Key Model Y

For Tesla, Model Y is crucial.

If you are an automaker and your annual sales reach 100,000, 1 million, or 10 million vehicles, your capacity, R&D competitiveness, and supply chain bargaining power are completely different.

From 2012 to 2017, Tesla’s sales of Model S and Model X reached a level of 100,000 vehicles per year. The addition of Model 3 in 2018 allowed Tesla’s annual sales to reach 300,000 vehicles. Despite this, Tesla’s product prices remained high, and the standard version of Model 3 was slow to go into production. Tesla is still a typical luxury automaker.

Relying solely on luxury models is not sufficient to sustain a leading position. Tesla needs to achieve higher sales, stronger R&D capabilities, and larger economies of scale to widen the gap with its competitors. And the first step in achieving all of this is to increase sales to 1 million vehicles.

Model Y is the key model for Tesla to achieve its annual sales target of 1 million vehicles.

During a 2018 earnings call, Elon Musk, Tesla’s CEO, stated that the mid-size SUV market is the most popular market globally. Demand for Model Y is expected to be 50% to 100% higher than that of Model 3.

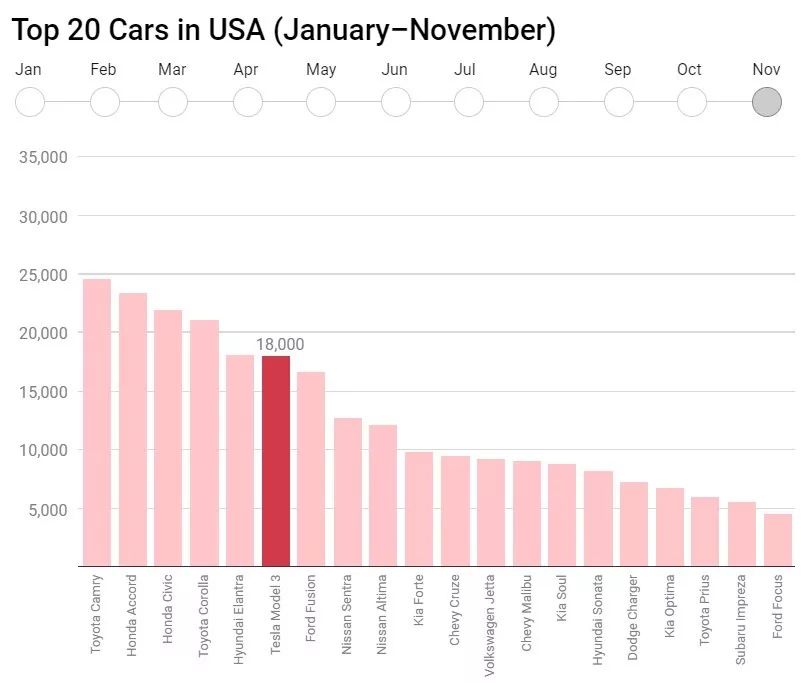

This statement is supported by data from the U.S. passenger car market sales report in November 2018, compiled by the foreign media outlet Cleantechnica.

As seen in the report, Model 3 ranks sixth with monthly sales of 18,000 vehicles, and is also the only vehicle in the top 20 with an average price of $60,000.

However, when the scope of the car models is expanded to the entire light-duty vehicle market, Model 3 immediately drops to 17th place on the list. It is also noted that the top five of the list are occupied by two pickups and three mid-size SUVs, and the Ford F series pickup, which now has a monthly sales volume approaching Tesla’s quarterly sales, takes the top spot.

This is why during the past year’s earnings calls, when mentioned Tesla’s electric pickup and Model Y, Elon swept away the “production hell” and talked more confidently. I guess he has already immersed himself in the joy of winning the light-duty vehicle sales championship two years ahead of schedule.In the Chinese market, Model Y will undoubtedly be the most popular Tesla model among Chinese consumers. In terms of the mid-size SUV market in China, the fact that almost all of the new car companies except for NIO and CHJ Automotive are focusing on producing mid-size SUVs is proof enough of the market’s potential.

Moreover, globally, the mid-size SUV market is also a major source of profits for BBA.

Before delving into the details, let’s first take a look at the overall profile of the Model Y. As a leader in the intelligent electric vehicle market, Tesla is responsible for defining the rules of the game. The key to their electric SUV’s intelligence lies in attaining the ultimate in overall vehicle safety, electromobility, automated driving assistance, and intelligent features.

Of course, as for Tesla’s traditional weaknesses, such as workmanship, quality control, and reliability, even with the Model Y, I still wouldn’t have excessively high expectations.

Therefore, the Model Y will certainly bring us many engineering and technological innovations, which is Tesla’s specialty. However, as for reliability and workmanship quality, which require time and experience to refine, it is foreseeable that they will remain a challenge. This is how I envision the Model Y.

Engineering

Elon has a famous saying: Engineering is true magic. In “Unveiling the Secrets of Tesla Model Y,” we have already discussed many of Elon’s innovative ideas for the Model Y. Now, I have some good news and bad news to share.

First, the bad news: Over the past six months, Elon hasn’t mentioned any innovative points or exciting product details about the Model Y that make him enthusiastic.

Let’s review the Model 3 for a moment. Prior to the launch of the fully automated Alien Dreadnought factory project in Q1 2017, a considerable amount of time had passed, and Model 3 had not yet gone into production, with many problems still remaining undisclosed.According to the original plan, the automated production line for Model 3 was called Dreadnought 0.5, while the Model Y production line will be upgraded to Dreadnought 3.0. At the Q1 2017 earnings call, Elon’s confidence in the fully automated factory reached its peak as the project progressed smoothly.

“This will achieve a truly “crazy” level of production efficiency that will be difficult to match by other carmakers. If I were in their position, I wouldn’t know what to do.”

During this period, he tweeted that the Model Y’s wiring harness would drop to 100 meters, only 1/15 of the Model 3’s.

We all saw what happened next, as Bernstein Research estimated that Tesla’s investment of $2 billion for the Dreadnought 0.5 around Model 3 wasn’t enough to reach the expected production capacity, and Tesla suffered a major setback.

The product innovation of the Model Y and the upgrade of the fully automated production line are inextricably linked. At the Q1 2017 earnings call, Elon mentioned that with consideration for technological innovation, the Model Y will be based on a new platform and built in a new factory. Both of these points have now undergone significant adjustments.

The Model Y will be based on the Model 3 platform, but in sharp contrast to the Model S/X, the parts-reuse rate of the Model 3/Y will be as high as 76%. Meanwhile, the parts-reuse rate for the Model S/X is only 30%, despite the basic consistency of the powertrain and chassis. This is due to the Falcon control module, 4 door modules, 3 body control modules, and numerous sensors required for the falcon wing door design.

The Model 3/Y having a parts-reuse rate as high as 76% means that the falcon wing door, which was rumored before, is unlikely to appear on the Model Y.

In addition, the plan to establish a new factory for the Model Y has been cancelled, and the Model Y production line will be located directly in Nevada’s Gigafactory 1. Gigafactory 1 already has the battery pack and powertrain production line for the Model 3/Y. According to Elon’s statement, the whole vehicle production line will be located next to the battery pack and powertrain production lines. After the two major components are produced, they can immediately enter the assembly line, thereby maximizing project execution risk reduction, as well as reducing transportation costs from California to Nevada.The goal of the financial report is to reduce unit production costs of Model Y to half of that of Model 3, while Tesla’s internal target is to lower it to 1/4 of Model 3’s unit production cost.

The background here is that since achieving profitability in Q3 2018, Elon has begun to rigorously control Tesla’s capital expenditures. A very important indicator in the 2019 guidance given at the financial report meeting is that Tesla will continue to be profitable in all four quarters of 2019 and sustainably generate free cash flow.

This reflects Tesla’s management’s reflection on and correction of the strong push for the Model 3 automated production line.

We previously proposed a viewpoint: The biggest difference between Tesla and Chinese new car companies is that as a pioneer in the entire intelligent electric vehicle industry, Tesla conducts extensive research and development in cutting-edge basic technology. This gives the product strong competitiveness, but also incurs high sunk costs.

Take the ramping up of Model 3 production capacity as an example. The total investment of $2 billion raised great pressure on Tesla’s finance, leading directly to two large-scale layoffs and a contraction of service expenditures.

Therefore, Tesla’s focus on product-centered, extensive engineering and technological innovation has not changed, but in the future, all of these will have to be carried out within a reasonable cost structure.

If we look at it this way, given the positioning of the Affordable SUV, it will be difficult for Model Y to have radical innovations in structure, such as falcon-wing doors and interior that eliminates the dashboard. It is more likely that it will be a higher and fatter Model 3.

Does this mean that Model Y is a model lacking innovation? It depends on your perspective.

To a certain extent, the slowdown of Model Y is due to the Model 3 running too fast.

Believe it or not, the product power of Model 3 is already strong enough for consumers to give up their emphasis on functionality. Below is the Model 3 owner replacement ratio disclosed in Tesla’s 2018 financial report.

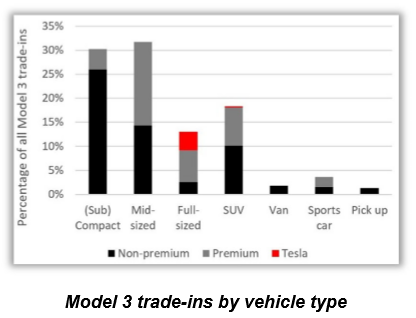

We are seeing that a significant number of Model 3 buyers are trading down in size from a larger car or a SUV to a Model 3.> We have noticed that a large number of car owners have switched from larger-sized cars (13%) or SUVs (18%) to Model 3. This chart demonstrates the market appeal of Model 3 as a midsize sedan, and, on the other hand, we can see that the replacement ratio of Van and Pick up to Model 3 is at the bottom, and the responsibility of converting these users falls on Model Y.

If the strong market appeal of Model 3 is not enough to derive its convincing product advancement, we can take a look at the Model 3 from the perspective of industry insiders.

According to Manager Magazin in Germany, Porsche and Audi engineers have reverse engineered Model 3.

“The Porsche and Audi engineers have to change the PPE, because Tesla’s Model 3 has gotten better than they thought.”

The so-called PPE, Premium Platform Electric, is a pure electric platform jointly developed by Porsche and Audi. The problem is that the first model under the PPE platform will not enter production until 2020-2021, but Model 3 has already threatened the models of the following two years?

In other words, the innovation of Model 3 is radical enough that Model Y still has strong product power even without any improvements.

Three Electrics

No improvements? Then it’s not Tesla.

The three electrics are divided into motor, battery, and electronic control.

Following the law of Model S/X, Tesla will not differentiate between sedan and SUV models in terms of powertrain. In addition, the dual motor power of Model 3 has not been fully released, satisfying the sustainable top speed of 250km/h and acceleration of 0-100km/h in 3 seconds club of the flagship Model Y without pressure.

Therefore, Model Y will be equipped with the same new generation permanent magnet & asynchronous motor as Model 3.

As for the battery, Tesla is likely to invest in some truly impressive technology for Model Y in production.On February 5, 2019, Tesla announced its acquisition of Maxwell at a 55% premium for $218 million. In “Tesla Acquires Maxwell for the Next Decade,” we briefly introduced Maxwell’s dry electrode technology, but without going more in-depth.

It is worth noting that at Tesla’s annual shareholder meeting on June 5, 2018, Elon mentioned some breakthrough progress in battery energy density and cost. He expected that within the next two years, battery costs would fall to $100/kWh, and battery energy density would increase by 30% within the next 2-3 years.

Does this “breakthrough progress” mean that Tesla has been doing technology verification with Maxwell? If this speculation is true, it means that Tesla is very likely to commercialize the dry electrode battery technology in the Model 3 Standard battery. Even if the challenges in this process exceed expectations, the dry electrode battery technology is almost certain to land by the time the Model Y is put into production in Q3 2020.

Here are some details about dry electrode technology. In 2018, Maxwell material scientist and DBE (Dry Battery Electrode) R&D manager Hieu Duong published a paper detailing the basic application and verification of dry electrode technology in existing lithium-ion batteries.

Simply put, compared to traditional wet slurry-coated electrodes, DBE-coated electrodes have three advantages:

-

Improve energy density while not affecting physical and electrochemical performance

-

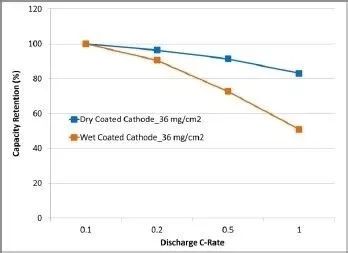

Have greater discharge power capacity than wet slurry-coated electrodes

-

Excellent battery cycle lifeThe first part of the paper is not elaborated, mainly introducing the three key processes of DBE technology, including the solvent-free powder and film manufacturing processes, which are basic technologies. However, there is a crucial sentence: this report applies a large number of mainstream negative electrode materials, such as lithium titanium oxide (LTO), positive electrode materials nickel-cobalt-manganese (NCM), nickel-cobalt-aluminum (NCA), lithium iron phosphate (LFP), and various sulfur/carbon-silicon composite materials, demonstrating the robustness and scalability of dry battery electrode technology.

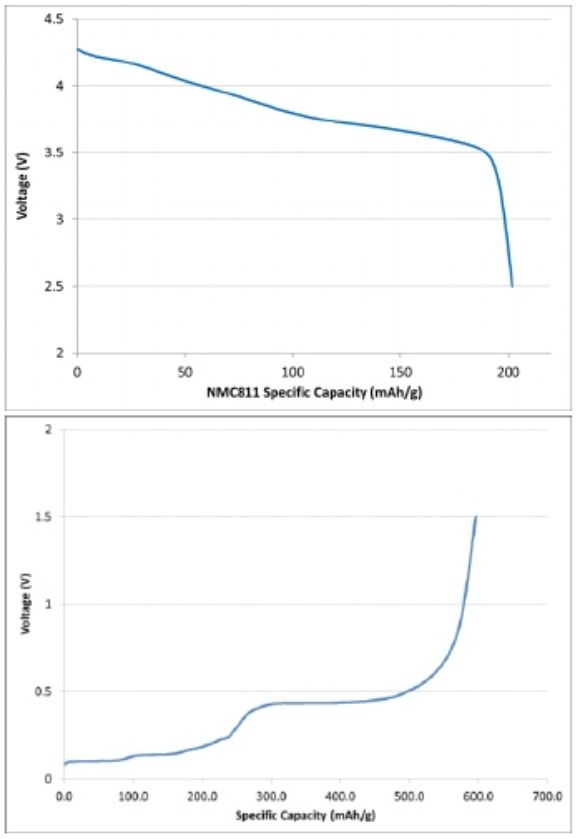

Below are the discharge voltage curves of NCM811 dry electrode and silicon-carbon negative electrode. The silicon-carbon negative electrode dry electrode shows unique electrochemical characteristics at around 0.5V, resulting in significant improvement in battery energy density.

Comparison between NCM111 wet-coated traditional electrode and Maxwell dry electrode for graphite anode: under the same 105mAh battery capacity, the dry electrode exhibits a higher discharge power.

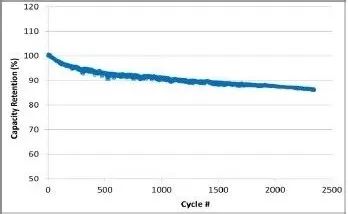

100% charging and discharging cycle test at 0.5C/1C rate: after 2000 cycles, the battery capacity is still nearly 90% of the initial value.

In summary, dry electrode batteries have shown 15-50% improvement in various indicators compared to the 2170 batteries used in Model 3. The key information of the paper was presented in more specific technical indicators based on the technological breakthroughs in the Maxwell investor report on January 16, 2019.

- Energy density: verified as >300 Wh/kg, with a path to achieve 500 Wh/kg

- Extended battery life: improved durability, doubling battery life

- Reduced cost: 16 times increase in production capacity density, cost reduction of 10%-20% compared to wet electrode technologies

- Technical support and environmental responsibility: solvent-free, next-generation materials, cobalt-free, solid-stateWhy are we optimistic about Tesla’s production of Model Y dry electrode battery technology? That’s because once the dry electrode technology that is almost compatible with mainstream positive and negative electrode materials on the market is put into production, the technological advancements achieved will not be exclusive to Model Y. All of Tesla’s models and energy storage products will benefit from it.

From this perspective, even if Elon pulls back on the cost sinking for sustainable profitability, he will not hesitate to make a reasonable investment in research and development.

From Tesla’s past product regulations, we can see that if the flagship Model S can upgrade from the 2012 P85 RWD to the P100D in August 2016, then it is difficult for the battery specification of Model 3/Y Performance to stay at an available capacity of 75 kWh forever.

Considering that the acceleration of electric vehicles per 100 kilometers is directly related to the discharge power of the battery pack, and that the motor power of Model 3/Y currently matches an oversized battery pack, it is not impossible for the acceleration of these two models to enter the 3-second or even 2-second club in the future.

Always believe that good things are about to happen.

Vehicle Safety

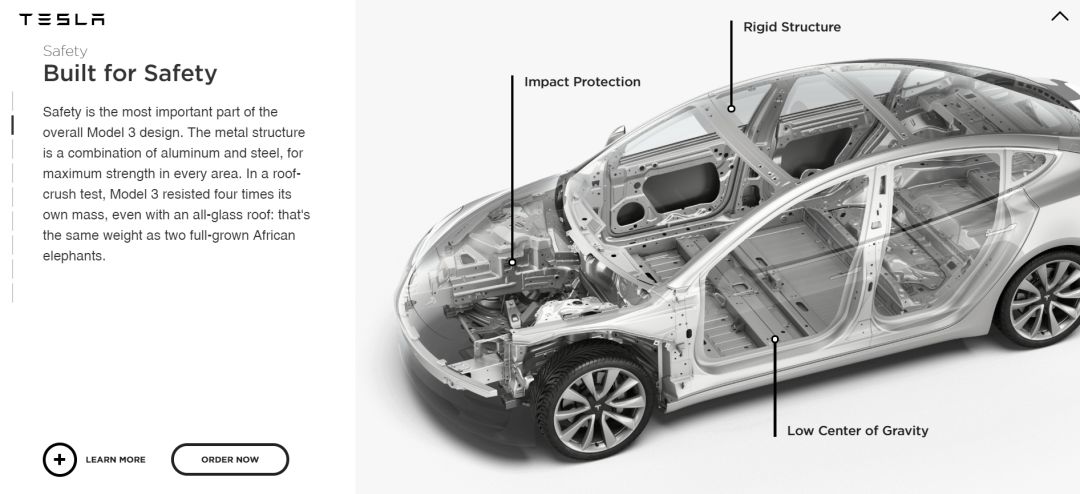

There’s not much to say about Tesla’s vehicle safety, but if you open the redesigned Tesla USA website, you’ll find that the first item on the product page for all three models is vehicle safety, which is the most important point for Tesla’s product development team. So let’s talk briefly about it.

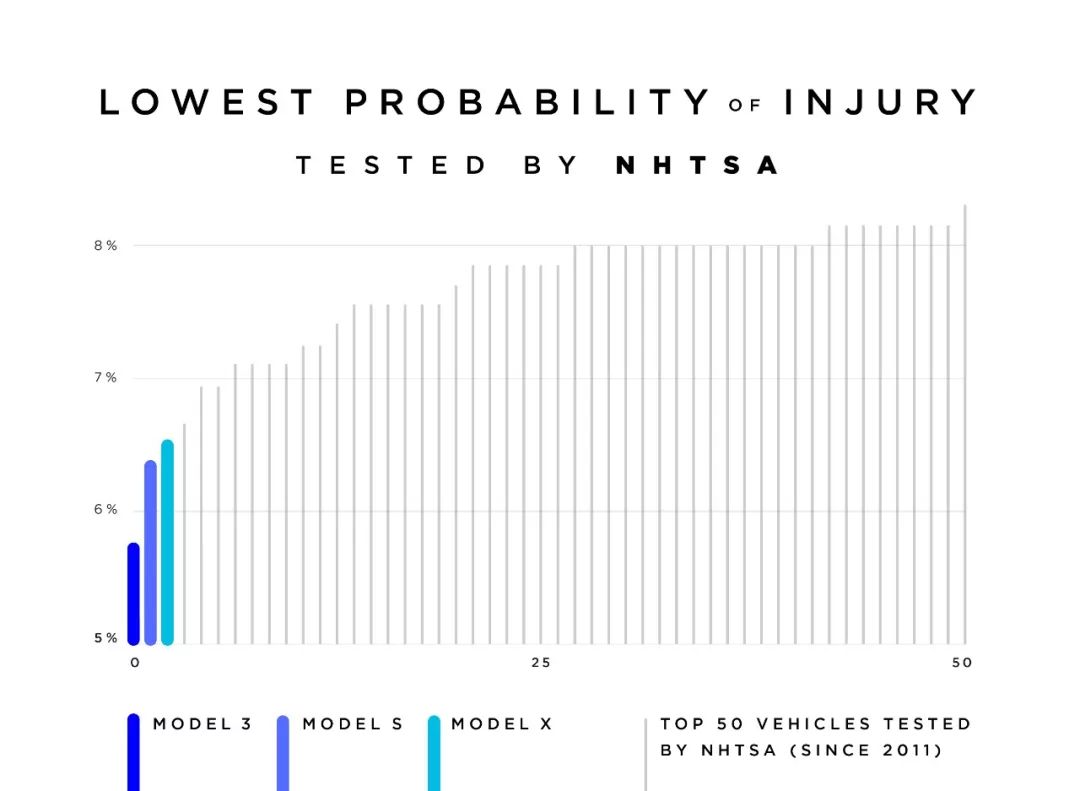

On October 7, 2018, the Tesla team released a blog post: Model 3 is the safest car among the 943 five-star safety rated vehicles tested by NHTSA (National Highway Traffic Safety Administration) since 2011, with the lowest probability of injury, followed by Model S and Model X.

At the Q3 2018 earnings call, Tesla’s chief safety engineer, Madan Gopal, explained Tesla’s understanding of safety in detail.

I want to say a couple of things about how we think about vehicle safety. It’s something that Elon cares about deeply. You can look at how the Model 3 performs in the full front crash test, which isn’t even a part of the new car assessment program. What I’d say is that we exceed these new car assessment program requirements to ensure that our vehicles are safe, and that’s really important to us.For Model Y, some previous experience, including the weight distribution approaching 50:50, ultra-low center of gravity design, and specially designed safety airbag layout, will probably be inherited, so there is no need to worry about Model Y’s performance as a five-star safety vehicle.

In terms of active safety, Autopilot is an unavoidable topic. Although Elon’s current public statements tend to be conservative, and the promised functions of AP are always delayed, the progress of Autopilot has been obvious in the past two years since the production of AP 2.0 cars from October 2016. Without a doubt, Model Y will come standard with AP 3.0, and aside from the unsurprising AI chip, we can look forward to an updated sensor suite.

Based on past improvement efficiency and an 18-month timeline given to the AP team, we have reason to believe that Tesla can handle all-time autonomous driving in high-speed scenarios (which does not imply policy and regulatory readiness) when Model Y goes into production.

Design

After saying so much, we still need to take a look at its appearance.

As mentioned earlier, as the first product under the new strategy, Model Y will not have bold designs and engineering innovations. On the one hand, this is due to cost control, and on the other hand, it is because Model 3 is advanced enough.

Unless there are unexpected changes, its final form will not deviate much from these rendered images:

This is the Tesla Model Y, see you at the launch event.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.