Mr. Daiji found an article I wrote in 2016 and said he wanted to republish it to let entrepreneurs get to know me again.

This article is a simple one, just my thoughts after reading “Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic Future”. Every time I read the book, I get excited and often think deeply. The book tells the complete story of Elon Musk creating SpaceX and Tesla, but does not include his newest projects, Boring Company and AI research that were underway last year.

The book reveals one message throughout, which is that Musk is an idealist, and when most people do not understand or approve of you, it is not because you are wrong, but because you are destined to be different.

Entrepreneurship is the path for idealists.

Beforehand: Recently, while re-reading “Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic Future”, I experienced the electric car section again and felt that the process of creating cars was simply an incredible obstacle. It is necessary to let the whole world know that Rome wasn’t built in a day, and neither was Tesla!

2003-2005, Founded in the Beginning

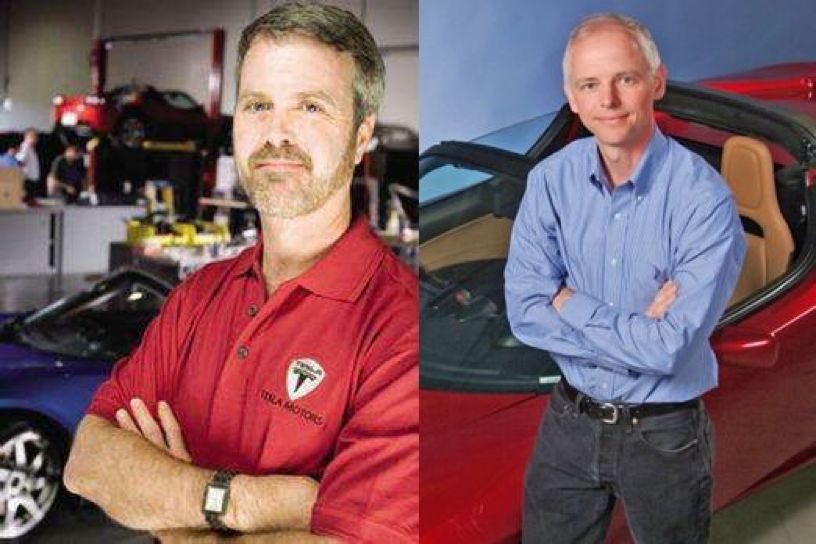

Tesla was founded on July 1, 2003, by co-founders Martin Eberhard and Marc Tarpenning. In 2004, they convinced Musk to become a major shareholder of Tesla for $6.5 million. Before this, Musk had already met JB Straubel and gave him some money to design an electric car in his own studio. Thus, these two fanatical electric vehicle teams came together with Musk’s intervention.

Tesla’s founders only intended to assemble the already produced AC propulsion company’s engine with their own batteries into the chassis of Lotus Elise sports cars, they did not intend to rely solely on their own resources.AC Propulsion was an electric car company with cutting-edge technology at the time. In 1997, they released a Tzero prototype, which could accelerate from 0 to 100 km/h in just 4.9 seconds (yes, electric cars had this performance 20 years ago). Initially, Musk had hoped to help AC Propulsion mass-produce the Tzero, but unfortunately, they were not interested. Therefore, Musk decided to buy the technology and build an electric car by himself. Tesla obtained the relevant power technology license.

Their plan was to buy transmissions from Europe and assemble them in Asian factories, while Tesla engineers focused solely on developing the battery system.

Research and development work began in October 2004, and they built a prototype named Roadster just five months later. This prototype met several requirements: purely electric and suitable for commuting. As a result, Musk happily invested an additional $9 million to continue with the project, with production anticipated to begin in 2006.

However, on July 4, 2005, while the engineering team was celebrating Independence Day at the home of Martin Eberhard, they suddenly thought of setting fire to the Roadster battery to see what would happen. After all, this car had 7,000 lithium batteries connected together. They tied 20 batteries together and lit the fuse, but the batteries flew out like rockets. This experiment frightened Tesla’s engineers, as it was difficult to imagine what would happen if all 7,000 batteries caught fire or exploded.

Musk immediately sent a team of experts to study battery ignition. After destroying thousands of batteries, engineers found a way to prevent battery burnout, making significant progress in safety.

After solving the battery safety issue, the Tesla team then selected a design that would differentiate their product from Lotus sports cars. They aimed to create a sports car with a comfortable riding experience. Musk had a significant influence on this matter and contributed many ideas, particularly regarding his desire for his then-wife, Justine, to feel comfortable when riding in the car (note: Model X has seven seats because Musk had five kids and a family of seven).

2006-2007: A long process of polishing

In May 2006, a quarter past the scheduled production time, Tesla constructed the first Roadster black prototype, EP1. This car won Tesla another $40 million in venture capital.Two months later, Tesla built another red prototype car and sent both cars to participate in a car show. People flocked to it and praised the Roadster, many of whom test drove the EP1.

Perhaps out of awe for the new things (chuckles), they ignored the fact that the car needed a professional driver (Strossmayer) and had to be cooled down every five minutes, still expressing their enthusiasm for buying it when it was available.

EP1 has an acceleration performance of 4 seconds per 100 km, a range of 250 km, and a price of $90,000. Musk said at the event that all the previous electric cars were terrible, and that a low-cost, four-door, four-seater model is expected to be launched within three years with an estimated price of $50,000.

This was Tesla’s first appearance in front of the media and was reported by The New York Times. Eberhard said that mass production would be delayed until the end of 2007 and announced Tesla’s business strategy of producing high-end electric vehicles first, using the money earned to produce more affordable models to promote the popularization of electric cars.

After this exposure, Tesla’s popularity skyrocketed, and everyone tried their best to obtain the qualifications to buy Tesla, willing to pay a huge deposit. Tesla then participated in many exhibitions and made reservations on site, receiving millions of dollars in funding. This can also be considered as a precursor to crowdfunding.

Then, the engineers took the car to the Nurburgring track for testing. (Does this sound familiar?)

In 2007, due to differences in the management of the company, Musk removed Eberhard from the CEO position and only let him be the chief technology officer. The latter eventually left angrily, and the two became enemies. During this period, Tesla encountered the first major problem with mass production: the stability of the transmission. Tesla commissioned Xtrac of England to produce a two-speed gearbox, which was thought to have been very smooth outsourcing, but the first gearbox they produced lasted only 40 seconds. Early gearboxes could not meet Tesla’s engineering requirements for speed.“`markdown

In January 2008, Tesla engineers had to solve the transmission problem themselves, as traditional Detroit carmakers refused to provide the top teams for Tesla.

Different powers from Silicon Valley and Detroit, one with freedom and passion for innovation, the other with experience and authority, showed completely different styles on the same matter.

The mass production setback made Musk realize the importance of company management issues. He hired professional consultants to investigate the company’s problems. They believed that if the Roadster, which costs $60,000, was designed and produced in the current way, the actual cost would be $200,000. The biggest problem was the astonishing cost of equipment and raw materials.

After Eberhard left, the board appointed Michael Marx as interim CEO. After some restructuring measures, the company’s operations improved. However, Marx and Musk still had major differences on the overall plan for the company.

Marx hoped to operate Tesla into a high-quality asset and sell it at a good price. But Musk wanted to do something in the field of electric cars from the very beginning, so he never considered selling the company regardless of the current difficulties.

Therefore, at the end of 2007, Tesla changed its CEO again.

Frequent personnel changes always have an impact on a company’s development. For a start-up company, it is easy to encounter such problems with the founding team’s disagreements. Only someone with firm willpower and the ability to consider from the company’s perspective can truly lead the enterprise to the path of growth.

Musk began to frequently expose Tesla in the media and promised everyone that they could deliver in early 2008. After all, many reservation holders had waited for a year. Musk’s firm attitude and abundant enthusiasm gradually dispelled everyone’s previous doubts, and very few people asked for refunds during the waiting period. It’s quite touching to think about people’s tolerance and love for new things.

By 2008, Tesla had reached a moment when it needed to make a breakthrough, as it was unacceptable for its mass-produced cars to be undelivered. Investors and consumers were watching closely.

“`

# 英文 Markdown Text

Elon Musk also began to take tough measures in the automotive industry, demanding employees to increase their workload and reduce costs, while he sent his private plane to the UK to collect related raw materials for the carbon fiber body problem and to send it to the French factory to ensure progress, similar incidents were common. Musk demanded that employees must also work on weekends. After being opposed, he said that everyone would have enough time to accompany their families after the company went bankrupt.

This tough work style caused Tesla to lose some valuable technical talents during this period, but the company’s powerful brand appeal continuously attracted outstanding talents from Silicon Valley, and overall, Tesla has always been short of people. But it lacked money.

2008: Tesla in the storm

In 2008, Tesla ran out of money.

The R&D cost of the Roadster was as high as 140 million US dollars, far exceeding the 25 million US dollars in the 2004 business plan. In 2008, American car companies went bankrupt one after another during the financial crisis, and Tesla found it difficult to convince investors to invest more money.

In June 2008, Musk divorced his ex-wife. The public opinion basically stood on Justin’s side. Justin opened a blog to disclose the details of their relationship and divorce, which made Musk in the center of the vortex of divorce scandal. In July, Musk realized that his money was only enough to support Tesla until the end of the year.

On the other hand, the third launch of Falcon 1 by SpaceX failed for the third time, which became a shadow on Musk’s public opinion and topic. Fortunately, the fourth launch in September was successful, which somewhat raised the public’s confidence in Musk. But these are not enough to dispel concerns about Tesla’s fate.

The economic crisis of Tesla was well known outside the company. Silicon Valley even launched a countdown to Tesla’s death.

“Musk himself admitted that Tesla’s economic crisis, divorce case, and the publicity of the third rocket launch failure, and his ex-wife’s constant revelations on the blog, put huge pressure on him, and he even felt that he could not live anymore.”

At the end of 2008, when Musk was in the most embarrassing situation, he could not afford Tesla’s monthly expenses of 4 million dollars, and he could only borrow money from friends – in the name of investment, and launched multiple fund-raising projects, such as selling the shares of other companies, and asking NASA to approve it for Space X. At the same time, he lobbied Tesla shareholders to invest again.

On the eve of Christmas, Tesla completed this financing. If it was a few hours later, Tesla may have gone bankrupt.

[Paragraph Insertion: I often think about Christmas in late 2008. For Musk, it must have been an unforgettable moment in his life. He also mentioned his collapse during some later interviews. Looking back on life, it may be necessary to mark the significance with some moments of deep bone pain, to highlight the value of life and the nobility of ideals.]

In 2008, the Roadster finally went into production, and the Model S was also unveiled to the public and received rave reviews. In 2009, Tesla received a $456 million loan from the US Department of Energy to produce the Model S. After surviving the life-and-death situation during the Christmas period of 2008, Tesla finally saw the light of day and received real social recognition.

In the process, Elon Musk used all his personal wealth and energy to strive for the hope of Tesla’s survival. This experience is very touching, and it is hard not to think of the new forces in car-making that have emerged today. Many similar scenes also make people smile.

In the past year of 2016, we have seen many conceptual or pre-production cars launched by companies. It can be generally recognized that because of the basic absence of patents by predecessor companies such as Tesla in automotive design and development, as long as there is enough money to recruit talents, good cars can be designed.

However, mass production is the biggest challenge for these Internet-based entrepreneurs. Just look at the high supply chain costs, engineering difficulties in personalization, equipment stability and personnel management problems experienced by Tesla. Each of which could cause a new company to collapse.

Now another year has passed, and some entrepreneurs have brought out their own products, demonstrating their sincerity to the market and consumers, and partially or fully fulfilling their promises. I believe most people feel how difficult it is to make cars, and how high the requirements are for the system of a company involving various aspects.

Even Tesla’s own products have been constantly iterated and improved over the past few years. As a large-scale consumer product, any detail of a car or electric car will be repeatedly verified over an extremely long usage cycle. Achieving a perfect balance between product design, workmanship, quality, and experience, and achieving an approximate balance between cost and revenue, are all very difficult.

Therefore, I think those entrepreneurs must now have enough reverence for this ancient and innovative industry of automobiles.

Otherwise, as the saying goes, Rome wasn’t built in a day.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.

*

*