The year 2018 has passed.

Elon Musk said that it was the most difficult and painful year in his career.

But Nietzsche said, What does not kill me, makes me stronger.

Will Tesla’s future be better?

Product Curse

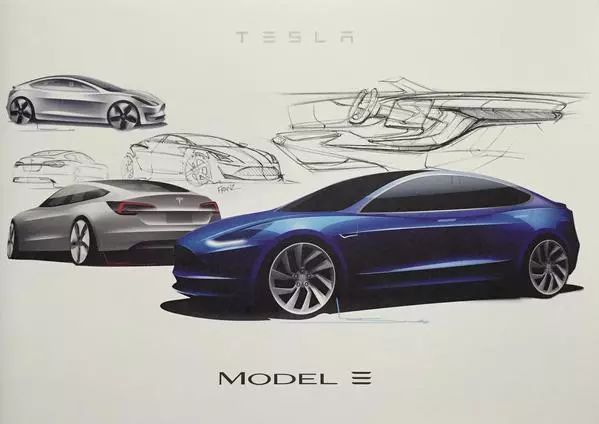

In the past 18 months, there have been numerous reports on the production hell of Model 3. What happened to Model 3?

Today, we can see it more clearly: Model 3 cannot break out of Tesla’s product curse. It is a hardcore challenge for Tesla after Model X.

Let’s break it down.

Roadster: The first product. If Tesla had failed to achieve Roadster’s production ramp-up and delivery at a reasonable cost structure in 2008, it would have gone bankrupt.

Model S: The second product, more precisely, the first product that pushed Tesla from an electric sports car manufacturer to a luxury car manufacturer. If Tesla had failed to achieve Model S production ramp-up and delivery at a reasonable cost structure in 2012, it would have gone bankrupt.

Model X: The third product, as an SUV product on the same platform as Model S, was not so critical in the development of Tesla.

However, designs such as panoramic windshields and double helix induction falcon wing doors caused the parts reuse rate of Model S/X to drop to 30%, making Model X the most difficult car to manufacture in the world. The challenge facing the Tesla team is no less than developing a brand new model.

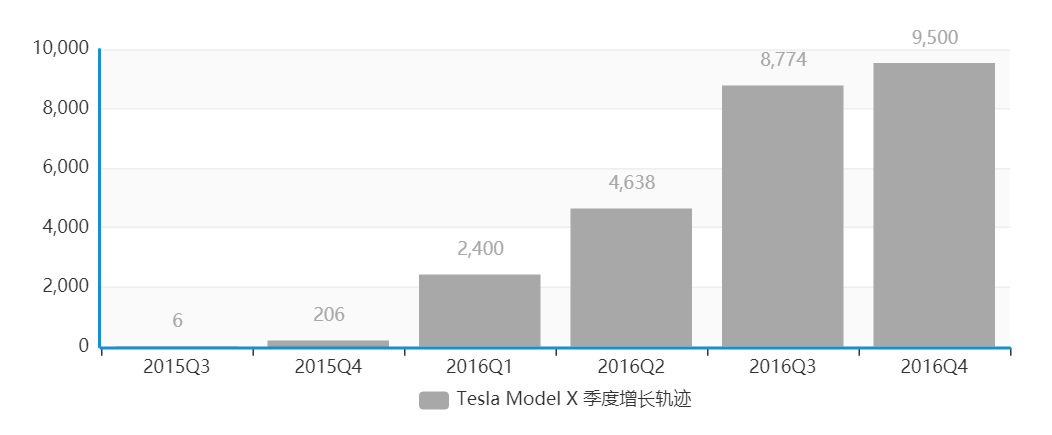

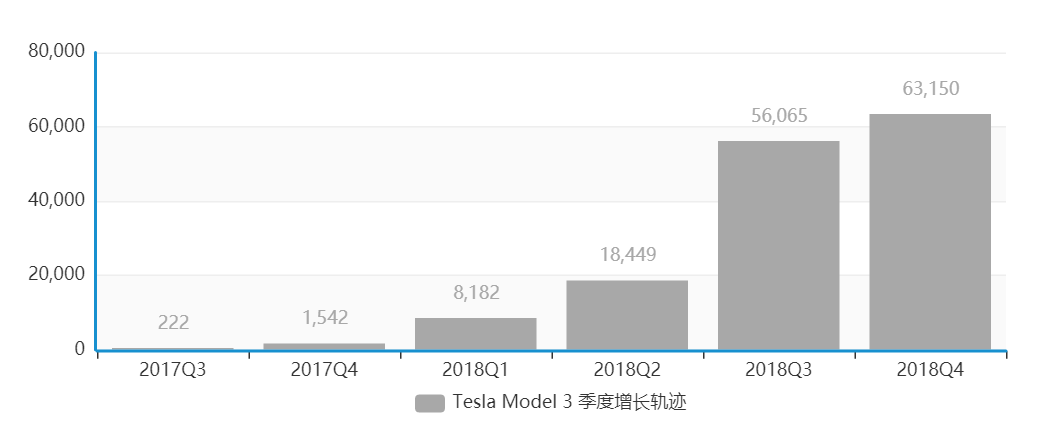

What about Model 3? Actually, we can compare the production ramp-up trajectory of Model X and Model 3.

In September 2015, Tesla delivered the first batch of Model X. However, after that, Tesla experienced several problems, such as suing Model X’s falcon wing door supplier and seat capacity constraints. It was not until Q4 2016 that Model X’s production capacity and delivery scale reached a relatively stable rhythm.

## Tesla’s Struggle With Model 3 Production

## Tesla’s Struggle With Model 3 Production

In July 2017, Tesla delivered the first batch of Model 3s. However, the battery production line and the four major manufacturing processes subsequently encountered a capacity hell. It wasn’t until Q4 2018 that Model 3’s capacity and delivery scale reached a relatively stable rhythm.

It is incredibly similar to a curse – a very typical Tesla-style product curse. Lifting this curse requires the project team, and even the entire company’s management, to bear huge pressure, invest massive amounts of money, and overcome difficult technical challenges for a whole year to keep the capacity stable.

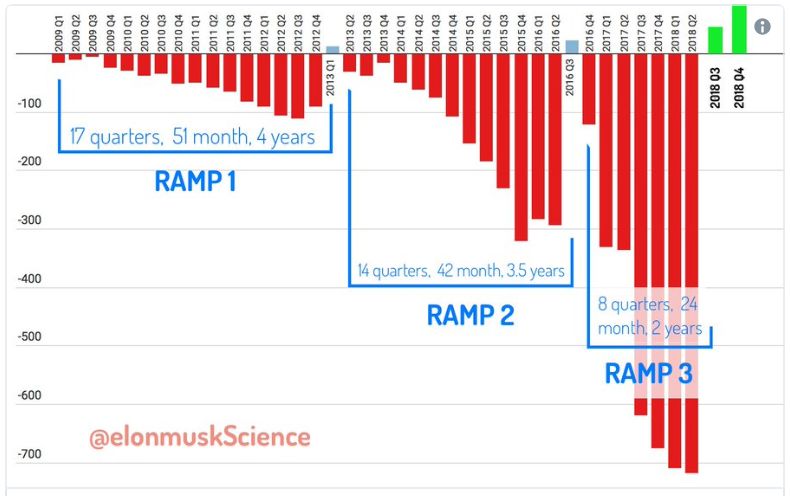

The table displays financial data from Q1 2009 to Q4 2018. You can see that in Q2 2012, Q2 2015, and Q3 2017, the delivery of the first batches of Model S, Model X, and Model 3 respectively corresponded to rapid capital expansion, but in reality, all started from the dark before dawn. For example, Tesla achieved profitability again in Q3 2018.

If the above is all Tesla in 2018, the story would end here. Obviously, the truth is more complex than appearance.

Model 3 Capacity Ramp Failure

A conclusion can be drawn: Elon’s capacity ramp plan for Model 3 has largely failed.

Focus on the data from the last two quarters in the previous two pictures. The growth rate has decreased, and the trend has become uniform. This means that Tesla’s capacity can already meet the market demands of the quarter, fully addressing the production issues of Model X.

However, this is not the case for Model 3. Even until today, Tesla is still unable to process more than 200,000 Model 3 orders, which means that its stable capacity is not due to market demand being met, but because the capacity ramp failed.

As “the world’s most difficult car to manufacture,” Model X took Tesla a whole year to solve its capacity issue. How complicated is Model 3?

At the 2017 Tesla shareholders meeting, Elon introduced the design logic of Model 3 to shareholders.>Model 3 has been specifically optimized for “ease of manufacturing”, it is simpler than Model S/X, and many of the bells and whistles on Model S/X have been cut from Model 3. This design can significantly reduce risk and accelerate capacity improvement in subsequent production climbs.

But what is the reality? On July 1, 2018, Elon sent an email to all employees announcing that Tesla’s Model 3 production capacity had increased to 5,000 vehicles per week at the end of Q2. On January 2, 2019, Tesla released the Q4 2018 production and delivery announcement, showing that Model 3 production capacity hovered around 4,500 vehicles per week.

For a full 6 months, Model 3 production capacity stagnated. In Tesla’s history, this challenge was unprecedented.

In fact, the challenge Model 3 brought to Tesla was far greater than Model X.

Where did the problem arise?

A little more radical

Let’s turn the clock back to 2015 for a deeper understanding of why Tesla’s 2018 proved to be so difficult.

In January 2015, Elon held a secret meeting of top engineers at the Tesla Fremont plant to discuss the specific requirements and implementation of the Blue Star Project. Twelve top experts in different areas, including Tesla’s design, battery, chassis, interior, body, powertrain, safety and thermodynamics, sat down to discuss.

After the meeting, the Blue Star Project officially began (in Tesla’s 2007 business plan, Elon named the “affordable sedan project” the Blue Star Project).

The original research and development period was set to start in January 2015 and deliver by the end of 2017. That is, Model 3 was originally developed with a 35-month research and development period.

According to the traditional development cycle of car companies, the development cycle of a car should be 48-60 months. The NIO ES8, which has undergone multiple tests and synchronous development and adopted the strategy of “spending money to save time” in multiple links, had a development cycle of 38 months. Therefore, even according to the original plan, Model 3 was the shortest development cycle car in history.

As Elon said, Model 3 was the last bet on the fate of the entire company. From the very beginning, the entire company has been pushing the Model 3 project with an all-in attitude.

In October 2015, just one month after Model X began delivery, most Tesla engineering staff withdrew from the Model X project and moved into the Model 3 development team.

During the Christmas period of 2015, there was no vacation for Tesla’s design studio. The interior team led by the chief designer, Franz von Holzhausen, finalized Elon’s “a central touch screen displays and controls all information,” as well as the “no visible air vents” design.

Everything seemed to be moving in the right direction until May 2016, when everything changed.

Elon called a meeting to announce that Tesla will increase its production capacity to 500,000 vehicles per year by 2018. This is 15 months earlier than the previous plan and 24 months earlier than the initial plan. To support this new goal, all business progress needed to be adjusted.

In May 2016, Tesla made a series of intensive adjustments around the Model 3 project.

Firstly, the Model 3 production node was moved up by 4 months to start on July 1, 2017. This means that the research and development cycle of the Model 3 was reduced to 30 months.

Secondly, the production capacity goal of Gigafactory 1 in Nevada was brought forward to 50 GWh/year by 2018 to meet the demand for 500,000 vehicles per year of battery packs.

Thirdly, the commercialization of the 2170 battery with higher energy density and lower cost was accelerated, and the cost target of $100/kWh was brought forward to 2018 from 2020.

Then, all suppliers were notified to adjust their production capacity. It is estimated that the production capacity of the Model 3 will double to 100,000 vehicles per year in 2017 and reach 400,000 vehicles per year in 2018 (in addition to the stable sales volume of 100,000 vehicles per year from Model S/X, making a total of 500,000 vehicles per year).

Finally, the Model 3 project development team was drawn and formed the “Model 3 automated production line” project development team, led by Senior Vice President of Engineering Doug Field.The last part, which is also the core of the 500,000 units/year production capacity plan, is the automated factory that Elon refers to as “The machine that makes the machine.” After that, Tesla acquired two automation manufacturing robot companies Grohmann Engineering and Perbix to deepen understanding of automation.

Despite making comprehensive adjustments and deploying a series of intensive measures, as you know, the Model 3 production ramp plan has basically failed.

A key issue is, when everything was progressing smoothly, why did Elon decide to be “more aggressive” in May 2016?

“Fearless Ship”

In March 2016, Tesla had just released the milestone electric car Model 3 in the intelligent electric car industry.

How did the two months pass? Before the press conference, Tesla and SpaceX employees had ordered over 10,000 units. Within 24 hours after its release, orders increased to 115,000, and after 48 hours, backorders reached 232,000. Ultimately, orders exceeded 500,000 and continued to grow.

And Tesla’s most aggressive order forecast internally was only 50,000 units. In other words, market enthusiasm exceeded Tesla’s most optimistic expectations by an order of magnitude.

This kind of enthusiasm from all over the world is both recognition and pressure. After that, Elon’s focus shifted from “how to make the best intelligent electric car” to “how to make the most efficient and fastest production ramp factory.”

When his attention was focused on cars, Tesla made models like the Model S P100D. When he seriously examined the production line of cars, what would happen?

On May 31st, 2016, at the Tesla shareholder meeting, Elon shared his thoughts on factories.

In the past two or three months, I gradually realized that the potential for improving car production is ten times higher than the potential for improving car engineering itself.

We realize that this is the real problem and challenge, and also where the greatest potential lies. We are building the machine that makes the machine and truly treating the factory itself as a product, a vertically integrated product to build. We see the problems that occur in the factory more as engineering or technical challenges to solve.> Dreadnought is unlike any other automotive production line you’ve seen. We don’t have workers around the line, as they would slow down the production speed. In fact, there are no workers involved in the whole production line. Workers are replaced by engineers whose responsibilities are maintenance, upgrades, and dealing with unexpected situations of the manufacturing robots.

With the same area, the production capacity of Dreadnought will be 10 times that of traditional production lines. Without a doubt, this is a scene that can only be achieved in highly intelligent and automated robot production lines in science fiction movies. But the huge pressure from Model 3 orders made Elon’s team push for the implementation of Tesla’s automated production line in 2018.

At the Tesla Q3 earnings call in November 2017, Jon McNeill, Tesla’s Global Sales and Service President, briefly discussed the difficulty of designing Dreadnought.

“Dreadnought is an extremely complicated machine with combined electrical, mechanical, and software challenges. It’s not that different than what we do bringing up a brand-new car.”

Jon McNeill was wrong. In fact, with the technology level of 2018 or today, such a production line cannot be implemented at all.

In August 2017, the first batch of Model 3 had been delivered. However, the robots on the Model 3 production line still could not reliably recognize and grab wires of different colors and put them on the conveyor belt to transport them to the required workshop. Due to the inability of the production line to operate, Tesla had to use a large number of manual interventions to build the first 30 Model 3s.

By February 2018, the problem of the non-working automated production line had become apparent. But Elon attributed the problem to the difficulty of adjusting and improving supplier solutions, and asked the Doug team to take over the development work of the entire production line, hoping to better understand where the problem lies and how to solve it through independent research and development.

The final version of Dreadnought consists of 5 workshops, over 1,000 manufacturing robots, and 0 workers. The Tesla team designed dozens of sub-lines to combine into a complete Dreadnought.

Overestimated Robots, Underestimated Humans.It includes four fully automated production lines and a super complex network of component conveyors with the participation of multidisciplinary teams including various talents such as sensors, computer vision, robotics, automation, software engineering, mechanics, electronics, and electrical engineering.

The only problem is the dismal operating efficiency. Tesla’s team has been unable to solve problems such as bolt perforation, accurate identification and capture of wire harnesses, sensor failure, and a large number of robot crashes and reboots.

The most exaggerated incident occurred when the component conveyor belt stopped working, causing 100 Model 3 vehicles to roll off the assembly line without the right headlights. Tesla eventually retrofitted these models with headlights, but the problems with the automated production line could no longer be ignored.

In April 2018, Elon’s expectations for improving the automated production line plummeted, or rather, he became more aware of the challenges he faced. Tesla finally dismantled the production line and instead launched a new semi-automated, more labor-intensive production line.

The tent-covered No.3 final assembly line had significantly increased manual labor involvement.

This was the first time Elon publicly admitted that over-automation was a mistake; to be precise, it was my mistake, and humans were underestimated.

The dismantling of the production line is still profoundly affecting Tesla’s development, particularly in terms of the production line itself. Many people have no concept of the investment required to “build and dismantle a production line,” let alone Tesla’s first-of-its-kind fully automated production line that involved a large amount of research and development.

Elon himself claimed that Tesla burned through $50 million to $100 million per week at its peak, and third-party company Bernstein Research estimated that Tesla invested approximately $2 billion in the Model 3 automated production line.

What is the concept of $2 billion? It’s the same as the design investment of Tesla’s Shanghai Super Factory Gigafactory 3.

As a listed company, it is inevitably costly to spend billions of dollars on trial and error.

It could be said that there was a personnel earthquake and organizational restructuring.# Elon Musk: Leading by Example

Elon Musk believes in leading by example. When asked why he sleeps on the factory floor and works 120 hours a week without leaving, he explained that he wants his team to understand that no matter how difficult the work is for them, he is the one who has it the hardest.

However, the unprecedented and long-term high-intensity work with high pressure has made Elon extremely emotional, as evidenced by his rash initiation and termination of Tesla privatization and disputes with the media on Twitter in mid-2018.

All management is under immense pressure. Although it is not uncommon for executives to leave Tesla, the departure of core aides has still affected Tesla’s development to some extent.

- In February 2018, Jon McNeill, Tesla’s Global President of Sales and Service, left the company.

- In May 2018, Doug Field, Tesla’s Senior Vice President of Engineering, announced he would take a break (and then left the company).

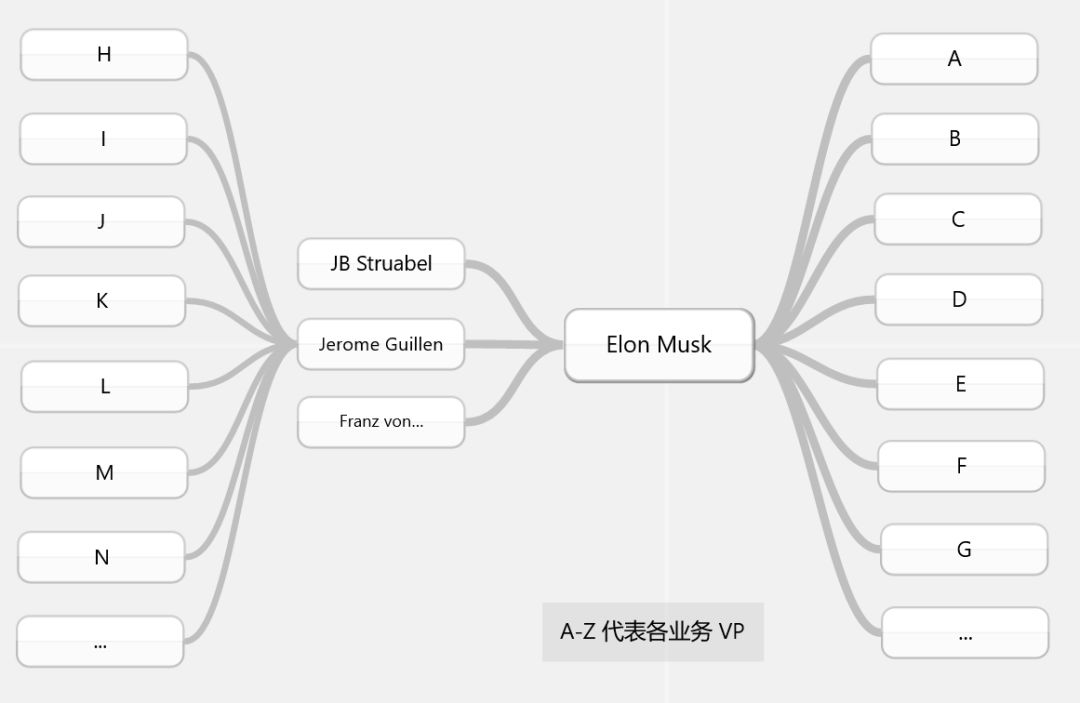

The titles of these two executives are crucial. Tesla has dozens of vice presidents or similarly ranked senior executives, but only Jon McNeill dropped the “vice” and Doug Field added “senior.”

Tesla does not have a COO, and Jon and Doug played the role of co-COO, acting as a liaison between Elon and dozens of senior executives at Tesla.

In Tesla’s six core businesses, Jon was previously in charge of sales, service, and charging, while Doug was responsible for design, manufacturing, and engineering. Except for the engineering, design, and Autopilot teams, which report directly to Elon, all other VP’s in charge of these six business units report to Jon and Doug.

After the departure of these two executives, all business VPs began reporting directly to Elon. On September 7, 2018, Elon completely restructured Tesla’s organizational structure to a more extreme flat model.

Former head of Model S, Semi Truck, and current head of Model 3 project, Jerome Guillen, has been promoted to become president of Tesla’s automotive business in a restructuring.

On June 12, 2018 and January 18, 2019, Elon launched two rounds of layoffs after six months. Elon’s rationale for the first round was that the rapid expansion of the Tesla team in recent years led to “job overlap” and some positions were no longer necessary. The reason behind the second round of layoffs was more straightforward: Tesla needed to reach the scale effect required for the production of the standard version of Model 3 through layoffs, manufacturing design improvements, and capacity ramping up in order to achieve the launch of the Model 3 standard version.

It should be noted that Tesla hired 8,000 new employees in 2018, and after two rounds of layoffs of 9% and 7%, over 7,000 employees have been let go. Broadly speaking, with roughly the same team size from 2017 to 2018, Tesla has achieved a doubling of production capacity, deliveries, and operational performance.

Next, because of the detour taken by the fully automated production line, the collective release of all business and new products was delayed.

In the second half of 2018, the production capacity of Model 3 was stagnant, directly leading to the failure of the annual production target of 500,000 vehicles; the spin-off effects included the failure of Gigafactory 1 to achieve 50GWh of production capacity;smaller scale effect led to the failure of battery costs to reach $100/KWh, resulting in the delay of the mass production time of the $35,000 Model 3 and the subsequent delay of the Semi Truck production plan.

You will find that Tesla’s product portfolio planning is interlocking and seamless. Once one link is broken, the whole system will be affected. Now, the broken link is the failure of Model 3 to achieve mass production.

A Bright Future Ahead

Looking back, all of the difficulties encountered by Tesla in 2018 stemmed from their radical plan in May 2016. If there were no Dreadnought, there would not have been so many difficulties and challenges at that time.But all decisions are not made on a whim. The reason why Tesla has chosen Model 3 as a guinea pig to test the fully automated production line is because it is the most likely model in the industry to achieve fully automated mass production. In addition to the well-known significantly enhanced integration and reduced manufacturing complexity, Model 3 has lowered to 10,000 parts and 1.5 km of wire harness. The final assembly workshop of Model 3 only has less than 50 processes, simplifying 70% compared to traditional models.

Although it ultimately failed, and at the cost of billions of dollars and executive turnover, as the saying goes, “practice makes perfect.” Tesla’s understanding of automation robots and the design experience of dozens of sub-lines in the Model 3 production line will undoubtedly return in the production of Model Y next year.

Some people may say that in today’s awakening of traditional automakers, Tesla has not only lost executives, billions of dollars, and the inability to achieve an annual production capacity of 500,000 in 2018, but also the largest loss is the wasted period of time.

Regarding this statement, I would like to quote a paragraph from Elon’s biography “Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic Future.”

A former Space X executive gave a metaphor: It’s like Elon asked everyone to build a car, but only used one box of gas to drive from Los Angeles to New York. When the test was ready to drive the car to New York, everyone thought that one box of gas could only drive to Las Vegas at most, but they ended up driving to New Mexico, which was twice as much as everyone expected.

Remember, Tesla’s original plan was to achieve an annual production capacity of 500,000 by 2020. Although it was not achieved in 2018, even if delayed until 2019, it is still a year ahead of the original plan.

No traditional automaker will think about problems in this logic and adjust their plans.

2018 was Tesla’s most difficult year since its establishment, but it was also its most successful year. As Elon said, today’s Tesla has the most exciting product roadmap among all consumer product companies on Earth. Fully automatic driving Autopilot, Model Y, Semi Truck, Roadster, Powerwall, Powerpack, and SolarRoof, this is an incredibly powerful and perfect closed-loop product portfolio.

Will Tesla’s future be good?

* The Evolution of Tesla: The Survival Philosophy Behind Risk-taking

* The Evolution of Tesla: The Survival Philosophy Behind Risk-taking

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.