Elon Musk’s Confidence in Making Troubles

Where has Tesla come to now? On August 8th, Elon suddenly tweeted to announce privatization, and the board immediately issued a statement: Elon had discussed with the board last week on how to privatize the company to better serve Tesla’s long-term interests.

On August 24th, Elon wrote another blog post announcing his change of mind, with the board’s statement immediately following: Elon informed the board that, after considering all the factors with his advisors, he believed it was better to no longer pursue Tesla privatization.

On September 7th, during Joe Rogan’s podcast interview, Elon successfully sold a Model S P100D to his gasoline car supporter Joe Rogan, and then took a puff of weed on camera 🙂

As of now, the board’s statement on Tesla privatization has not yet been released, probably giving zero fucks about it.

The privatization has caused Tesla’s market value to evaporate $12 billion, with a puff of smoke wiping out another $4 billion. I guess the Tesla board is indulging Elon, giving him complete free rein.

Why are they spoiling him like that?! Now, let’s move on to the Model 3.

Regarding the reason for hastily initiating Tesla privatization, Elon mentioned one reason was that Tesla’s hardest times had passed, and if action were not taken now, performance-oriented market value growth would soon make it impossible for any consortium in the world to complete Tesla’s privatization.

After finishing the interview with Joe Rogan, Elon came back to the company and, while watching the stock price drop by over 10%, nonchalantly sent out an email to all employees.

The email talked about two things:

-

Progress in automotive production capacity and delivery

-

Restructuring of management

Here’s the original text of the email regarding Model 3:We are about to see the best performance in history (it seems like the word “Amazing” is not only favored by Steve Jobs and Tim Cook) for a quarter in terms of production and delivery of cars. The number of cars produced and delivered is more than twice that of Q2. We are creating the most exciting production capacity growth in automotive history. Even the Ford Model T, which set industry growth speed records, was not as fast in terms of production and delivery as the Model 3.

The key point of the first sentence is that the number of cars produced and delivered in Q3 is more than twice that of Q2. This goal, whether Elon saw it as a pie in the sky while the stock price plummeted or whether he had a clear plan in mind, is backed up by data.

Tesla’s Q3 revenue?

Tesla produced 53,339 cars in Q2, including 28,578 Model 3s, and delivered 40,740 cars, including 18,440 Model 3s.

This means that Elon said Tesla should produce at least 106,678 cars and deliver 81,480 cars in Q3, which means that Tesla is creating the first record of single-quarter production capacity of more than 100,000 cars in history.

Continuing on, the Model S/X sold a total of 21,800 vehicles in Q1 and 21,760 in Q2. Tesla stated in its Q1 and Q2 financial reports that the total goal for the two flagship models is to achieve a sales volume of 100,000 units for the full year.

(Ps: Since 2017, China has become Tesla’s largest market outside the United States. The Q2 financial report was released on August 1, 2019 when the trade war between the two countries was already in full swing. This is inevitably going to affect the sales performance of Model S/X in the Chinese market. However, Tesla has reiterated its guidance for annual sales of 100,000 units, and we look forward to seeing how Tesla will intelligently address this issue.)

What does 100,000 cars per year mean? This means that the quarterly sales volume of Model S/X must reach 28,220 vehicles.

So how many Model 3s will be delivered in Q3? 81,480 (total sales) – 28,220 (Model S/X) = 53,260 vehicles.

According to Inside EVs statistics, Model 3 delivered 14,250 and 17,800 vehicles in July and August, respectively. This means that Tesla needs to deliver 21,210 Model 3s in the last month of Q3.Continue, 21,210 cars/30 days = 707 cars, which means the Model 3 production capacity reaches 4,949 cars/week if the goal is achieved.

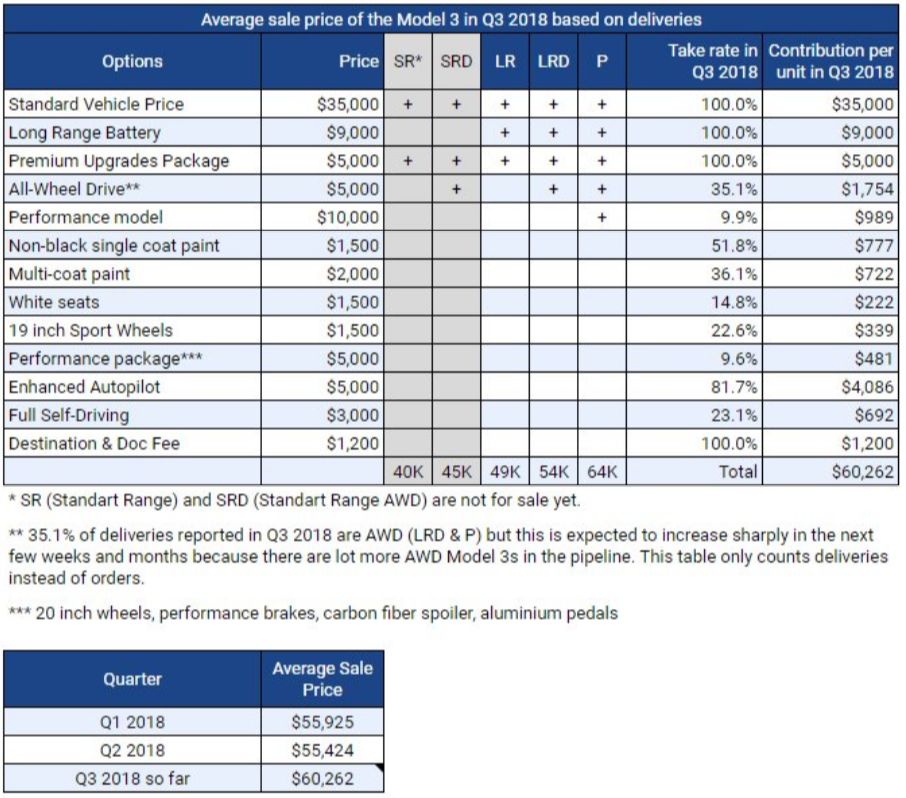

Speaking of average price, Teslike has studied most of the delivered Model 3 configuration sheets and found a new discovery: due to Tesla’s concentrated production of long-range all-wheel-drive and performance versions in Q3, the average price of Model 3 increased by $4,838 to $60,262 compared to Q2.

Yes, the Model 3, which promised to be the civilian car priced at $35,000, now has an average price of over $60,000. In fact, Tesla intentionally did this. In the Q2 financial report, Tesla clearly stated that the gross profit margin of Model 3 in Q3 would increase to 15%.

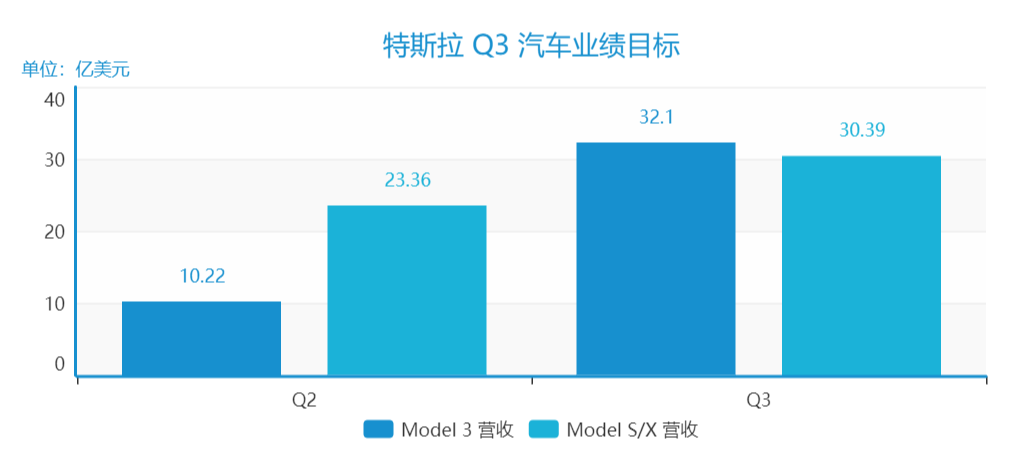

Automotive revenue, which was originally a key data in Tesla’s Q3 financial report, to be announced from October 25th to November 5th, can now be estimated. The average price of Model S/X remains unchanged, and sales have increased by 30%; The average price of Model 3 has increased nearly $5000, and sales have increased nearly three times.

Q2 Model 3 revenue: 55,424 × 18,440 = $1,022,018,560

Q3 Model 3 revenue: 60,262 × 53,260 = $3,209,554,120

Q2 Model S/X revenue: $3,357,681,000 – $1,022,018,560 = $2,335,662,350

Q3 Model S/X revenue: $2,335,662,350 × (28,220/21,760) = $3,029,062,110

Any new discoveries? Yes, the revenue of the single model of Model 3 will officially exceed the revenue of the flagship models of Model S/X in the third quarter.

According to this estimation, Tesla’s Q3 automotive revenue will be $6.249 billion, a year-on-year increase of 165% from $2.363 billion in Q3 last year, and a quarter-on-quarter increase of 86% from $3.357 billion in Q2 this year.## Speed up Production-Delivery with Bold Moves

With less than 20 days left until the end of Q3, can Tesla meet its production target of 4,949 units per week?

Tesla has a style of sprinting production at the end of each quarter, which has become a motive for short sellers to bet against the company. They claim that “Tesla’s end-of-quarter production is unsustainable.”

At the end of Q2, which was in late June, Model 3 production briefly surged to 5,000 units per week. Afterwards, Tesla stopped setting up new production lines, instead focusing on rationalizing and improving production efficiency of current lines. The goal is to reach a production capacity of 6,000 units per week by the end of August.

To maximize production and delivery, Tesla has launched a series of bold moves, such as cancelling two car paint colors, Metallic Silver and Obsidian Black. You might ask, what’s so difficult about painting a car?

On June 15, Elon sent out a company-wide email and specifically mentioned that the painting workshop of Model 3 needs thorough improvement and upgrading. Painting refers to the process of painting the white body from the welding workshop. It involves multiple steps such as cleaning, electrophoretic deposition, base coating, top coating, etc. It’s not that simple.

Tesla’s problem is that the efficiency issue of the two aforementioned car paints has not been solved. Order backlog is still high (at least 300,000 orders). So, Tesla prioritized delivery of orders with other car paint colors.

In addition, Tesla has begun testing a completely new production and delivery strategy. What strategy? Tesla will no longer produce Model 3 according to the order in which they were placed. Instead, they will produce based on a single, maximum production capacity strategy.

Before this, Tesla produced Model 3 in order of the order placements. But each customer’s configuration is different. Model S has 7 car paint colors, 5 interior options, 3 wheel options… At most, there were 1,500 configuration options. Model 3 has compressed the configuration options to 100. However, recently, Tesla only produces configuration options that enable maximum production capacity.

To put it simply, Tesla produces a batch of customized cars with same configurations and then emails reservation holders about the delivery notification.We now have a limited number of Model 3 available for immediate delivery. As pre-order customers who placed orders on launch day, you are invited to be the first to take delivery on a first-come, first-served basis. Tomorrow, we will send this invitation to other pre-order customers (verbatim from email).

The most amazing thing is that this large-scale delivery ceremony was held at the Tesla factory and even skipped the step of shipping to Tesla’s delivery centers around the country, making it the fastest production and delivery speed in history.

Why adopt such extreme measures? In fact, production and delivery are two different concepts. Tesla’s production volume at the end of Q2 exceeded its delivery volume, with as many as 11,166 Model 3 and 3,892 Model S/X “in transit.” This strategy is an attempt to reduce the “in transit” space and bring production closer to sales.

What I mean is that with this multi-pronged approach, it should be no surprise that the 4,949 vehicles per week sales goal has been met by the end of September.

This is probably…the confidence behind Elon’s vaporization of $16 billion in market capitalization.

Making nice with Wall Street

However (Whenever there’s a “but,” there’s never anything good, right?), two high-level executives have recently left Tesla, and Elon has been in great pain for the past year. If the stock price is to take off, Wall Street must be given a solution.

Below is the reorganization of management mentioned in the email:

Promoting Jerome Guillen, the head of the electric semi-trailer truck project, to President of Automotive Operations, responsible for overseeing all automotive operations and project management and coordinating the automotive supply chain.

Jerome and Tesla CFO Deepak Ahuja are the only two executives who have left Tesla and returned, and are considered “battle-tested Tesla warriors.” He opened the semi-truck and Roadster 2 unveiling event, followed by Elon’s appearance.

Jerome was originally the truck project manager at Daimler and his first project at Tesla was the Model S. He later served as Tesla’s global vehicle engineering director and executive vice president of sales and services.Translate the following markdown text in Chinese to English markdown text, in a professional manner, keeping HTML tags inside Markdown, and only output the results

But that’s not all. After the departure of Model 3’s chief engineer, Doug Field, Elon asked Jerome to take over the Model 3 project. Within weeks, Jerome built a highly technical final assembly line. His engineering talent and ability to handle pressure are not to be underestimated.

My understanding is that Jerome’s new title is actually COO. Responsibilities of the core five are as follows:

-

Elon focuses on solving R&D, design, and engineering challenges across all product lines.

-

Automotive President, Jerome Guillen, is responsible for the entire automotive business.

-

CTO JB Straubel is responsible for operating and project managing all automotive product lines, the Energy business, and supply chain management.

-

CFO Deepak Ahuja is in charge of managing all revenue and expenses.

-

Chief designer Franz von Holzhausen is responsible for the design work of all product lines.

Wouldn’t the stock price take off now?

One more thing

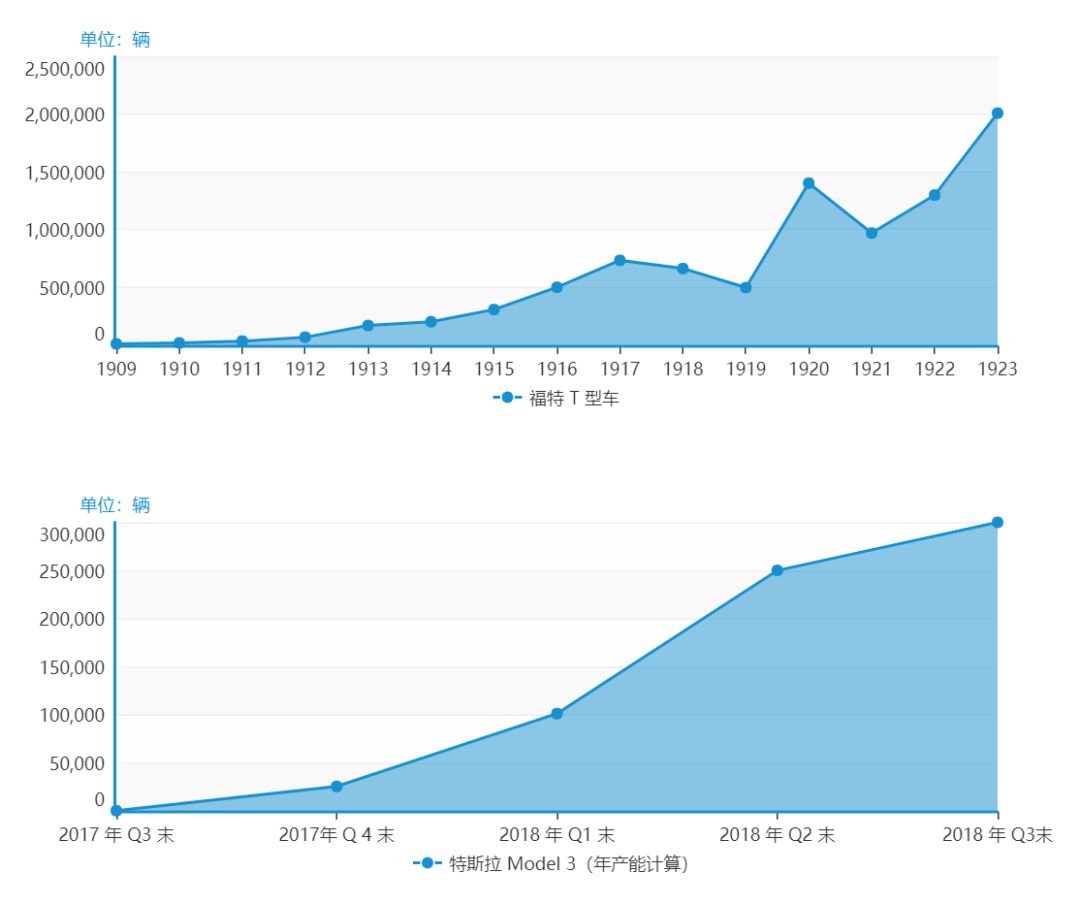

Starting with Q1 earnings reports, every time Tesla mentions Model 3’s production capacity, they take a moment to criticize the Ford Model T. The Ford Model T is undoubtedly one of the greatest cars of all time, selling 14.68 million units during its lifecycle. How fast did its production capacity grow? Compared to Model 3?

A picture is worth a thousand words:

Okay, this graph isn’t quite good enough. Let me summarize: It took one year for Tesla Model 3 to increase its production capacity from 0 to 300,000 units/year, while it took the Ford Model T six years.

So don’t worry, Model 3, you at least have two more years in the “fastest-growing production capacity model” chair. But why only two years?

Because in two years, the Model Y should be in production.

-

Elon Musk’s Open Letter to Investors: Tesla Will Not Be Privatized

-

Tesla Will Not Be Delisted, Here’s What You Should Really Be Worried About

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.