On August 31st, WM Motor launched a workshop based on its three-electric system at the Chengdu International Auto Show. Considering the recent doubts about WM Motor’s batteries, this kind of sermon was very necessary and timely.

Before presenting the key points of the workshop, it is necessary to talk about WM Motor itself. Among the top new car companies, WM Motor is an anomaly. Unlike most of the new car companies that are slightly ahead today, WM Motor is the only one with a very heavy traditional car company gene, from its founding team to the whole company.

A year ago, this was considered one of the potential risks in WM Motor’s future development process, as WM Motor might become a very “traditional” new car company due to a lack of understanding of smart connectivity and operational users. However, when it comes to delivery in the second half of this year, even NIO, who spent the most investment in the early stages and had the most intensive deployment, still experienced about a month’s delay in delivery.

At least from the outside, even the Internet car-makers who paid the most attention to the manufacturing process in the early stages still underestimated the difficulty of estimating the manufacturing and supply chain management. Yu Jingmin, the vice president of SAIC Passenger Cars, recently joked that “If you want Li Bin to say that he is more reliable than SAIC in car making, he would be embarrassed” – when the voice of respect for manufacturing is heard again, WM Motor’s manufacturing genes have again dramatically shifted from subtraction items to bonus items.

The “reliable” image of WM Motor also has trouble.

On May 14th, online exposure showed that a pure electric car, the YEMA U PRO, caught fire in Sichuan province. YEMA’s battery supplier, Gu Shen Corporation, is actually one of WM Motor’s four suppliers. Some netizens suspected the reliability of WM Motor’s batteries because of this.

This kind of straightforward thinking is not appropriate. A simple example is Panasonic, which not only cooperates with Tesla to build its battery factory, but also is the power battery supplier for Volkswagen and Toyota. Considering that Tesla cars have caught fire several times, can we think that the reliability of Volkswagen and Toyota’s pure electric cars is worrying?

The core components of a battery roughly include the battery cell, module, pack, BMS, and thermal management, etc. Different car companies conduct independent research and development on different specifications of the same battery cell. The safety and reliability of the pack is the true embodiment of a car company’s technical capabilities.

WM Motor should have preached about their technical capabilities first, but for some reason, this technical explanation about the three-electric system did not launch until mid-August. Regardless, let’s take a closer look at WM Motor’s three-electric technical capabilities.First of all, in terms of R&D, WM’s R&D team has reached more than 500 people, and 80% of the technology experts and mid-level management personnel are from General Motors, Faurecia and other companies. WM’s R&D process and product quality are benchmarked against GM’s GVDP vehicle development process.

Regarding the details of the R&D process, the following are all taken from WM’s announcement:

R&D certification system: WM has established a comprehensive test certification system (WTCS-WM Test Certification System), covering 9 major verification areas such as “Power Battery System”, “Chassis”, “Safety”, “NVH”, “Electronics and Electrical Appliances”, “Internal and External Decoration of the Body”, “Automatic Driving”, “Intelligent System” etc., with 120 vehicle-level tests, 3,400 system-level tests, and over 14,000 component-level tests, including 3,000 tests related to the power battery system.

Vehicle performance targets: 15 major items (weight and center of gravity, power and economy, handling and steering smoothness, braking, NVH, environmental protection, thermal management, air conditioning performance, vehicle size and human-machine engineering, reliability and durability, electronics and electrical appliance performance, safety performance, environmental adaptability, sealing, maintainability), 196 sub-items, 762 small items.

Test process: WM’s first mass-produced model EX5 has undergone multiple rounds of joint driving and performance testing, 2 rounds of summer high-temperature road testing, 3 rounds of cold weather testing (including a low temperature environmental cabin of -40°C and road testing at -20 to -42°C), multiple rounds of vehicle range calibration and diagnostic calibration, and more than 400 test vehicles have been put into testing, with a cumulative test mileage of more than 3 million kilometers and a cumulative test work time of about 100,000 hours.

By showcasing all these complex tests, WM is trying to suggest that despite being a new car company, it has invested massive efforts in various performance indicators verification, including safety and reliability, and fully benchmark traditional automakers or even surpass them.

In my limited participation in electric powertrain technology workshops at car companies, companies similar to WM that have shown large and complex testing systems to ensure product reliability includes BMW’s battery department and GM China Battery Research Center.

If WM’s allegations are true, then its traditional genes have indeed benefited the company in the R&D process.

However, it’s quite embarrassing that on August 25, around 2 pm, a WM EX5 caught fire due to a short circuit at the Chengdu Research Institute. Relevant pictures circulated online and sparked heated discussions.

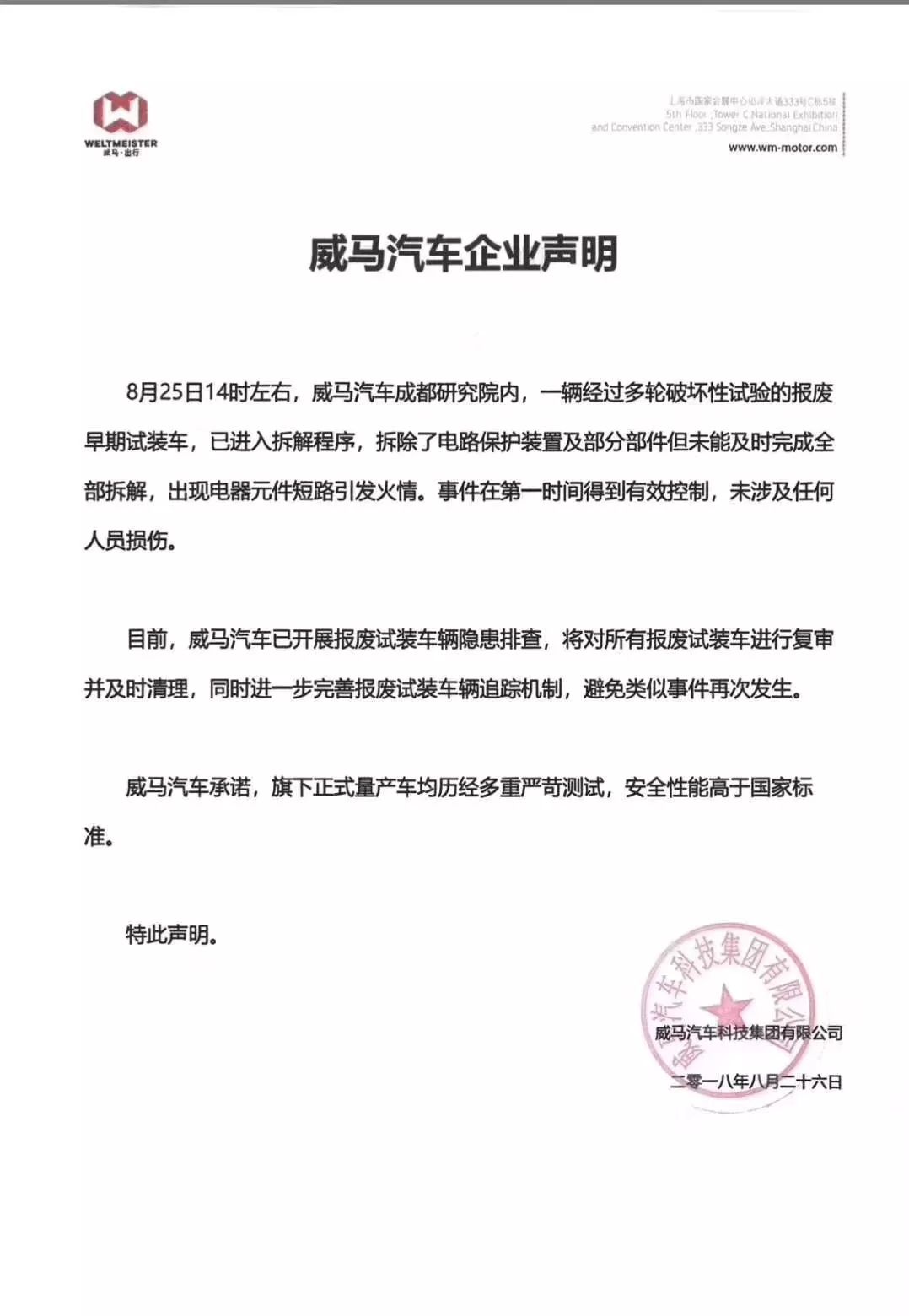

On August 26th, WM issued a statement clarifying that the burning model was a scrapped trial installation vehicle, and the officially mass-produced cars have “safety performance higher than the national standard.”

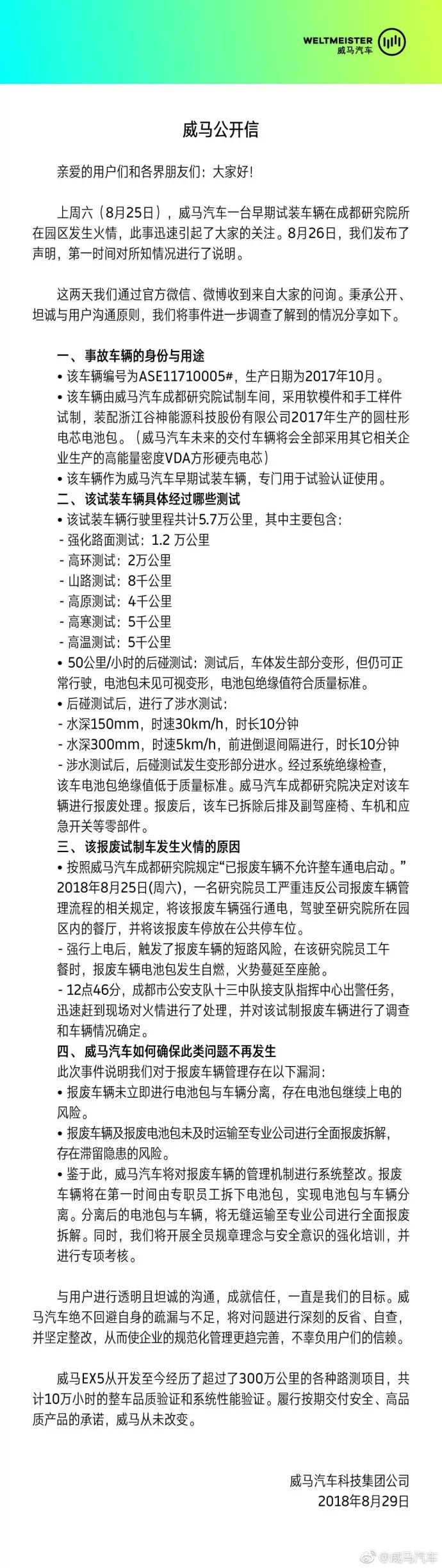

However, due to insufficient explanation of the accident details, the safety concerns of WmAuto EX5 owners were not appeased. On August 29th, WmAuto issued another open letter to users, providing comprehensive and detailed explanations about the identification and use of the accident vehicle, the testing process, the cause of the fire, and the follow-up improvement mechanism.

WmAuto stated that the accident vehicle was equipped with GuShen’s cylindrical battery cells and said that “all future delivery vehicles of WmAuto will use high-energy density VDA square hard-shell battery cells produced by other related companies”.

In other words, whether it is a B-end or C-end model, WmAuto will no longer use battery cells from GuShen.

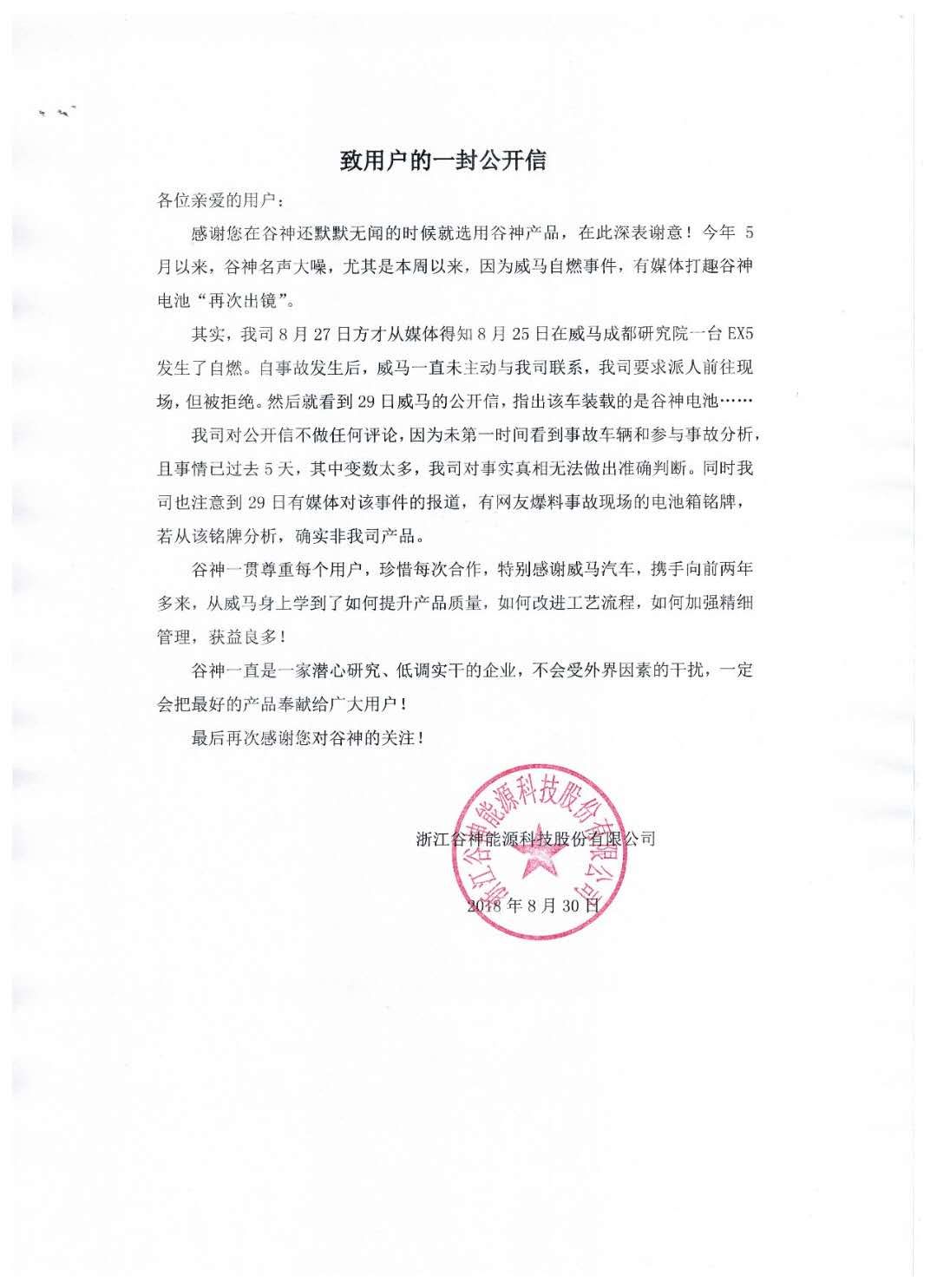

On August 30th, GuShen released an open letter to users, questioning WmAuto’s refusal to send people to the accident site to participate in the accident analysis and suggesting that the authenticity of the accident vehicle being equipped with GuShen battery cells is doubtful.

However, due to the severe damage of the accident vehicle, the truth of the incident cannot be verified.

Let’s review WmAuto’s crisis PR mechanism:

-

One day after the accident vehicle was exposed, WmAuto issued an unqualified statement;

-

Four days after the accident vehicle was exposed, WmAuto issued a comprehensive statement;

-

Five days after the accident vehicle was exposed, GuShen was dissatisfied and sent a letter questioning WmAuto, which reduced the credibility of WmAuto’s second statement.

In fact, compared with traditional car companies, WmAuto’s decision-making and execution mechanism was not bad with a detailed statement provided four days after the accident vehicle was exposed. However, as a new car manufacturer, since the target group is aimed at younger Internet users who are more likely to accept new energy vehicles and love technology, WmAuto has to learn the mechanisms used by Internet companies to operate users, including effective interaction with users, timely feedback on user suggestions, and quick and comprehensive communication with users during PR crises.

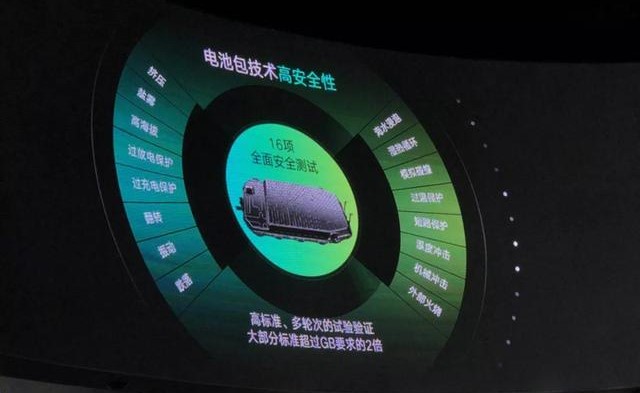

WmAuto also specifically explained the testing mechanism for the safety of battery packs in the workshop:

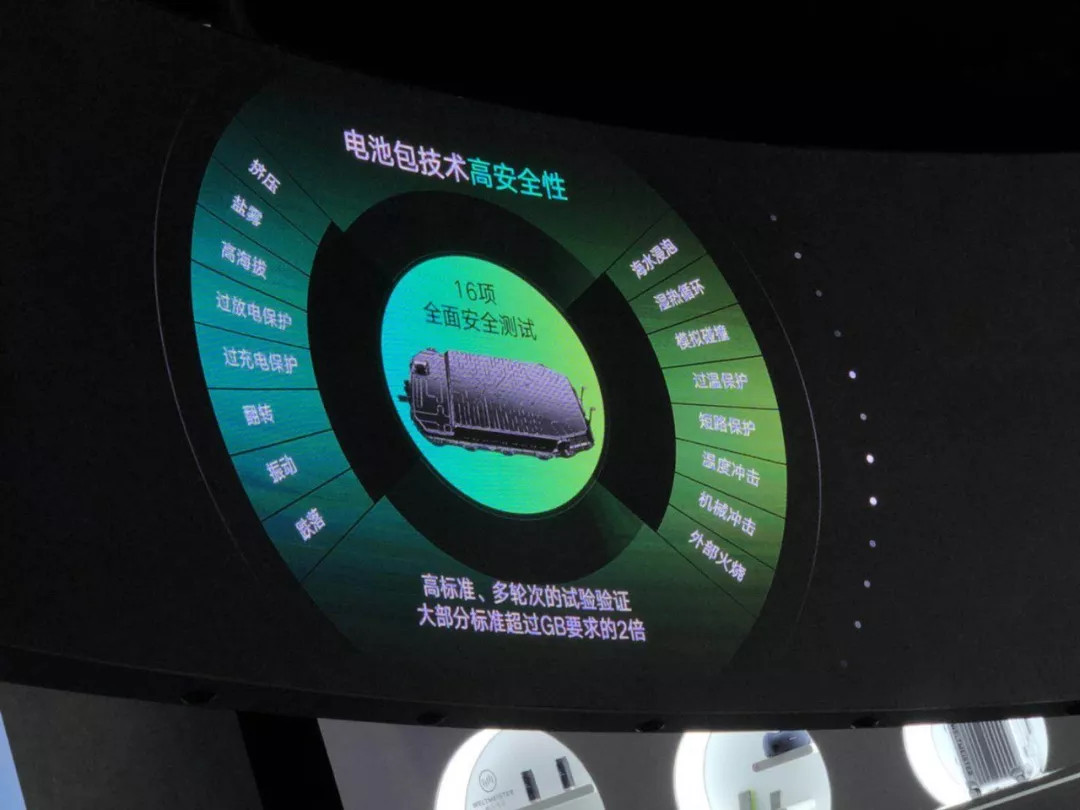

High Security: High standard and multiple rounds of testing, with most standards exceeding national standards by twice. The 16 comprehensive safety tests (vibration, compression, external burning, seawater immersion, over-discharge protection, overcharge protection, falling, mechanical shock, temperature shock, short circuit protection, over-temperature protection, simulated collision, thermal cycling, high altitude, salt spray, and flipping) were all passed in one go.

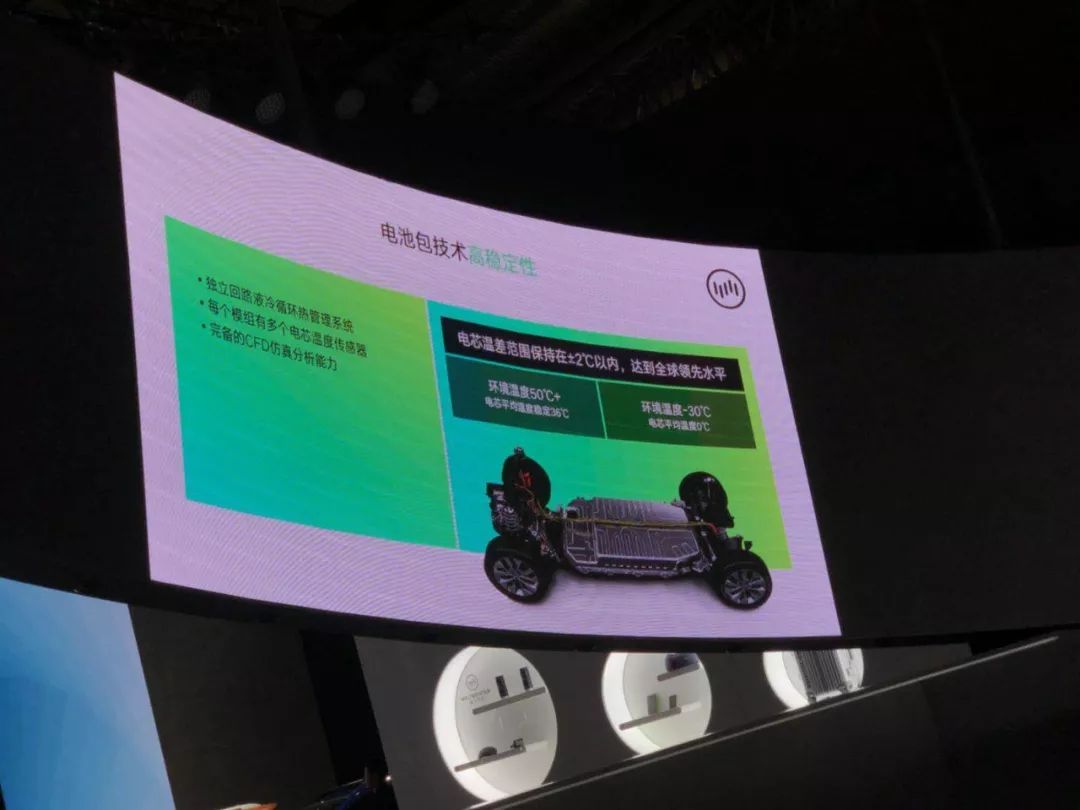

High Stability: Equipped with WM’s independently developed active constant-temperature battery thermal management technology, which adopts independent liquid cooling circulation, and each battery module has two core temperature sensors. The cores can be kept within the temperature difference range of ±2℃, ensuring consistent core performance and improving the battery system’s cycle life.

WM’s car fire is not false, but I cautiously believe that everyone’s attention has been diverted by the accident car. For WM, the research and development and manufacturing system built by a team from a traditional car company, the safety and reliability of the battery are not worth excessive worry. On the contrary, the response mechanism exposed in this PR crisis and the shortcomings of the industry’s insufficient “newness” for WM as a new car manufacturer and insufficient attention to intelligence, are the issues that WM, investors and users should focus on.

- Nio Goes Left, WM Goes Right|The Path to Success Beyond Tesla* Is the electric vehicle era coming earlier with the WmAuto EX5 priced from 99,000 yuan?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.