What is “The shorter the news, the bigger the thing?” 7 days, 7000 cars, Tesla team ❤️.

The 5000 Vehicles per Week We’ve been Aching for

The last week of each quarter is always a crucial moment for Tesla to verify the sustainability of their latest production capacity. However, it seems that the last week of Q2 2018 was unusually easy for Tesla.

On June 25th, John Totah, the Tesla Model 3 Material Transfer Manager, exposed on Twitter: We missed 2500/week in March, but we’ve now nailed 5000/week for Q2.

John Totah quickly deleted that tweet. However, as a Twitter superstar, if Tesla CEO Elon Musk had accomplished the production goal ahead of schedule, he would not be more restrained than John Totah.

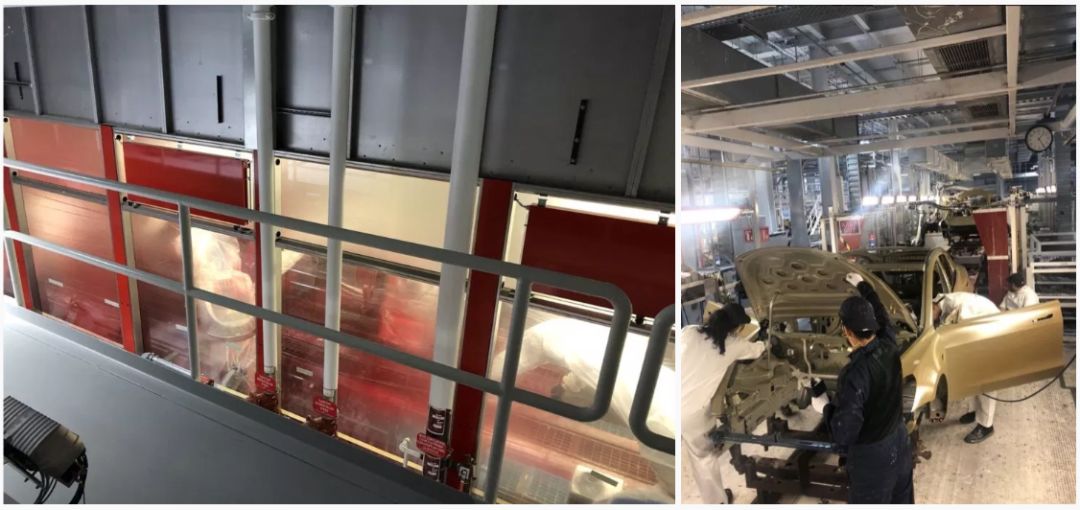

So I went to Elon’s Twitter to observe, until now, there have been only two photos related to Model 3’s powertrain and paint shop operation……

On the 29th, Tesla opened the option configuration for Model 3 reservation owners in the U.S. and Canada. (After confirming the configuration, the factory will schedule production, and the car can be delivered in about four weeks.)

On June 28th, Elon’s 47th birthday, he specifically tweeted, “Thank you for all the wonderful wishes. This is the first birthday I’ve spent in the factory, but in a way, it’s the best one.”During this time, he also chatted with netizens about the necessity of space civilization, the creativity of Tesla’s Cybertruck, and the recycling of SpaceX’s Falcon 9 rocket…

In summary: He strongly hinted at the breakthrough of Model 3 production capacity, but not only did he not say it, but also pretended not to care.

On July 1st, Tesla employees revealed the signature of the Model 3 5K CLUB, and then Elon issued the Twitter post at the beginning of the article, announcing the achievement of Q2 production capacity target.

Elon and the media confront each other again

Isn’t it scheming for Elon to actually announce 7000 Model 3s per week on Twitter, considering the actual production capacity of 5000 vehicles per week and an additional 2000 Model S/X?

Actually, Elon was dissing the media again.

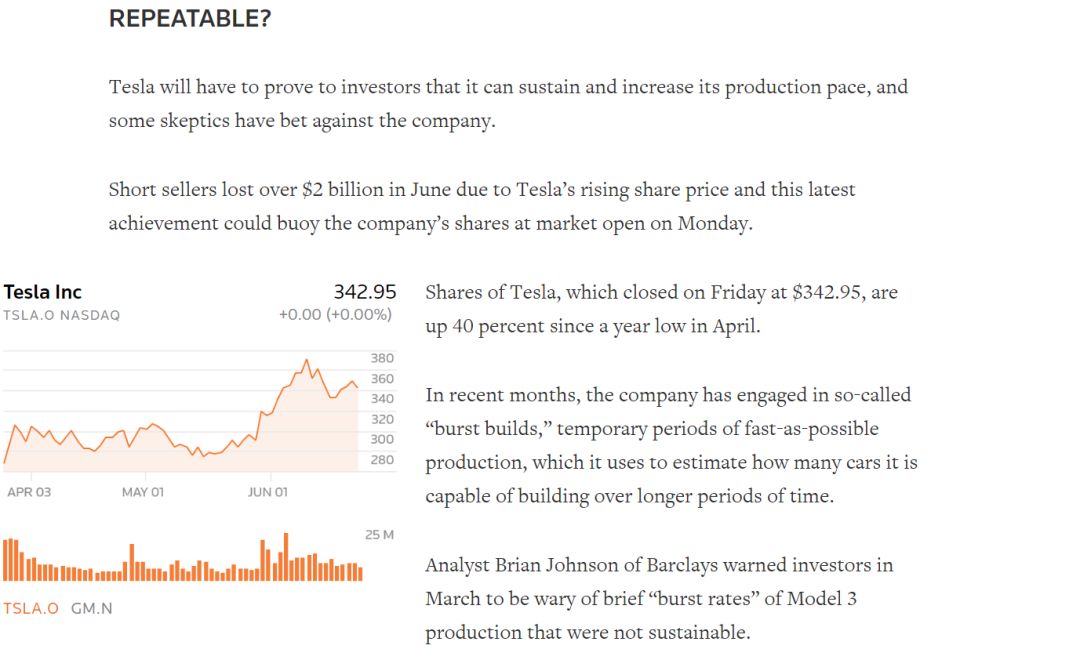

On June 29th, Reuters published an article in which they interviewed “3 Tesla Fremont factory workers”. According to the workers’ revelations, the Model 3 production line has been running continuously 7×24 hours. However, in the last week, only 210 and 305 Model 3s were produced in the first 12 hours of Monday and Wednesday, respectively. Even if the estimation of 300 vehicles/12 hours were used, the capacity would only be 4200 vehicles per week.

Today, Reuters published another article, questioning the sustainability of Model 3 production capacity in detail. Reuters quoted Barclay analyst Brian Johnson’s warning to investors that “Model 3’s short-term production capacity is simply unsustainable.” One worker revealed that, in order to achieve production capacity, employees from other departments were sent to the Model 3 production line, and management required “the workers to rest while the machines continued to work.” Some departments were even closed to assist the Model 3 production line, such as the Model S production line.

Reuters’ conclusion is that this typical robbing-Peter-to-pay-Paul type of growth doesn’t match Elon’s previous promise of increasing production capacity through a fully automated production line.

Elon’s announcement of 7000 Model S/X/3 vehicles in 7 days is his response to this, indicating that production capacity has been achieved.Besides, both Reuters and The New York Times’ long articles mentioned Tesla’s problem of setting up the Model 3 general assembly line in the newly established giant tent. An automotive manufacturing expert interviewed by The New York Times commented that adding a new production line in the automotive industry in an emergency is a “rare and risky” practice, and the quality control of Model 3 is worrying since the production line was established in haste without testing.

As expected, Elon responded sharply in the email sent to employees stating, “Through sheer force of will and creativity, we have developed a brand new solution that nobody else in the world would have considered. We fought like crazy to make it work. And we’re proud to say that we’ve completed the production increase to 5,000 Model 3s per week, whatever.”

Regarding sustainability, the email specifically mentioned at the end that with the general increase in the overall capacity of Tesla and the continuous improvement of new production lines, we expect the Model 3 production capacity to reach 6,000 units per week next month.

Is this real or just empty talk? Tesla’s exclusive battery partner, Panasonic, provided a boost: Yoshihiko Ito, head of Panasonic’s automotive business, said at a shareholder meeting that “with the rapid improvement in production capacity of Model 3, occasionally there may be insufficient battery supply.” Panasonic may consider additional investments in the Tesla Gigafactory 1 project.

What does 5,000 units per week mean?

For Tesla, achieving a production rate of 5,000 units per week was not an easy result to obtain. First of all, it should be pointed out that at the end of Q1, Model 3 production capacity was only 2,000 units per week, and the target of 2,500 units per week was not achieved. Therefore, to achieve the Q2 target as planned means that Tesla’s manufacturing team has to pay a bigger price than in Q1.

Throughout Q2, Tesla also had to face many major events that negatively impacted production capacity improvement:

-

On May 7th, Elon issued a company-wide email to initiate a major restructuring of the supplier system, removing all unnecessary suppliers.

-

After May 25, Tesla announced the appointment of 11 new executives (executive turnover).

-

On June 12th, Tesla announced a reduction of 9% of its workforce, with a total of 4,000 employees leaving.

-

On June 17/18, Tesla was hit by insider incidents, its factory caught fire for no reason, and the production line was forced to shut down.

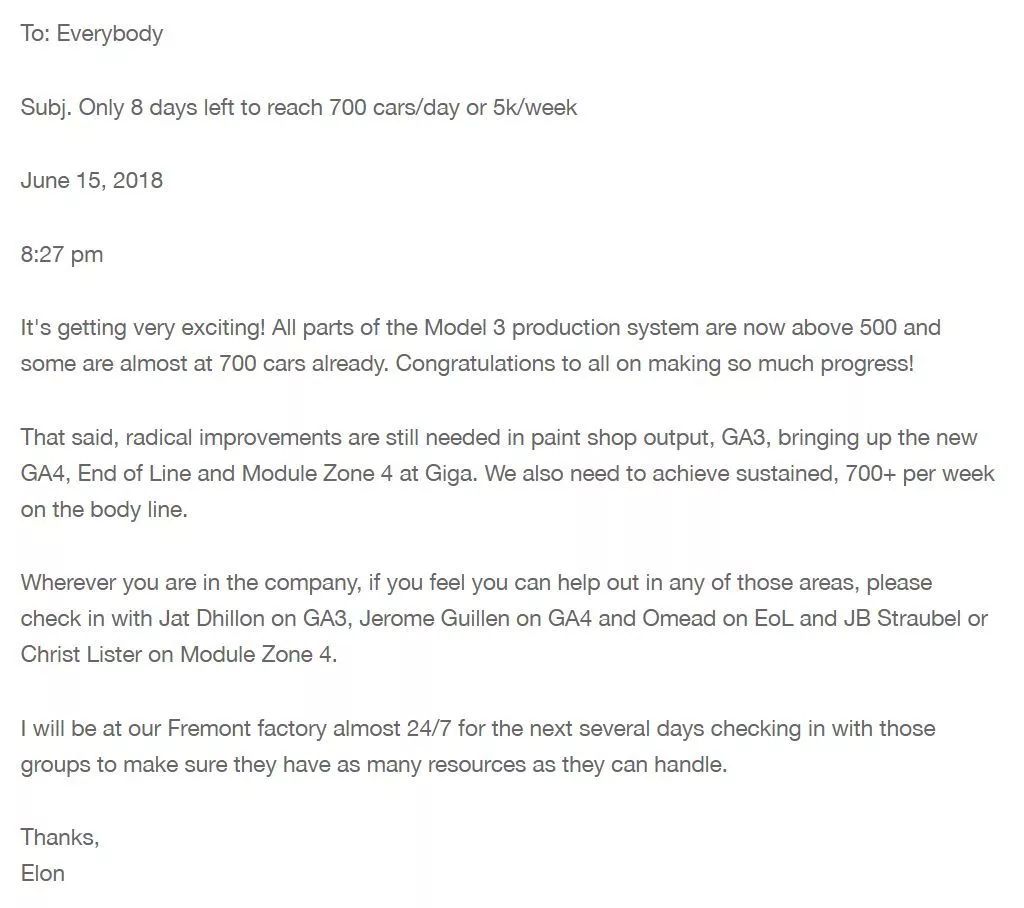

On June 15, Elon sent an email to all employees, inspiring them to sprint toward Q2 production capacity targets. In that email, we learned for the first time that there were bottlenecks in the Model 3 production capacity improvement process, including painting process, #3 final assembly line, newly added #4 final assembly line, end of production line, welding process, and battery module production line’s 4th station.

Elon specifically pointed out that the painting process needed “thorough improvement and enhancement,” which is why he shared photos of the painting workshop on Instagram, probably because the new process has met his expectations.

Note the timing of the email, June 15, and subtract the 7 days needed to confirm the sustainability of production capacity, which means that in the short 8-day period, Tesla overcame so many obstacles and increased its production capacity from 3,500 vehicles/week to 5,000 vehicles/week.

It seems that the management team slept at the factory to watch the production capacity, and the effect was immediate.

At the end of today’s email, Elon said we have finally become a real car company. This sentence has two meanings. The first is a significant increase in Model 3 production capacity, which has allowed Tesla to remove the hat of a small luxury automaker and begin to move toward large automakers. The other point is more critical: Tesla will finally become profitable.

Starting from the Q1 earnings conference, Elon mentioned in various public occasions that Tesla will soon make a profit. There are no exceptions to the long-range version, dual-motor version, and high-performance version that have already been delivered, and they are all high-profit models in the Model 3 product line. Coupled with Model S/X’s long-term stable high-profit margin of over 25%, it is expected that Tesla’s profits will be within reach by no later than Q3 or Q4.

Finally, let’s talk about the impact on the entire industry: The Q1 delivery report stated that if this growth rate can continue, the Model 3’s production capacity growth rate will surpass the first mass-produced car Ford T, which set a record for modern automotive industry growth.

The problem now is that the Q2 production capacity growth rate is obviously faster than Q1…Of course, for car owners who have not yet received their vehicles, they still hope that Tesla’s management team will continue to closely unite around Comrade Ma Yilong in the future and continue to make progress.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.