Weekly Index Ranking

Note: The data are accumulated by both Dianka and Tianji for the launch of Dianka’s new brand Tianji.

Weekly News

WM Motor releases new policy for local subsidy, with the deadline locking in Xpeng G3 one day before its launch

On November 28, WM Motor introduced the FAST PASS plan, which mainly focuses on customers who have purchased WM EX5 300, WM EX5 400 models, and completed the payment before December 11, 2018 (including that day) on an e-commerce platform as well as paid the full price to WM’s partner station before December 26, 2018 (including that day). WM promises that such customers can pick up their cars before January 31, 2019, and enjoy the national and local subsidies for 2018.

The cities covered by this plan are Beijing, Tianjin, Langfang, Jinan, Qingdao, Shanghai, Nanjing, Suzhou, Hangzhou, Wenzhou, Chengdu, Zhengzhou, Wuhan, Xi’an, Shenzhen, Guangzhou, Hefei, and Taizhou (among which Langfang, Jinan, Qingdao, Zhengzhou, Taizhou, and Hefei have no local subsidy policies and do not enjoy such preferential treatment). The chosen city of participation coincides with the city of the customer’s car registration.

On November 30, WM announced that the delivery of cars originally scheduled to be delivered before November 30 would be delayed due to the adverse weather conditions. WM is committed to delivering the cars to customers within a maximum of 7 days and no later than December 7. Before the delivery, WM will report to the customers about the vehicle transportation status and location every day, and compensate the affected customers for their loss with points according to its previously agreed policy.

Comment: WM’s FAST PASS plan has finally eased the concerns of consumers who want to buy WM but are worried about the subsidies. This shows that WM cares about its customers. The deadline for purchase coincides with the day before Xpeng Motors’ G3 launch. It is unnecessary to emphasize how important the first batch of customers’ reputation is for a new brand. WM must not lose the big picture for the small gain.

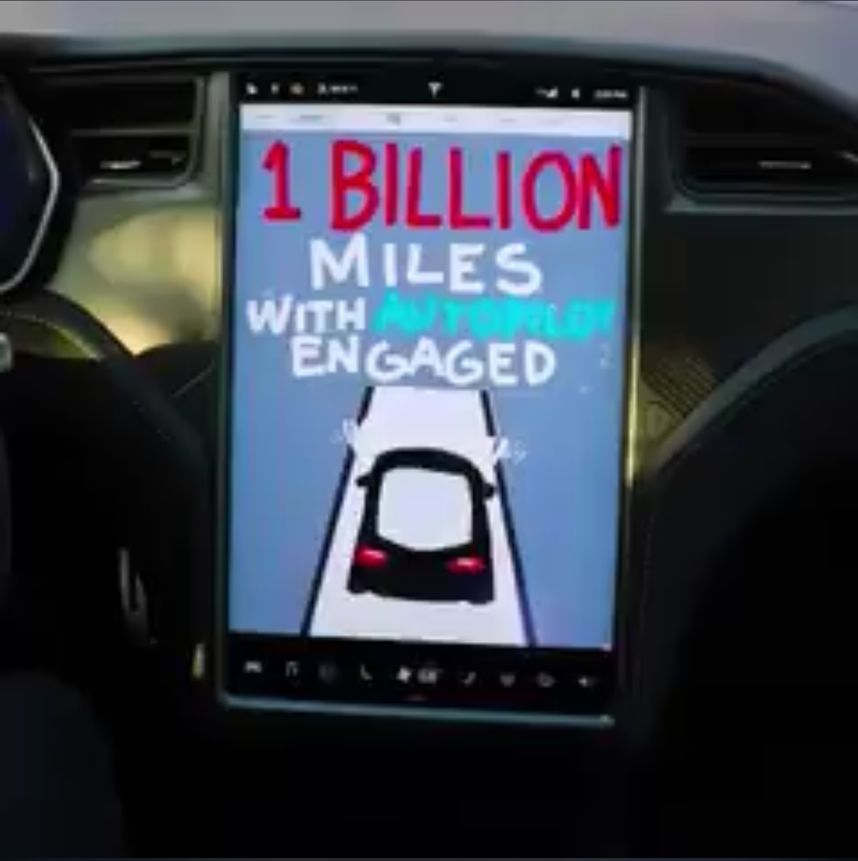

Tesla’s Autopilot has driven over 1 billion miles

Tesla Autopilot has driven over one billion miles

On November 29, 2018, Tesla officially announced that Tesla owners had driven over one billion miles (1.61 billion kilometers) while using Autopilot, a feature that provides automatic assistance while driving. Tesla vehicles have driven a total of 10 billion miles.

Quick Comment: While the number doesn’t necessarily surprise me, I was impressed by how Tesla chose to promote this milestone. Rather than producing an elaborate video or image, Tesla displayed the achievement on the large screen in their vehicles, saving on advertising costs while highlighting their creativity. I’m also looking forward to what kind of Easter eggs Tesla will provide for customers during the upcoming Christmas season. If you’re a Tesla owner, share what kind of creative Easter eggs you’d like to receive in the comments section.

NIO preparing to deliver 10,000 ES8 vehicles, while ES6 opens for pre-orders

NIO’s ES8 production ramped up in November, with a total of 3,089 ES8 vehicles delivered, a 96% increase from the previous month. As of November, NIO has delivered 8,030 ES8 vehicles, approaching their goal of 10,000 deliveries.

At the same time, the ES6 is set to be released soon, with NIO releasing several details about the upcoming SUV:

- The car is slightly smaller than the ES8 with a wheelbase of 2900mm

- Dual motors are included (expected to be AC asynchronous motors)

- Battery pack size is identical to the ES8 with a capacity of at least 70 kWh and with a maximum range not less than 400 km

- Price starts at 370,000 RMB before subsidies

- Pre-orders open on December 1, and the car will be officially unveiled on December 15, with deliveries set to begin in mid-2019.

## ES8 Production Ramping Up, ES6 Launch Imminent While NIO NA CEO Warrior Resigns

## ES8 Production Ramping Up, ES6 Launch Imminent While NIO NA CEO Warrior Resigns

NIO NA CEO Padmasree Warrior announced that due to personal reasons she will resign from her position on December 17th. Warrior joined NIO in December 2015 to lead the software development and overall management for the company’s North America operations.

ES8 is about to achieve the milestone of 10,000 units produced, which is surely not an easy feat. The upcoming ES6 model is of great significance for NIO. Moving forward, who will take on the greatest challenge of software development on their journey? Hopefully, there will be no software troubles after the delivery of ES6.

Quick Comment: The electric vehicle market is advancing rapidly. The obstacle of software development is considered the biggest challenge. It seems there will be a large wave of battery factories being built worldwide in the next five years to keep up with the transformation of the energy structure.

SK Innovation Plans to Invest KRW 1.14 Trillion (CNY 6.15 Billion) in Building a Battery Factory in the US

On November 26th, 2018, SK Innovation, a subsidiary of SK Group responsible for the production of power batteries, held a board meeting in Seoul, South Korea, and decided to build a new power battery factory in Jackson County, Georgia, in the United States.

The factory is expected to start production in early 2019 and reach full capacity in 2022. It will have a total investment of KRW 1.14 trillion (CNY 6.15 billion) and an initial annual production capacity of 9.8 GWh. By adding additional investments later, it is expected to reach an annual production capacity of around 55 GWh.

Industry insiders believe that the site selection plan is closely related to Volkswagen. According to Volkswagen’s plan, they will launch 50 electric vehicle models under their brand by 2025, and they will need a battery capacity of nearly 150 GWh per year to meet their rapidly growing demand.

Quick Comment: Electric vehicle technology is advancing, and power batteries are the core technology. Not only Volkswagen, but other traditional car companies are also facing this challenge of technology transformation. It seems there will be a large wave of battery factories being built worldwide in the next five years to keep up with the transformation of the energy structure.

Rivian Automotive Unveils Its First Electric Pickup Truck with a Maximum Range of 644km

Rivian Automotive has released their first electric pickup truck with a range of up to 644km.

At this year’s Los Angeles Auto Show, American automaker Rivian Automotive unveiled its first electric pickup truck, the R1T, which boasts impressive specifications.

-

The vehicle measures 5475*2015*1814 mm and has a wheelbase of 3450 mm.

-

Each wheel is driven by an independent electric motor, with a maximum output of 200 horsepower per motor and a total output of 800 horsepower. It can go from 0 to 96 km/h in just 3 seconds.

-

The battery comes in three sizes: 105 kWh/135 kWh/180 kWh, with corresponding EPA combined range of 370 km/483 km/644 km, respectively.

-

The maximum charging power is 160 kW.

-

The starting price in the United States is $69,000, and it is expected to be delivered in 2020.

Commentary: The R1T’s massive size enables it to have a battery capacity of up to 185 kWh and a range of a staggering 644 km. The figures are impressive, but the starting price of almost $70,000 is not very accessible to the pickup truck market. Whether the product will be worth it can only be determined by the actual delivery of the vehicles in 2020. One wonders if Tesla, which also has plans to enter the pickup truck market, is worried about its first competitor.

Haima XPeng Intelligent Factory Unveils Its Mystery

On December 1st, Haima XPeng Intelligent Factory unveiled its mystery. The factory, which was jointly built by Haima Automobile and XPeng Automobile in Zhengzhou, Henan Province, covers an area of 450,000 square meters, with a total investment of more than 2 billion RMB in the first phase, and a production capacity of 150,000 vehicles per year.

The Phase 1 body welding workshop covers an area of 21,500 square meters and has a four-car type flexible production line, providing mixed-line production capabilities for different platform bodywork components. The paint workshop covers an area of 72,000 square meters and uses a compact water-based paint technology called B1B2, which includes pre-treatment electrophoresis line, weld seam glue spraying line, polishing line, painting line, inspection and finishing processes, and can achieve mixed-flow production of multiple models. The final assembly workshop covers an area of 24,000 square meters and includes interior assembly lines, chassis assembly lines, power assembly part assembly lines, front and rear axle assembly lines, door assembly lines, instrument assembly lines, and front end module assembly lines, with an independent vehicle testing workshop.

Quick review: Following NIO, XPeng Motors has chosen the OEM model for vehicle production. The manufacturing technology of Haima Automobile needs to be considered, and a key challenge that new carmakers face in mass production is the problem of capacity ramp-up, so it remains to be seen whether XPeng, who is late to the game, is adequately prepared.

-

Aiways unveils latest design of U5; NIO ES6 to be released next month | E Weekly News

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.