SUV you have been waiting for.

The first car model to beat the Model 3; this is the SUV you have been waiting for: Model Y.

After a 20-minute delay, Elon finally appeared on the stage of the press conference. After mentioning the mission of “accelerating the world’s transition to sustainable energy,” Model Y made its debut.

As Model X is to Model S, Model Y is an intelligent electric SUV built on the same platform as Model 3, which means that it has many similarities with Model 3. These are the two most similar car models created by Tesla, which directly led to subtle changes in the style of today’s Tesla press conference.

- Design

Genuine Tesla Style. As Elon said before the press conference, “Being an SUV, Model Y is about 10% bigger than Model 3.”

The design elements that please the eye and are well-received in Model 3, such as the cute monster front headlights, panoramic sunroof that extends from the bottom of the front trunk, hidden door handles, and streamlined body decorated with concise lines, reappear in Model Y.

The interior design of Model 3, which features the innovative steering wheel roller and 15-inch touchscreen for all vehicle controls, as well as the design of the integrated and infinite variable air conditioning system without instrument panel, have all been retained.

The only difference is that with Model 3 paving the way, these once forward-looking designs no longer seem radical, leaving us with designs that combine both functionality and aesthetics.

- Safety

Safety has always been the top priority of the Tesla team. After Model 3 was awarded the lowest injury probability five-star safety rating by NHTSA, it is no surprise that Model Y, an SUV with the same platform as Model 3, will continue the tradition of the Tesla product family and achieve a five-star safety rating from NHTSA.

Model Y adopts a steel-aluminum hybrid body frame to increase the overall rigidity of the vehicle. The newly designed anti-collision beams and center pillars from Model 3 are passed down, along with the design from the earliest Model S where the battery pack is placed flat on the bottom of the chassis. This design allows Model Y to achieve high overall vehicle safety. The weight distribution of 48% front and 52% rear also lays the foundation for greatly improved handling performance.

- Powertrain

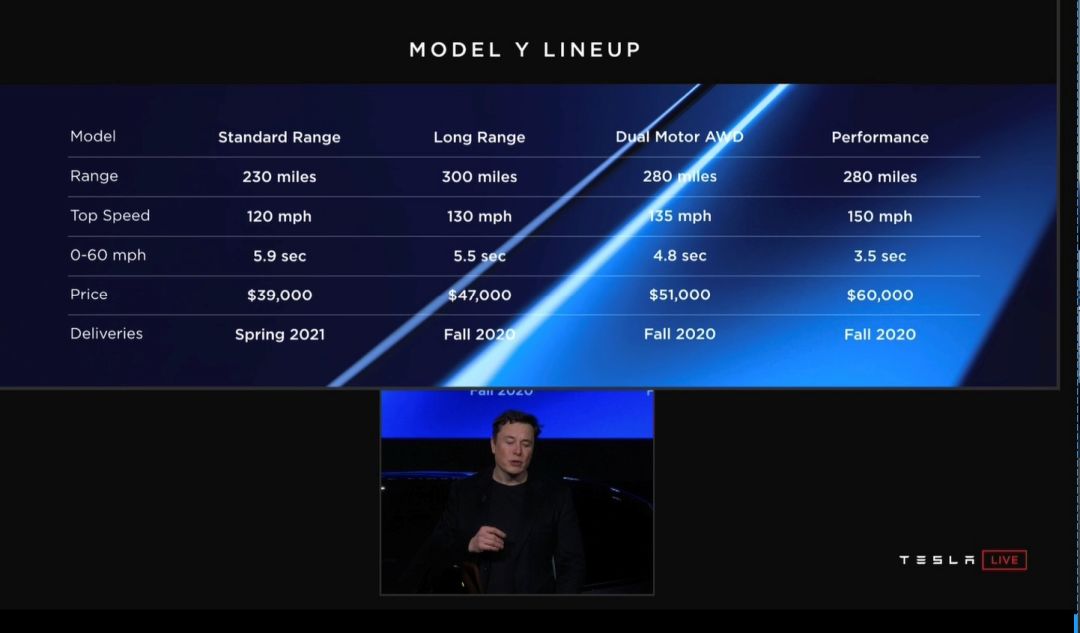

The Model Y Performance can accelerate from 0 to 100km/h in 3.5 seconds, with an EPA-rated range of 483 km. All thanks to the new generation of electric motors and the 2170 battery from the same platform as Model 3.

At the end of 2015, Elon tasked the Tesla motor design team to develop the next generation electric motor. According to Konstantinos Laskaris, Tesla’s chief motor designer, Elon’s requirements were: to develop a new motor that is cheaper, more efficient, more compact, and without compromising performance, compared to the induction motor used in Model S/X.Finally, the Tesla team designed the Permanent Magnet Switched Reluctance Motor, which was first commercialized in the Model 3. Sandy Munro, a well-known dismantling expert of Model 3, commented that the Tesla Permanent Magnet Switched Reluctance Motor combines the advantages of permanent magnet and induction motors, and cleverly avoids the shortcomings of both motors.

On June 18, 2017, Tesla began production of the 2170 battery based on the NCA 811 formula for the Model 3 at Gigafactory 1. As of today, Tesla and Panasonic’s investment in Gigafactory 1 has exceeded US$4.5 billion. The 2170 battery, which combines the highest energy density and lowest cost, together with Tesla’s new generation BMS, allows Model Y and Model 3 to support Tesla’s third-generation Supercharger with up to 250 kW, and only takes 15 minutes to charge from 0 to 80%.

- Autopilot

Autopilot was not mentioned at the conference, but it received the biggest update.

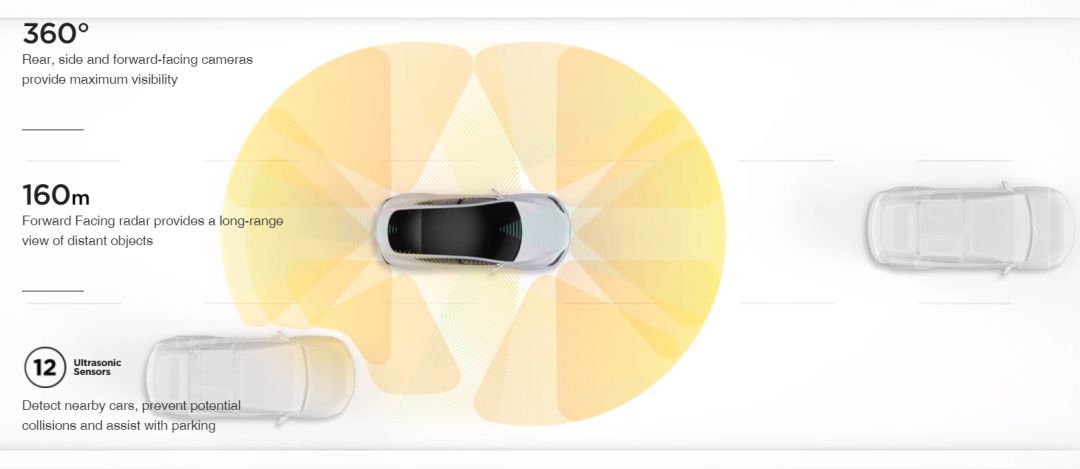

Model Y will be equipped with the new generation Autopilot 3.0 hardware, and the perception and computing capabilities of the vehicle may be updated. Cameras, radar, ultrasonic sensors, and computing platforms—all hardware targets are aimed at one goal: autonomous driving.

In October 2016, Tesla began production of its vehicles with Autopilot 2.0 hardware and launched the Tesla AI chip project aimed at autonomous driving. Elon subsequently stated on several occasions in public that all AP 2.0 vehicles would support autonomous driving, and even if the computing power was insufficient, autonomous driving could be easily achieved by replacing the chip.

Considering that the Tesla AI chip that drives the AP 3.0 hardware is designed according to the standard of autonomous driving, with redundancy and fault tolerance, we have reason to believe that Tesla will further enhance the performance of other sensor hardware to meet the standards for landing autonomous driving cars at the hardware level.

Model Y may be the world’s first mass-produced limited-scenario autonomous driving car.I know what you want to say- in the already crowded midsize SUV market, Tesla’s Model Y seemed to lack the scream-worthy features of their previous launches. Can we really imagine that, three years after releasing the Model 3, Tesla’s only achievement is a taller and wider Model 3?

The only thing that is changed is everything.

Model 3 and Model Y are the most closely related cars in Tesla’s history, and their affordable price position naturally draws potential owners who pay more attention to functionality. The higher comfort, stronger off-road capability, and larger space of an SUV model give Model Y a natural advantage over Model 3.

Even without any improvements, Model Y is still able to beat out Model 3.

Given that Model 3 has only recently met the needs of the domestic market, Tesla has only just begun deliveries in Asia-Pacific and Europe, it’s more reasonable for Tesla to downplay the propaganda of Model Y at this stage, rather than weaken the impact on Model 3.

This is the first safety, design, space, performance, and Autopilot-free press conference in Tesla history, with only one slide introducing basic parameters, one Model Y, and a darkened room.

After the end of the conference, two Model 3 preorder owners @ me and asked if they should still buy a Model Y. Tesla’s strategy succeeded.

The title of this section is “The only thing that is changed is everything”. Many people may be confused about where these “differences” are.

Firstly, there is a comprehensive improvement in engineering design errors.

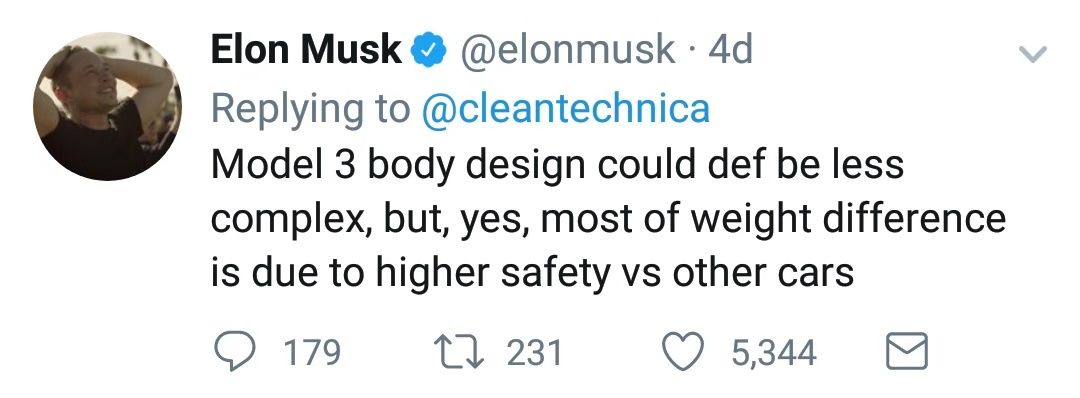

Elon has mentioned on Twitter that, in order to achieve the best safety, the Model 3 project team made a lot of excessive designs on the white body, and the complicated joints did not play a role. Instead, they increased the manufacturing cost and also raised the curb weight, which in turn affected other indicators such as cruising range and handling.

According to the teardown specialist Sandy, the design flaw of Model 3 is not persistent throughout the entire lifecycle. After simplifying the welding method and removing unnecessary parts, the problem can be thoroughly solved on Model Y.

According to the teardown specialist Sandy, the design flaw of Model 3 is not persistent throughout the entire lifecycle. After simplifying the welding method and removing unnecessary parts, the problem can be thoroughly solved on Model Y.

In terms of three electric areas, the greatest imagination comes from the improvement of battery technology. On February 5, Tesla announced the acquisition of Maxwell. 20 days before the acquisition, Maxwell informed investors that there was a high probability of achieving strategic partnerships within six months.

Considering Tesla’s consistent aggressive intervention in history and the project cycle of Model Y that will not be put into production until Q3 next year, the possibility of Maxwell technology commercialized on Model Y’s electric drive powertrain tends to be unlimited.

However, what if the integration with Maxwell encounters a setback? As we mentioned earlier, the 2170 battery was put into production in June 2017. In January 2018, Tesla upgraded the battery formula.

At the 2018 Tesla shareholder meeting, Tesla CTO JB Struabel mentioned that Tesla had already mastered the implementation approach of increasing battery energy density by 30%-40% in the next 2-3 years.

In November 2018, Tesla Automotive President Jerome Guillen mentioned in an interview with CNBC that the design of the 2170 battery had not been frozen, and Tesla had a promising technology improvement roadmap and would continue to improve in aspects of design, engineering, manufacturing, and electrochemistry.

With the continuous increase of battery energy density, the battery pack specifications of Model Y will exceed 75 kWh and reach 85 kWh, or even higher.

As you know, these technological advancements have been clearly explained at the shareholder meeting, but were not mentioned during today’s press conference. The reason is simple: Tesla’s highly efficient technological advancements in conflict with their low production capacity climb, forcing Tesla to prevent Asia Pacific and European Model 3 owners from receiving “outdated models upon delivery”, or even worse, “outdated models before delivery”.

As you know, these technological advancements have been clearly explained at the shareholder meeting, but were not mentioned during today’s press conference. The reason is simple: Tesla’s highly efficient technological advancements in conflict with their low production capacity climb, forcing Tesla to prevent Asia Pacific and European Model 3 owners from receiving “outdated models upon delivery”, or even worse, “outdated models before delivery”.

In the core competitive area of Tesla’s Autopilot, some hardware improvements are quietly happening. In August 2017, with the start of Model 3 production, the AP 2.5 hardware model was also produced.

The only enhanced millimeter-wave radar was replaced by Continental’s ARS4-B, providing a comprehensive enhancement in its scope, distance, precision, and quality over Bosch’s mid-range radar (MRR). In addition, the selection of the cameras has also been adjusted.

A greater innovation comes from the computing platform. The design of the Model 3, which integrates all information on a central touchscreen display by removing the instrument cluster, provides the underlying computing platform integration conditions. The computing platform of AP 2.5 is updated from the Parker+Pascal chips of AP 2.0 to dual Parker+Pascal chips. On the back of the autopilot circuit board, Tesla integrates an integrated system of the instrument/navigation board based on Intel chips and NXP MCU, while integrating the TBOX and GNSS receivers on the board.

AP 2.5, as the only computing platform in the industry that fully integrates autonomous driving and instrument entertainment, achieves an advanced level in both design and manufacturing.

What I want to say is that Tesla is always improving and upgrading, which makes us look forward to the fully redesigned Tesla’s next-generation computing platform, AP 3.0, or Model Y’s computing platform.

Finally, we need to mention the fully automatic production line again.

In the first half of 2018, Tesla suffered heavy losses due to the premature push for automatic production lines. In the second half of 2018, Tesla underwent comprehensive financial contraction due to financial reporting pressure.

We attempted to answer the unanswered questions from Elon’s press conference, and we can confirm that the Model Y’s ultra-high integration design, as low as 100 meter cable harnesses, has been canceled. The 76% reuse rate of components with the Model 3 greatly limits the operability of radical innovation.However, in January 2019, the fourth assembly line of Model 3 arrived at Tesla’s Fremont factory in California from a German automation plant, which had higher efficiency and lower cost thanks to the new production line and redesigned battery pack. This directly promoted the start of production of the Model 3 Standard (rather than just closing stores to save costs).

Led by Tesla CTO JB Struabel, Tesla’s automation factory team and Tesla’s three-electric team are advancing the commercialization of the world’s most advanced intelligent electric vehicle technology.

Tesla will always be Tesla, adhering to the first principles-centered product, extensive engineering and technological innovation, which is the essence of Tesla.

This is Model Y

Model Y, here

One highlight of this event is Tesla’s Shanghai factory. Yesterday, the first steel column of Tesla’s Shanghai super factory was successfully hoisted, and Elon mentioned China’s speed again at today’s event.

On December 4, 2018, Business Insider obtained a Model Y project document that revealed the design of a third-row seat, higher armrests, and instrument panels, all of which have now come true. The production plan for Model Y is as follows:

-

By June 1, 2020, the first Model Y trial production line will be established in Gigafactory 1 in Nevada, and production will begin on August 1. The production capacity will reach 2,000 vehicles/week by September 1 and 7,000 vehicles/week by December 20.

-

In October 2020, the first overseas Model Y trial production line will be established in Gigafactory 3 in Shanghai, and production will reach 2,000 vehicles/week by November/December. The production capacity will reach 5,000 vehicles/week by February 2021.

While the start of Model 3 production in China was two years later than the US, the planned start of Model Y production in China is only two months after the US.

Don’t be fooled by Elon Musk: Model Y is the most powerful intelligent electric SUV in its class. This message is for consumers and for all ambitious new car makers and traditional giants in the audience.

Model Y, here.“`markdown

“`

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.