Each of NIO’s publicity events cannot do without discussing technology, and this time the theme was the “three electric systems.”

On July 27th, NIO held a brand experience day centered around the “three electric systems” technology. Aside from displaying battery and motor components on site, the relevant leaders of the three electric systems department also came to the site and engaged in comprehensive technical explanations. This is an extremely rare occurrence in new car companies, giving a feeling of falling into a professional technical forum.

Why talk about the “three electric systems”?

Over the past decade, the development of electric vehicles has moved from the embryonic phase into the early stages of promotion, experiencing two to three generations of product iterations. However, even so, looking globally, the technological development of new energy vehicles still hasn’t entered the mature application stage of the “three electric systems” strategy.

For instance, from the perspective of the charging strategy, there are still models that do not support three-phase AC electricity or do not have a fast charging interface; from the perspective of thermal management strategy, there are still models that use the passive cooling method of natural cooling; from the perspective of the BMS strategy, there are still many manufacturers that hang the self-developed title yet entirely use the supplier’s solutions.

In fact, the new energy vehicle market faces increasingly fierce competition, and the requirement of system integration is higher than ever. The strategy of mainly integrating supplier solutions is slowly becoming unsuitable for the market’s development needs. Traditional car companies are continuously increasing the R&D investment in the “three electric systems” field, especially the power battery field. The integrated development ability of software and hardware will also become the core technology ability for future car companies’ competition.

NIO’s Three Years

NIO was founded in July 2015, and it has been precisely three years since then. What things can be accomplished in the three years regarding the “three electric systems”?

First, take a look at some data:

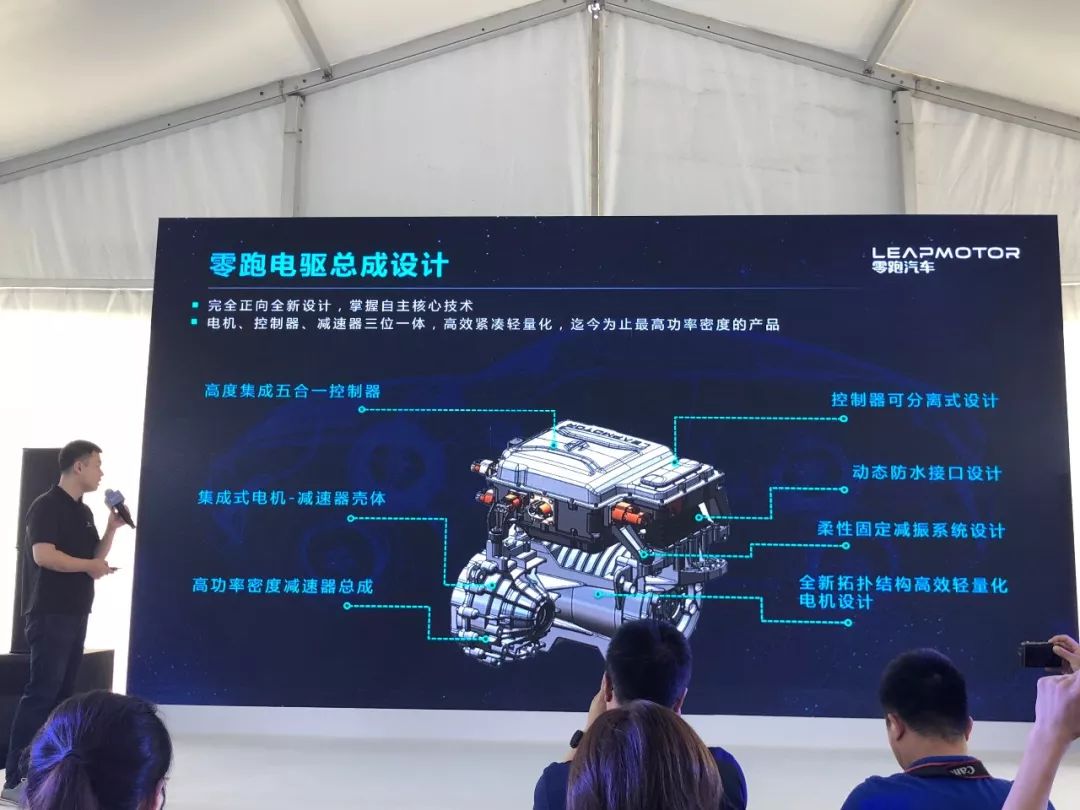

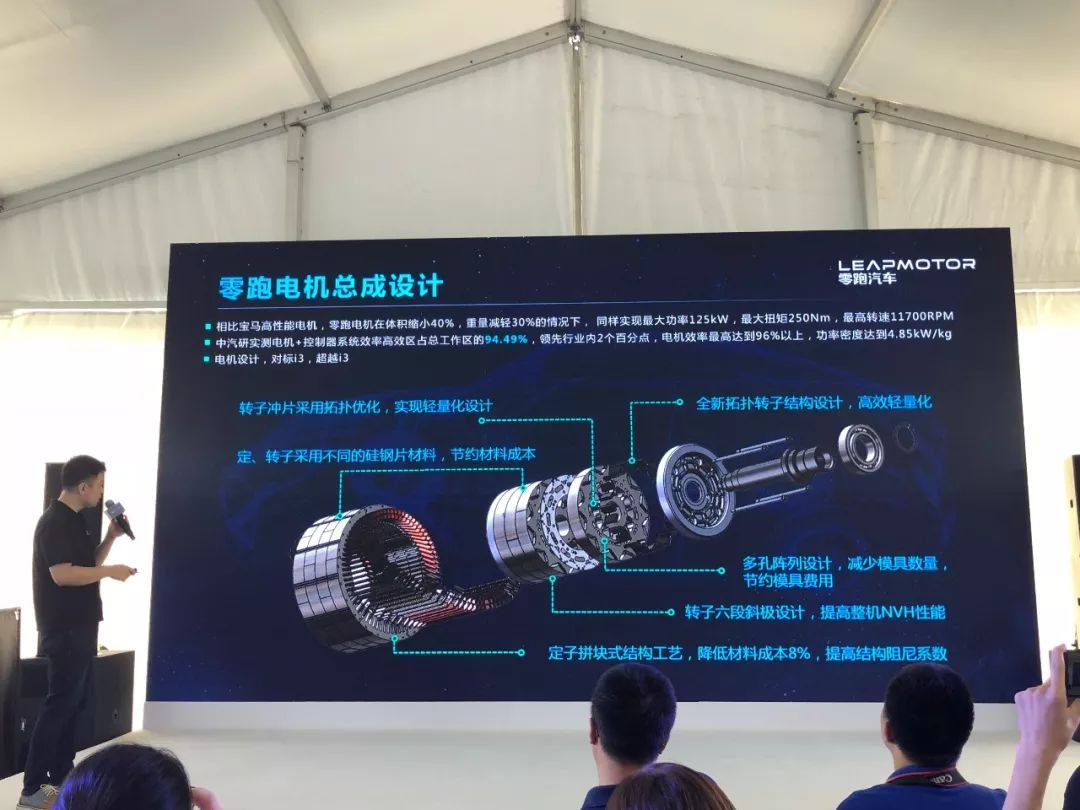

1) NIO released the electric drive assembly with the codename “Heracles” (named after Heracles, the Greek mythological god of power), weighing 91 kg overall, with a maximum power of 125 kW, peak torque of 250 Nm, a maximum speed of 11,700 RPM, a 94.49% high efficiency zone ratio measured by CATARC, a 93.6% system efficiency, and a power density of 4.85 kW/kg.

2) The gearbox can withstand a maximum speed of 13,000 RPM, peak torque of 280 Nm, and torque density of 12.82 Nm/kg.

3) The energy density of the 18650 power battery system reaches 140 Wh/kg, and its discharge efficiency reaches 97.7%. The thermal management system controls the maximum temperature difference at approximately 1.5°C.

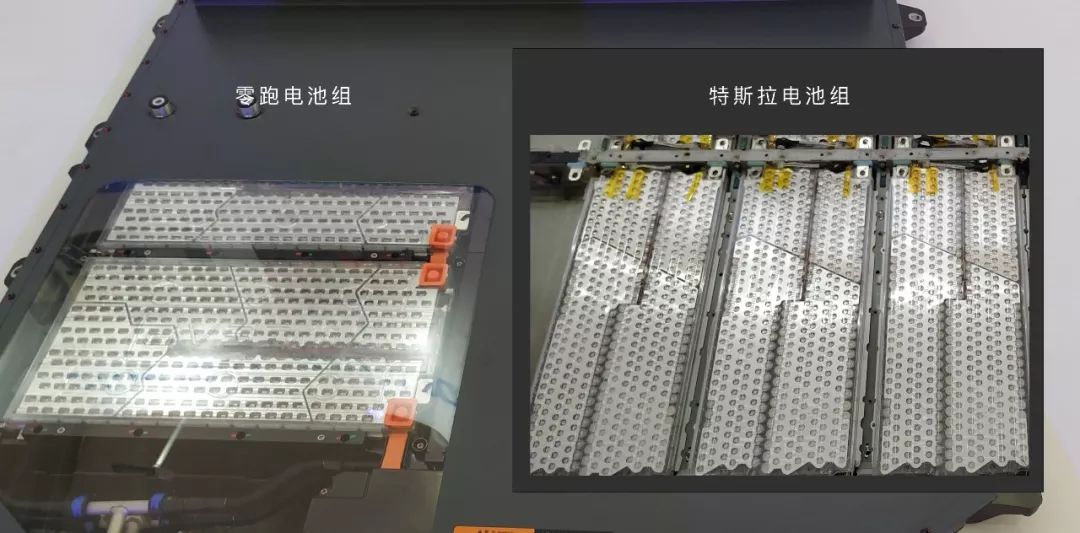

4) NIO’s self-developed battery pack’s system energy density surpasses Tesla’s structural method by 15%. For example, adopting NIO’s self-developed 21700 battery pack structure can achieve 46 kWh, while using Tesla’s battery pack structure can only reach 40 kWh.5) In the BMS strategy, the SoC accuracy reaches 3%, the normal temperature discharge efficiency reaches 97.7%, and the low temperature (-15℃) discharge efficiency is 92.5%.

The key points here are that LI’s three-electricity components are mainly self-developed. For example, in terms of power battery, LI independently developed all components except the battery cells, including power battery module, Pack, BMS hardware and software, and so on.

Song Yining, the director of LI’s power battery, said that this is the highest level of self-developed battery pack technology in domestic automakers except for BYD. Song Yining had previously worked for BYD and Johnson Controls and had years of profound experience in power battery research. He led his team to develop high and low matching schemes for 18650 and 21700 battery packs for LI.

Currently, the domestic cylindrical cell battery suppliers with the highest shipment volume are BAK and Lishen. LI’s 18650 battery cell is from BAK, while the 21700 battery cell is from Lishen. According to market data for Q1 2018, the installation rate of cylindrical batteries in the EV passenger vehicle market reached 19%, while the installation rate of soft-pack batteries was only 8.5%. The battery type with the largest sales proportion was the square battery, with an installation rate of 72.4%.

The shipment volume of cylindrical cell batteries is not as low as imagined, and other car manufacturers such as JAC and Haima also use cylindrical cell batteries. But when it comes to the design of the cylindrical cell battery pack, the number of involved suppliers is relatively small. Therefore, LI has no chance to take the supplier’s solutions and dress it up as a self-developed technology. Moreover, more details about battery pack development were also disclosed on site.

When it comes to the selection of cylindrical battery cells, Song Yining explained two reasons. One is that LI’s first model, the S01, has a low chassis, and the height of the battery pack must be effectively controlled. The final thickness of the power battery pack is controlled to be around 90 mm, which is suitable for the selection of two types of cylindrical battery cells.

The other reason is that in 2015, when LI began developing its three-electricity system, the safety and consistency of ternary square battery cells were not sufficient to meet the design requirements of LI’s three-electricity system. Song Yining believed that 18650 technology is almost the most mature at that time.

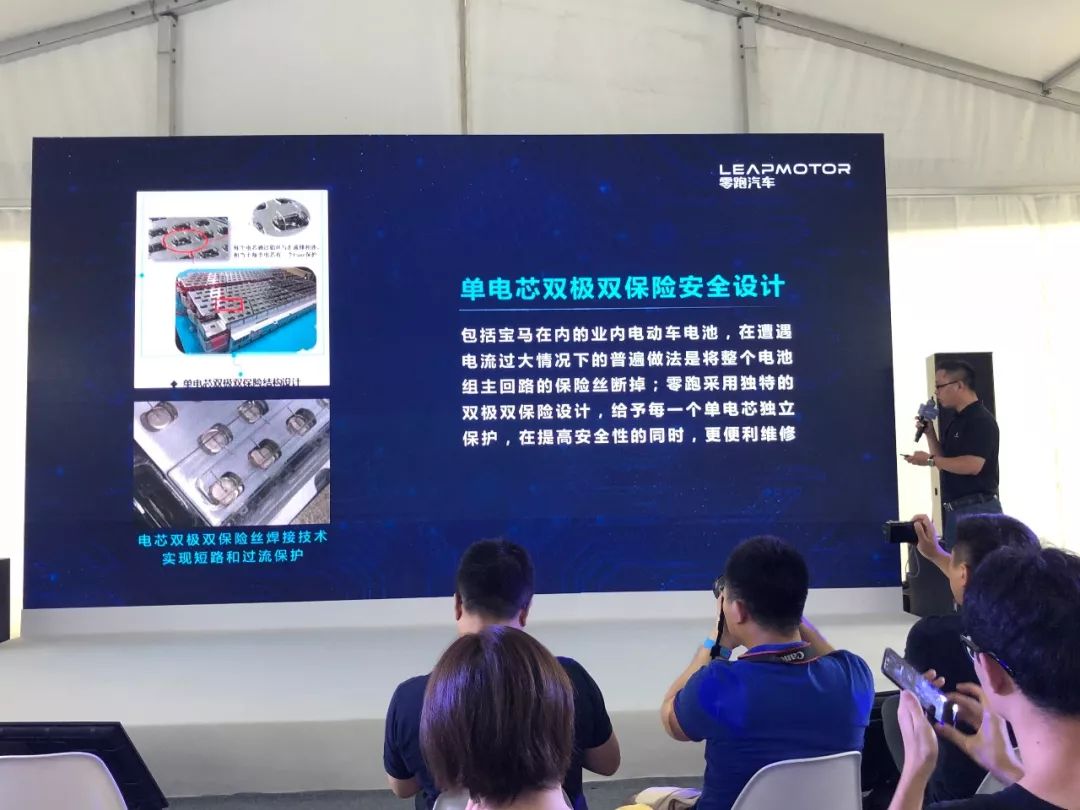

Regarding the safety design issue that may involve electric vehicle fires, the common industry practice is to fuse the main circuit fuse of the battery pack when the current is too large. However, LI chose a single-cell dual-pole double-protection structural design to provide double protection for the battery cells. In addition, all live leakage parts are isolated, and hardware isolation is performed between each module using cross beams to fully prevent battery pack short circuits. LI has applied for a patent for this.

As for the thermal management solution for the battery pack, LI (Leapmotor) uses a solution similar to Tesla’s – a serpentine liquid cooling system to control the temperature difference within 1.5 ℃.

Facing the issue of energy density of the battery pack system exceeding Tesla’s, Song Yining explained that they adjusted the gap between each unit cell to be smaller, and made the cooling pipeline more sophisticated, allowing more unit cells to be installed in the same volume.

In addition to the battery, LI’s electric drive assembly is a three-in-one design of motor, controller, and reducer, currently leading the industry in terms of integration.

Comparatively, BorgWarner’s iDM (Integrated Drive Module), which also integrates the reducer, motor and controller, is still in the development stage, and is set to be mass-produced only in 2020. Currently, many car brands choose BorgWarner’s eDM (Electric Drive Module) which only integrates an eGearDrive transmission and motor. In BorgWarner’s integrated system, the motor comes from the US-based Remy Electric Motors, and the control comes from the UK-based firm Sevcon.

Through the use of a 91 kg electric drive assembly, LI achieves 96% maximum efficiency of the motor, reaching maximum power of 125 kW and peak torque of 250 N.m.Why can the NIO do all these things? Let’s take a look at the team size and patent numbers:

1) NIO’s electronic control team has over 50 R&D personnel, with more than 30 patents filed cumulatively, of which 10 invention patents are from the field of electronic control algorithms;

2) The core members of NIO’s battery team are from BMW, BYD, and DENZA. They have filed a total of 36 patents, including 9 invention patents for Pack systems and 7 invention patents for BMS systems;

3) The size of NIO’s autonomous driving team is around 40-50 people, with Dahua Shares’ 400-person algorithm team as technical support.

The first model S01 of NIO, which will be launched in Q1 2019, will be equipped with the L2.5 assisted driving system. Later, this model will also achieve L3 level through remote upgrade, which means that S01 has reached the full car OTA standard.

When attending NIO’s first event, NIO’s founder and chairman, William Li, introduced that NIO achieved independent research and development of three vehicle platforms, three electric systems, intelligent network systems, and autonomous driving systems, which took 34 months to accomplish.

Without enough technical evidence, this sentence is hard to convince people. However, it seems true now.* NIO: Is it the Sweeper in China’s Autonomous Vehicle Field?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.